Use Aktu Btech Quantum Notes to improve your understanding of Power System-I. Your exam preparation will be strengthened by these crucial, recurrent questions. Improve performance right away! Unit-5 Insulated Cables

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Power System-I: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 3rd Year * Aktu Solved Question Paper

Q1. Explain the basie introduction of insulated cable.

Ans.

- 1. Underground cables or overhead transmission lines can be used for the transmission and distribution of electrical power (insulated cables).

- 2. It is common knowledge that using overhead lines is impractical in densely populated areas like towns and cities.

- 3. Underground cables are used in these situations to transfer and distribute electrical energy.

- 4. An subterranean cable is just a conductor that has been properly insulated. Since insulation costs rise quickly as voltage levels rise, subterranean cables can only be utilized for low- and medium-voltage distribution.

Q2. What should be the desirable characteristics of insulating materials used in cables ? Also discuss general construction of cable.

Ans. A Characteristics of insulating materials:

- 1. Its insulation resistance needs to be extremely strong in order to prevent leakage current.

- 2. Its dielectric strength must be extremely strong to prevent electrical breakdown.

- 3. It ought to be adaptable.

- 4 It must be mechanically highly strong in order to endure the mechanical injuries.

- 5. It must not catch fire.

- 6. It ought to be non-hygroscopic to avoid absorbing moisture from the environment.

- 7. Acids and alkalis shouldn’t have any impact on it.

- 8. It needs to be strong enough to handle high breakdown voltage.

- 9. It should be capable of withstanding high temperatures.

B. The main insulating materials which are in use are:

- 1. Polyvinyl chloride (PVC)

- 2. Paper

- 3. Cross linked polythene

- 4. Vulcanised India Rubber (VIR)

