Examine the B.Tech AKTU Quantum Book Short Question Notes on Advanced Concrete Design. Explore the world of structural engineering, analysis, and design for strong and innovative concrete structures.

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Wireless and Advanced Concrete Design: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 4th Year * Aktu Solved Question Paper

Unit-I: Introduction to Water Tanks (Short Question)

Q1. Define the term tank and classify them.

Ans. Tank: Tanks are structure that are commonly used to store water. Example: Water tank, Overhead tank, etc.

Type: There are three types of tanks:

- i. Tanks resting on ground.

- ii. Underground tanks.

- iii. Elevated tanks.

Q2. Define control joints.

Ans. Control joints are joints that are installed to prevent concrete cracking.

Q3. What are the different types of control joints ?

Ans. Following are the types of control joints :

- i. Contraction joints.

- ii. Expansion joints.

- iii. Sliding joints.

- iv. Construction joints.

Q4. Discuss joint in water tank.

Ans. The joint symbolises a break in either the concrete or the reinforcement, or both the reinforcement and the concrete.

Q5. Define contraction joint.

Ans. This is a joint in which a purposeful discontinuity in concrete or concrete and steel is provided with no initial gap.

Q6. Define expansion joint.

Ans. Expansion joints are designed to support either structural expansion or contraction by providing a complete discontinuity in both concrete and steel.

Q7. How will you define the sliding joint ?

Ans. Both the reinforcement and the concrete are completely discontinuous. Joint sealing chemicals are used to seal the joint. This junction is located near the base of the water tank’s walls.

Q8. What are the types of ground reservoir ?

Ans. Following are the types of ground reservoir:

- i. Underground storage reservoir (USR).

- ii. Ground storage reservoir (GSR).

- iii. High ground level storage reservoir (HGLR).

Q9. Define construction joints.

Ans. These concrete joints were developed for convenience in construction, and particular precautions were adopted to achieve subsequent continuity without allowances for further relative movement.

Q10. What is temporary open joint ?

Ans. These are the gaps that are temporarily left between the concrete neighbouring parts of a structure and are filled with suitable materials after a reasonable period and before the construction is put into service.

Q11. What are the different methods which are used in the designing of tanks ?

Ans. Following are the different methods:

- i. Reissner’s method.

- ii. Carpenter’s simplified method.

- iii. Approximate method.

- iv. IS code method.

Q12. Mention the important factors that must be considered while designing a RCC tank.

Ans. Following are two important factors to be noted in the design of an RCC tank :

Strength: The structure is designed so as to have a desired strength.

Watertightness: It is essential to avoid shrinkage fractures in the tank walls. This is accomplished by using distributed reinforcement that accounts for at least 0.3 percent of the wall’s gross area.

Q13. What are conditions under which the walls of underground water tanks designed ?

Ans. Following are the conditions for design the water tank:

- i. The walls of an underground tank are subject to water pressure from the tank’s water storage and earth pressure from the surrounding earth.

- ii. Extreme situations occur when the aforementioned pressures work independently.

- iii. The highest possible level of the water table should also be investigated, and plans should be established to keep the tank safe when the surrounding earth is expected to be charged with water.

Q14. Mention the reinforcement details that should be provided in a water tank.

Ans. Steel Reinforcement: According to IS code:

- i. Minimum Reinforcement: For sections up to 100 mm thickness, the minimum reinforcement in walls, floors, and roofs in each of the two directions at right angles shall have an area of 0.3 percent of the concrete section in that direction.

- ii. Minimum Cover to Reinforcement: The minimum cover to all reinforcement for liquid faces of parts of members either in touch with the liquid or covering the space above the liquid (such as inner faces of slab) should be 25 mm or the diameter of the main bar, whichever is greater.

Q15. What do you mean by base slab?

OR

Define bottom slab of tank.

Ans. The base slab supports the wall and is supported by earth. Through bearing, the weight of the water is directly transferred to the soil. The lateral surge of water in the walls creates a tensile stress in the foundation slab.

Q16. Write the forces which act on base slab.

Ans. Following are the forces act on base slab:

- i. Upward soil reaction.

- ii. Horizontal tension from walls.

- ii. Bending moment from walls.

Q17. Discuss the parameters which deal with the designing of rectangular tank.

Ans. Following are the parameters designing of rectangular tank:

- i. Design of vertical walls.

- ii. Design of base slab.

Q18. List our useable type of water tanks.

Ans. Following are the various types of water tanks:

- i. Circular tanks.

- ii. Rectangular tanks.