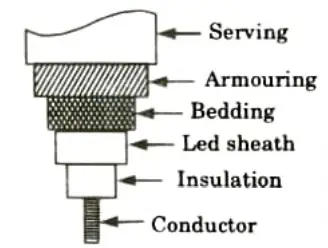

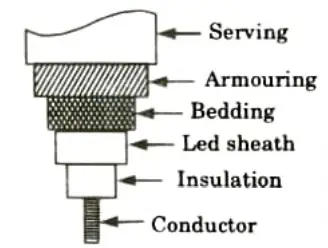

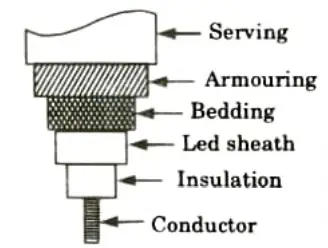

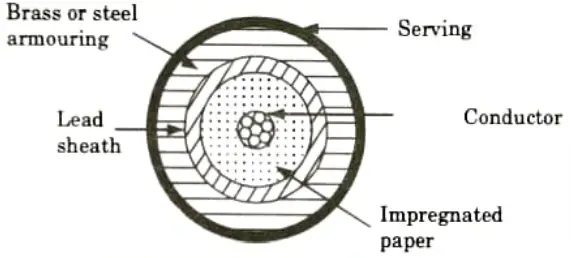

C. General construction of cable:

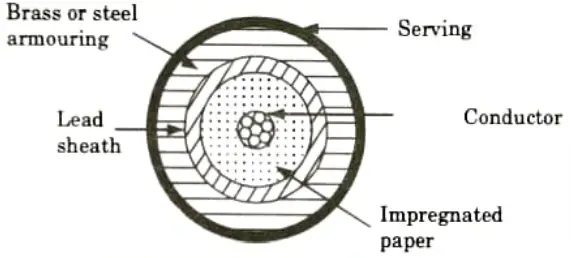

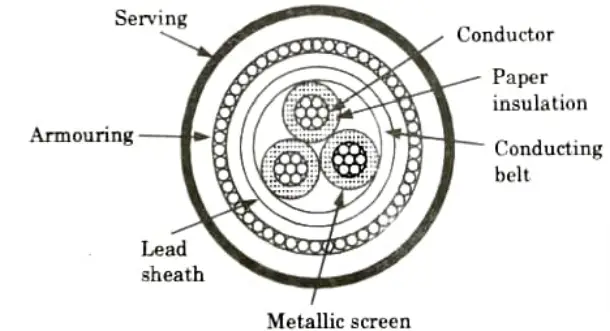

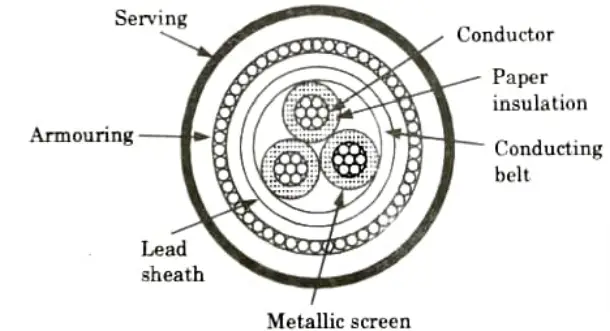

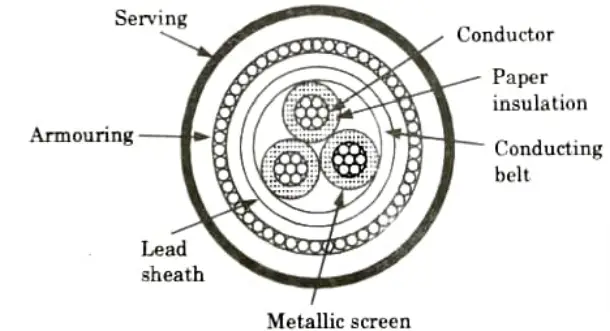

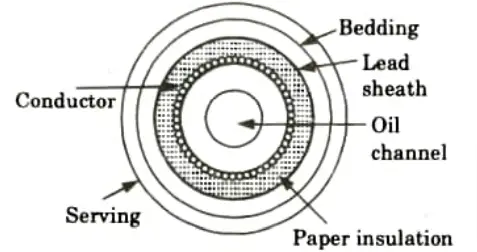

The Fig. shows the general construction of a cable. Its various parts are:

- 1. Conductor or core:

- i. There is only one conductor or multiple conductors in this part. Cores are another name for the conductors.

- ii. Copper or annealed aluminium are utilised as conductors. The stranding of the conductors gives the cable flexibility.

- 2. Insulation: Each conductor or core is protected by the appropriate thickness of insulation. Varnished cambric, vulcanized bitumen, and impregnated paper are the three most often used insulating materials.

- 3. Metallic sheath: There is a lead sheath or an aluminium sheath covering the insulated conductors. This offers mechanical protection, but its major function is to prevent moisture and other gases from getting to the insulation.

- 4. Bedding:

- i. A second layer known as bedding is placed on top of the metallic sheath. The bedding is made of paper tape mixed with a fibrous substance, such as jute fibers or hessian tape.

- ii. The bedding’s main function is to shield the metallic sheath from rust and damage caused by armouring’s mechanical effects.

- 5. Armouring: This layer, which is made up of layers of galvanized steel, shields the cable from mechanical harm.

- 6. Serving: Serving is the final layer over the armour. The armoring is shielded from atmospheric conditions by a layer of fibrous material, similar to jute cloth.

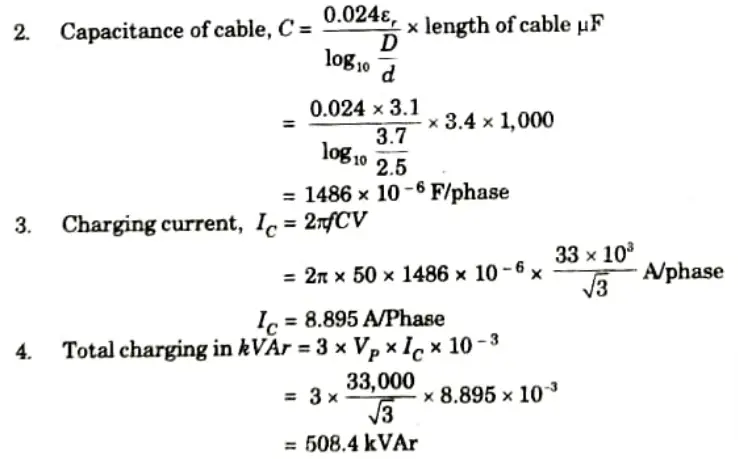

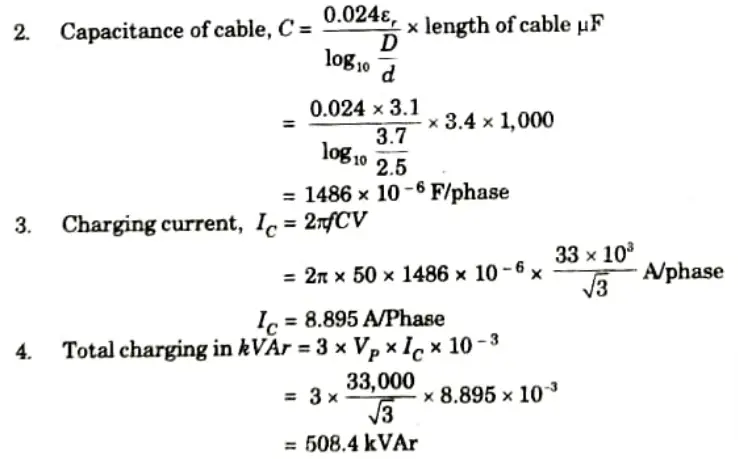

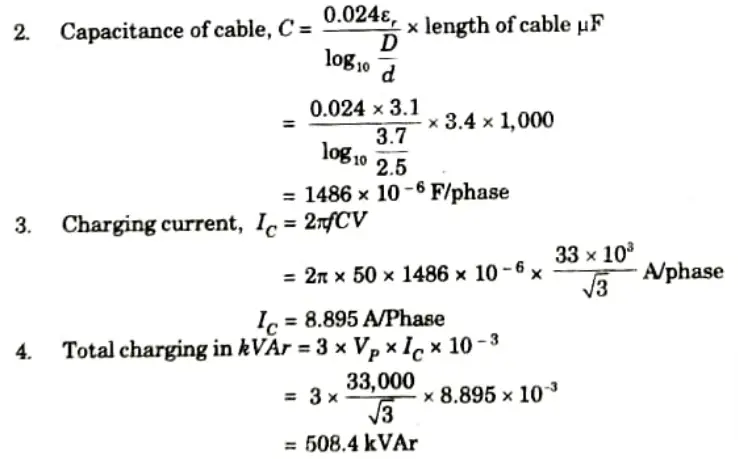

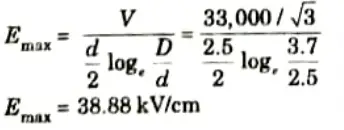

Q3. A 33 kV, 3-phase, 50 Hz underground line, 3.4 km long, uses three single core cables. Each cable has a core diameter of 2.5 cm and the radial thickness of insulation is 0.6 cm. The relative permittivity of the dielectric is 3.1. Find (i) maximum stress and (ii) total charging kVAr.

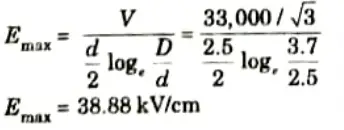

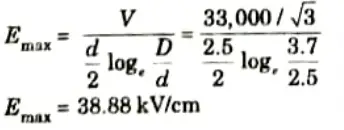

Ans. Given: d = 2.5 cm, thickness 0.6 cm, 𝜖r = 3.1

To Find: Maximum stress and total kVAr.

1. Internal diameter of sheath, D = 2.5 + 2 x 0.6 = 3.7 cm

5. Maximum stress in the cable

Q4. Give a comparison of an overhead line with underground cable as a medium of power transmission.

Ans.

- 1. Public safety: Because the wiring is underground, there are fewer potential hazards, making the underground system safer than the overhead system.

- 2. Initial cost: Due to the high cost of trenching, conduits, cables, manholes, and other specialized equipment, the initial cost of an underground system may be five to 10 times greater than that of an above system.

- 3. Flexibility: Because poles, wires, transformers, and other components can be simply moved in an overhead system to adapt to changing load circumstances, it is far more flexible than an underground system.

- 4. Faults: Due to the fact that the cables are buried underground, malfunctions in the underground system are extremely unlikely.

- 5. Fault location and repairs: In essence, the likelihood of a malfunction in a subterranean system is quite low. Yet, it is challenging to find and fix a malfunction in an underground system.

- 6. Current carrying capacity and voltage drop: In comparison to a subterranean cable conductor of the same material and cross-section, an overhead system may transport a lot more current. Moreover, the overhead system has a low voltage drop.

- 7. Useful life: An underground system has a substantially longer usable life than an above system.