- iii. Spherical tanks.

- iv. Intze tank.

- v. Circular tanks with conical bottoms.

Unit-II: Design of Overhead Water Tanks (Short Question)

Q1. Define staging.

Ans. The structure can be supported directly on the ground, underground, or on a staging. The staging could be a beam and column arrangement or a circular shaft.

Q2. Define the term dome.

Ans. A dome can be used as a roof or a floor in circular tanks. A dome is a shell formed by rotating a regular geometrical curve around one of its axes.

Q3. Write the name of force which acts on the horizontal rings of dome.

Ans. Following are the two forces act on the horizontal rings of dome:

- i. Meridional thrust.

- ii. Hoop compression or tension.

Q4. Define ring beams.

Ans. Ring beams are tank beams that are supported by the wall or floor. In the case of over-the-head circular water tanks, the wall may be supported by a circular ring beam, which is supported by columns.

Q5. Why we provide steel ladder on a side of tank?

Ans. A steel ladder is supplied within the tank for cleaning and maintenance purposes, among other things.

Q6. Define meridional thrust.

Ans. Consider the dome to be constructed by a sequence of horizontal rings of decreasing diameters stacked one on top of the other. As a result, when a load is applied to the dome, it is resisted by these horizontal rings. One ring will be thrust against the other. The meridional thrust is the name given to this force.

Q7. Explain the ring girder.

Ans. This will be built to protect the tank and its contents. The column will support the girder. The girder should be constructed to withstand bending and torsion.

Q8. Discuss the parts of small overhead circular tanks.

Ans. Following are the parts of small overhead circular tanks:

- i. Cylindrical wall.

- ii. Circular slab.

- iii. Supporting beam and columns.

Q9. What is an Intze tank ?

Ans. In the case of big diameter tanks, a cost-effective approach would be to lower the diameter at the bottom with a conical dome. This type of tank is known as an Intze tank and is widely utilised.

Q10. Discuss the parts of Intze tank.

Ans. Following are the parts of Intze tank:

- i. Top spherical dome.

- ii. Top ring beam.

- iii. Cylindrical wall.

- iv. Bottom ring beam.

- v. Conical shell.

- vi. Bottom spherical dome.

- vii. Bottom circular girder.

Q11. Differentiate between the overhead tank and underground tank.

Ans. i. The increased demand for above-ground structures is mostly owing to their cheaper initial cost.

ii. Because they require substantially less excavating, filling, and paving than underground storage tanks, they are much easier and less expensive to install.

Q12. How wind load affect the overhead water tanks?

Ans. i. Due to the height and shape of the water tank, wind load becomes an important load component when analysing and constructing a water tank since it causes lateral displacement.

ii. Lateral displacement in the water tank as a result of wind load causes sloshing and extra vibrations.

Q13. Why free board provided in the water tank?

Ans. Following are the objectives to provide free board:

- i. Safety: If a person is inside for maintenance and the cover is closed, the person can survive by keeping the head in the area between the roof and the water.

- ii. Air Ventilation: There shall always be free and fresh air on the top of water.

Unit-III: Introduction to Prestressing (Short Question)

Q1. Define the term prestressed concrete member.

Ans. It is a concrete member in which internal stresses are produced in a deliberate manner to counterbalance the stresses caused by superimposed loads to a desired degree.

Q2. Discuss the advantages of prestressing concrete.

Ans. Following are the advantages of prestressing concrete :

- i. Prestressed concrete is devoid of cracks when subjected to service loads.

- ii. Prestressed concrete prevents steel corrosion when the structure is exposed to the elements.

- iii. Because prestressed concrete does not crack, it is more predictable than typical reinforced concrete in various ways.

Q3. What are the processes used to induce prestress in a structure ?

Ans. Following are the two processes used to induce prestress in a structure:

- i. Pre-tensioning.

- ii. Post-tensioning.

Q4. Define cracking moment.

Ans. The cracking moment is the bending moment at which visible fissures emerge in a prestressed concrete member.

Q5. What is anchorage ?

Ans. As the name implies, anchorage is a component of the post-tensioning system that is used to anchor the tendons into the concrete while terminating or merging two tendons. Once the stressing process is complete, the main role of anchoring is to transfer the stressing force to the concrete.

Q6. What is the need of prestressing ?

Ans. The goal of using prestressed concrete is to increase the tensile strength of concrete by creating an internal compressive stress, which counteracts the tensile stresses induced by service loads on the structural element in part.

Q7. State the difference in load carrying mechanism in flexure under working condition between RCC and PSC.