- 8. Maintenance cost: Because to a lower likelihood of faults and service disruptions from wind, ice, lighting, etc., underground systems require far less maintenance than above systems.

Q5. Discuss in brief about the different types of cables.

Ans. The voltage level at which a cable is made and the insulation material, such as paper cotton, rubber, etc., are essentially what determine the type of cable.

Types of cable:

A. Low tension cable (L.T. cable):

- 1. They are utilized for voltage levels up to 6.6 kV.

- 2. These cables have paper insulation. Resin is occasionally used to increase viscosity and aid in preventing drainage.

- 3. The figure depicts the cross-section of a single core L.T. cable. It consists of a copper or aluminium stranded core that is circular in shape.

- 4. Impregnated paper is used to insulate the conductor, which is subsequently covered with a lead sheath and a layer of composite fibre material. After that, armour is installed, and a layer of fibrous composite material is applied once more.

B. Medium and high tension cables:

- 1. Three core cable makes up the three phase medium and H.T. cables. Three core cable, often known as multicore cable, is used for voltages up to 66 kV.

- 2. These cables are classified as:

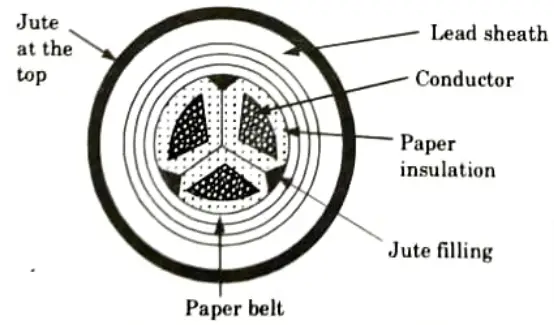

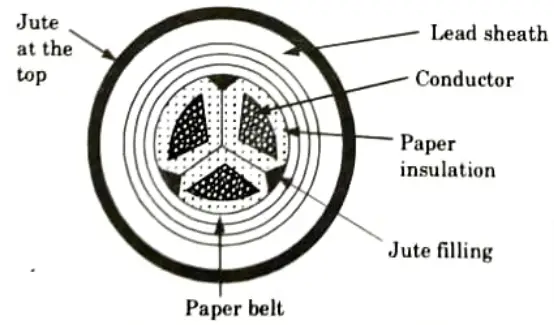

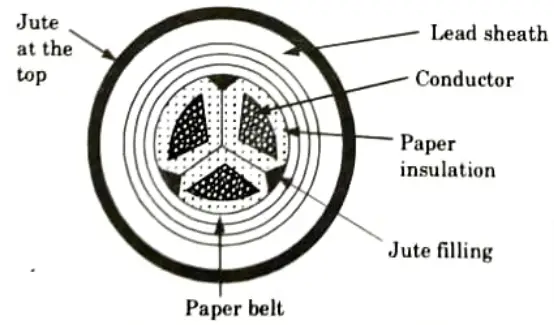

- a. Belted cables:

- 1. These are used for the voltage level upto 11 kV. The construction of belted cable is shown in Fig.

- 2. The cores are not symmetrical. With impregnated paper, the cores are kept apart.

- 3. A paper belt is used to belt the three cores together.

- 4. Fibrous material, such as jute, is used to cover the gaps. The cable now has a circular cross-section.

- 5. The lead sheath covering the belt provides mechanical strength and moisture protection for the cable.

- 6. A fiber compounded material that resembles jute is eventually used to cover the lead sheath.

- b.Screened type cables: These cables are used for the voltage levels of 22 kV and 33 kV. The two types of screened cables are :

- i. H-type cable:

- 1. This kind of cable doesn’t have a paper belt. Each conductor in this cable is covered with a metallic screen, often made of aluminium foil, and is insulated with paper. The building is seen in Fig.

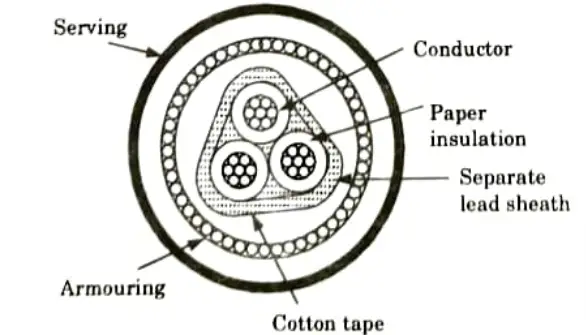

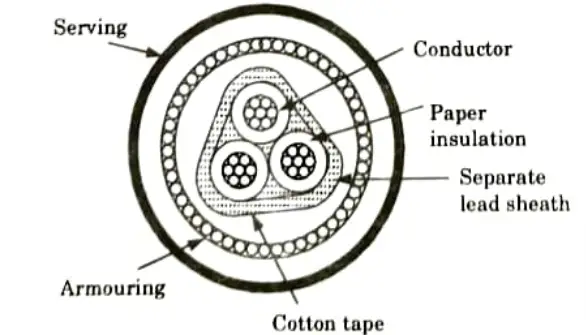

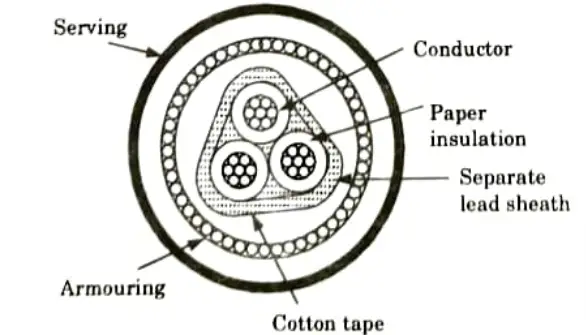

- ii. S.L type cable (Separate lead screened cable):

- 1. Each core of this cable is coated by a unique lead sheath after being insulated with impregnated paper.

- 2. Then there is a cotton tape covering the three cores together using a proper filter material.

- C. Super tension (S.T.) cables:

- 1. The S.T. cables are used for 132 kV to 275 kV voltage level.

- 2. Such cables using oil or gas under pressure are called pressure cables and are of two types:

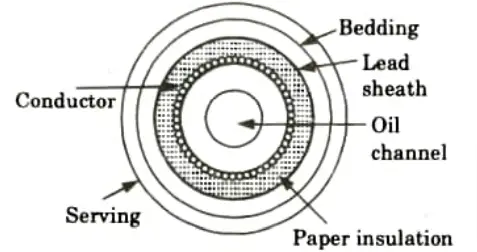

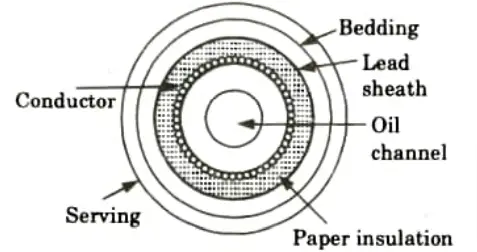

- a. Oil filled cables:

- 1. In the case of oil-filled cables, channels or ducts are present within or close to the cores and are used to circulate oil under pressure.

- 2. Fig. illustrates how a single core oil-filled cable is built. Although it is constructed around a hollow, cylinder, steel spiral core, it consists of concentric stranded conductor.

- 3. This hollow core serves as the oil’s conduit. In a factory, the oil channel is filled, and the pressure in the oil is maintained by connecting the oil channel to the tanks that are positioned at the proper distances along the cable’s journey.

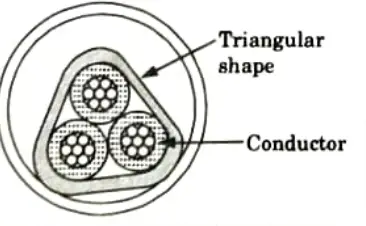

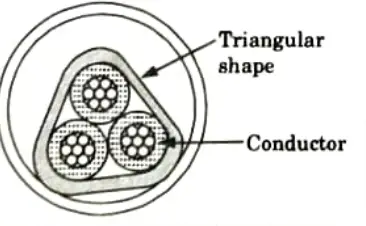

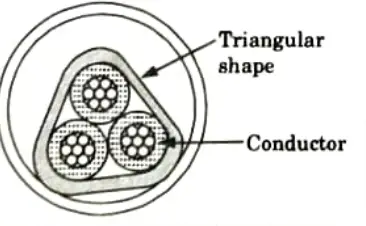

- b. Gas pressure cables:

- 1. In the case of gas pressure cables, a high pressure inert gas, such as nitrogen, is introduced. Between 12 to 15 atmospheres of pressure are present.

- 2. The ionization is completely destroyed as a result of the radial compression caused by the high pressure. Such cables also have a high operating power factor.