Ans. i. Steel has an active part in prestress concrete members. Whether there is an external load or not, stress in steel prevails. Steel, on the other hand, plays a passive role in RCC. The stress in steel in an RCC member is determined by the external loads; if there is no external load, there is no stress in steel.

ii. In prestress concrete, steel strains are almost constant, whereas in RCC, steel stresses vary with the lever arm.

iii. Prestress concrete has higher shear resistance, but RCC has lower shear resistance.

Q8. Define jacking stress.

Ans. It is the actual pull in the wire before the anchorage near the jack. The apparent jacking tension is always less than this stress.

Q9. What is P-line and C-line ?

Ans. P-line: It is nothing but the tendon line itself. The line of action of the P-force is called the P-line.

C-line: C-force is the compressive force acting on concrete. The line of action of C-force is called C-line.

Q10. Name different method used for post-tensioning system.

Ans. Following are various methods used for post-tensioning :

- i. Freyssinet system

- ii. Magnel-Blaton system.

- iii. Gifford-Udall system.

- iv. Electrical prestressing.

- v. Lee-Mccall System.

Q11. Define partial prestressed.

Ans. A member is considered to be partially prestressed when modest tensile stress is permitted in the tension flange of a prestressed flexural member without losing its performance under the condition of design live load.

Q12. What is length effect ?

Ans. The length effect refers to the amount of friction encountered in a straight tendon as a result of minor duct defects. The conduit intended for the straight tendon is not perfectly straight in practise.

Q13. What checks are involved in limit state of serviceability ?

Ans. Following are the checks involved in limit state serviceability :

- i. Cracking.

- ii. Deflection.

- iii. Maximum compression.

- iv. Durability.

- v. Vibration.

Q14. Explain disadvantages of prestressed concrete.

Ans. Following are the disadvantages of prestressed concrete :

- i. It uses high strength concrete and steel.

- ii. It may require complicated formwork.

- iii. Labour cost may be high.

- iv. It requires a better quality control.

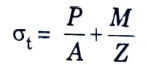

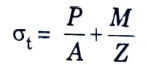

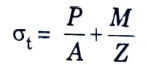

Q15. Write the general formula for calculating the stress at top fibre of the beam.

Ans.

where,

P = Direct load.

A = Cross-sectional area.

M = Bending moment.

Z = Section modulus.

𝛔t = Top fibre stress.

Q16. Which method of prestress is preferred in a prestressed concrete bridge ?

Ans. Post-tensioning.

Q17. What are the advantages of Fressinet system ?

Ans. Following are the advantages of Fressinet system :

- i. It is not expensive to secure the cables.

- ii. The desired stretching power is soon obtained.

- iii. The plugs can be left in the concrete as long as they do not protrude past the end of the member.

Q18. Describe the disadvantages of Fressinet system.

Ans. Following are the disadvantages of Fressinet system:

- i. A cable’s wires are all stretched together. As a result, the tensions in the wires may not be same.

- ii. The jacks utilised are large and costly.

Q19. List the various types of tensioning devices used in prestressed concrete.

Ans. Following are various types of tensioning devices used in the prestressing :

- i. Prestressing bed or casting bed,

- ii. Hydraulic jacks,

- iii. Anchoring devices,

- iv. Molds or casting molds,

- v. Tendon profile fixer,

- vi. Spacer, and

- vii. Bearing plates.

Unit-IV: Losses and Design of Prestress Concrete Structures (Short Question)

Q1. Define loss of prestress.

Ans. The prestress force supplied to the member gradually decreases rather than remaining constant. The amount of force that is lost is known as loss of force, and the reduction in stress is known as loss of prestress, and it can range from 15% to 20%.

Q2. Illustrate the losses in prestress.

Ans. Following are the losses in prestress:

- i. Loss of prestress during the tensioning process.

- ii. Loss of prestress at the anchoring stage.

- iii. Losses occurring subsequently.

Q3. Enlist all the losses of prestress occurring subsequently.

Ans. The losses which occur subsequently are as follows:

- i. Loss of stress due to shrinkage of concrete.

- ii. Loss of stress due to creep of concrete.

- iii. Loss of stress due to elastic shortening of concrete.

- iv. Loss of stress due to relaxation of steel.

Q4. What do you mean by elastic shortening of concrete ?

Ans. When prestress is transmitted from steel to concrete, the concrete member is also shortened. This is referred to as elastic concrete shortening.

Q5. Write short note on creep.

Ans. Creep is the feature of concrete that causes it to deform over time when subjected to prolonged loads at unit stresses within the acceptable elastic range.