- 3. The segment of a gas pressure wire is depicted in the figure. The triangular cable is inserted within the steel pipe.

- 4. Nitrogen is pumped into the pipe at a pressure of 12 to 15. There are no beds or servers.

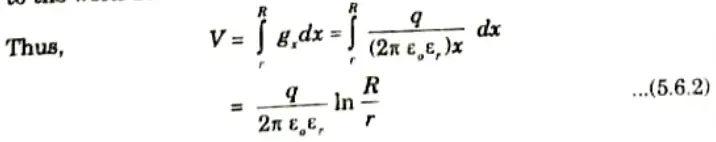

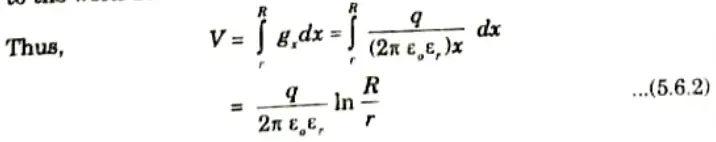

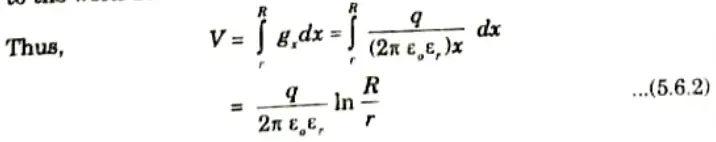

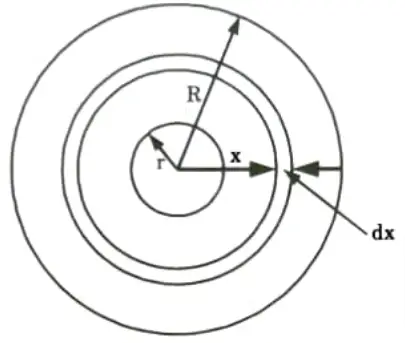