Q6. How will you define the shrinkage of concrete ?

Ans. It is described as an increase in the volume of concrete members. It is affected by atmospheric humidity, the type of cement and aggregate used, and the passage of time, but it is unrelated to the application of load.

The loss of prestress due to shrinkage may be expressed as:

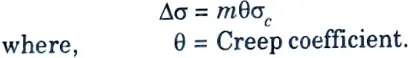

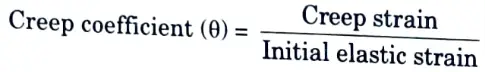

Q7. What is creep coefficient ?

Ans. It is defined as the ratio of creep strain to the initial elastic strain.

They is given by,

Q8. How to minimize the loss of prestress due to friction ?

Ans. Loss of stress due to friction can be minimized by resorting of the following:

- i. Through the use of lubricants in unbonded beams.

- ii. Tendons can be tugged from both ends.

- iii. At bends, the radius of curvature should be as large as possible.

- iv. The cables may be routed through metal tubes at the ends.

Q9. Why loss of prestress occurs due to friction?

Ans. Following are two reasons of loss of prestress occurs due to friction:

- i. Due to curvature effect.

- ii. Due to length or wobble effect.

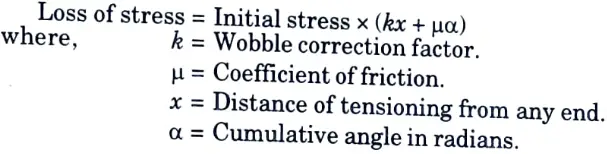

Q10. Discuss the formula due to loss of friction in beam.

Ans.

Q11. Compare the loss of prestress due to elastic shortening in pre-tensioned and post-tensioned members.

Ans.

| S. No. | Pre-tensioned | post-tensioned |

| 1. | When prestress is transferred from steel to concrete in pre-tensioned beams, the concrete member shortens together with the steel, resulting in prestress loss. | This loss does not occur in post-tensioned members if all tendons are stressed at the same time, but there will be a loss of prestress if all tendons are not pressured at the same time. |

| 2. | Loss of prestress which may range from 3 to 6 %. | This loss is calculated as, σs = mσc |

Q12. Why are the anchor plates provided in post-tensioning ?

Ans. Anchor plates are installed at the ends of the tendons to keep them stretched. End bearings, rather than bonds, convey the prestress force to the concrete.

Q13. What are the precautions taken when sloping tendons are used ?

Ans. When sloping tendons are used, the following precautions are taken:

- i. The tendon’s form is rounded at the place where it changes direction.

- ii. Special bearing plates or fixtures are provided to alleviate stress if the bearing stress is exceeded.

Unit-V: Design of Deep Beams and Corbels (Short Question)

Q1. Define the term deep beam.

Ans. As per IS 456: 2000, a beam shall be deemed to be a deep beam when the ratio of the effective span (l) to the overall depth (D), i.e., L/D ratio is less than

- i. 2.0 for simply supported beams.

- ii. 2.5 for a continuous beam.

Q2. How differ deep beams from shallow beams?

Ans. The key assumption in the case of shallow beams is that plane parts remain flat after bending, and hence the distribution of bending force across the depth is linear. Deep beams, on the other hand, have a non-linear stress distribution over their length.

Q3. What are the corbels ? Where are they used ?

Ans. A corbel or a nib is a small cantilever deep beam. Corbels are used to support enormous weights, such as crane or gantry loads, in industrial buildings. Corbels use strut-tie action to transfer loads to the supports.

Q4. What is the difference between deep beam and corbel?

Ans. Corbel differs from deep beam in a way that it is also designed for horizontal forces.

Q5. How would you analyze a corbel ?

Ans. Corbel load carrying ability is typically regulated by a shear failure mode. The methods available for shear analysis of corbels are mainly based on the shear friction notion or a truss analogy, together with concepts from plasticity theory.

Q6. Where do deep beams occur ?

Ans. Deep beams are used in retaining constructions such as silos, bunkers, and water tanks, where they must also withstand lateral stresses.

Q7. What is meant by shear friction ?

Ans. Shear friction is a term used to describe the process of reinforcing vertical fissures in a beam caused by shear in a deep beam, temperature, creep, or shrinkage.

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Advanced Concrete Design Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Advanced Concrete Design Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One View) | Student Result |

1 thought on “Btech Advanced Concrete Design KCE-073 Aktu Short Question Quantum Book Pdf”