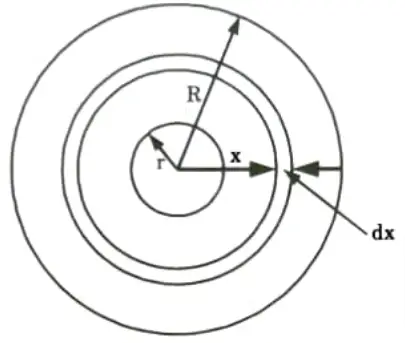

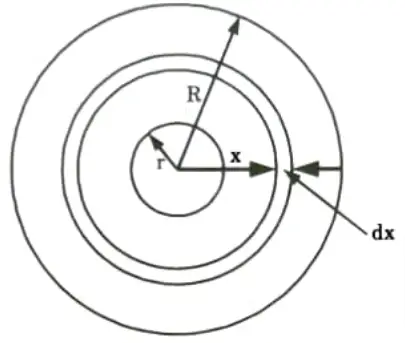

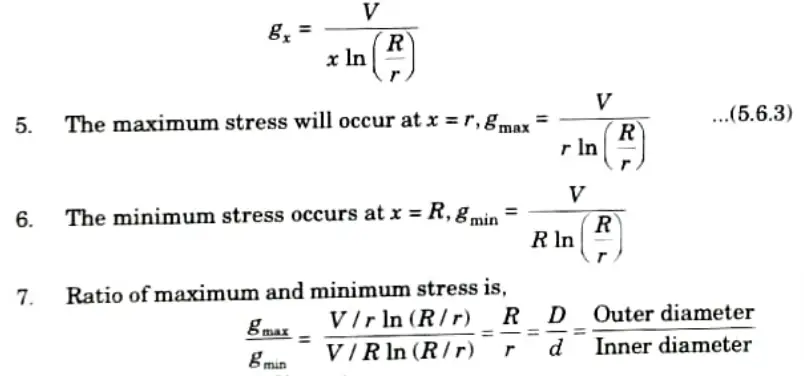

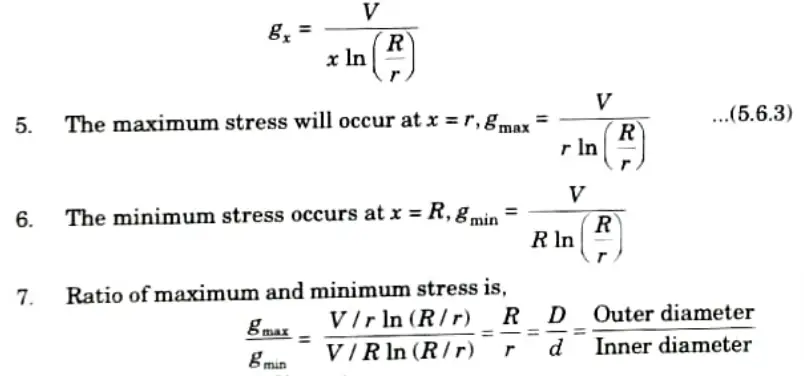

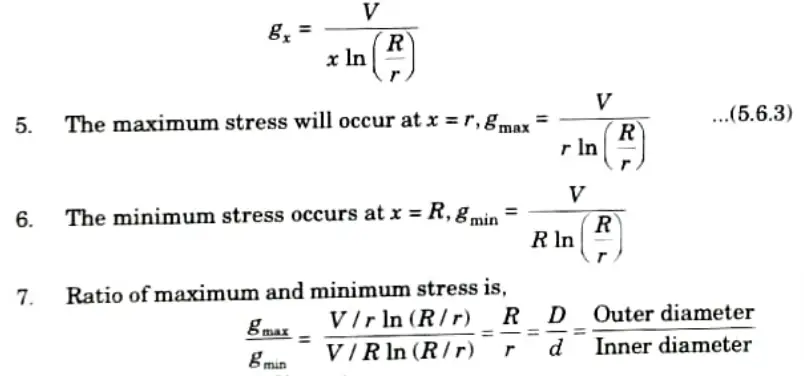

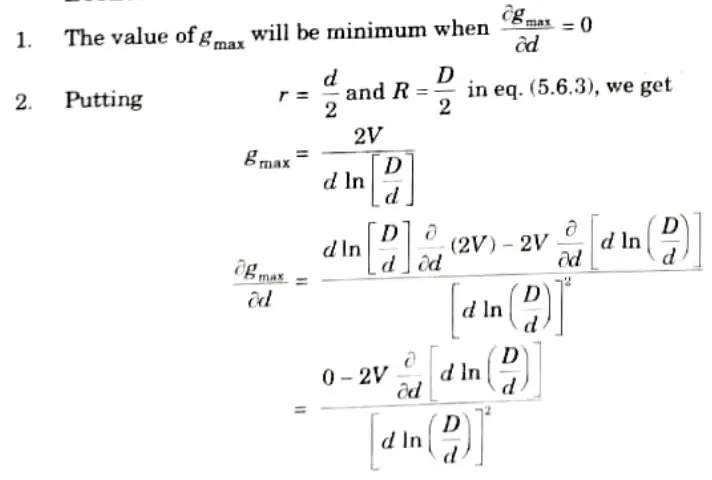

Q6. Derive expression for dielectric stress in a single core cable.

Ans.

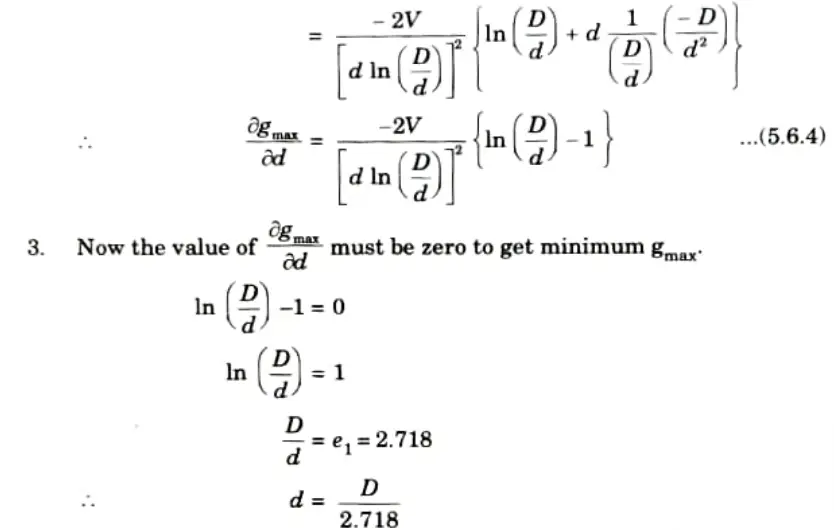

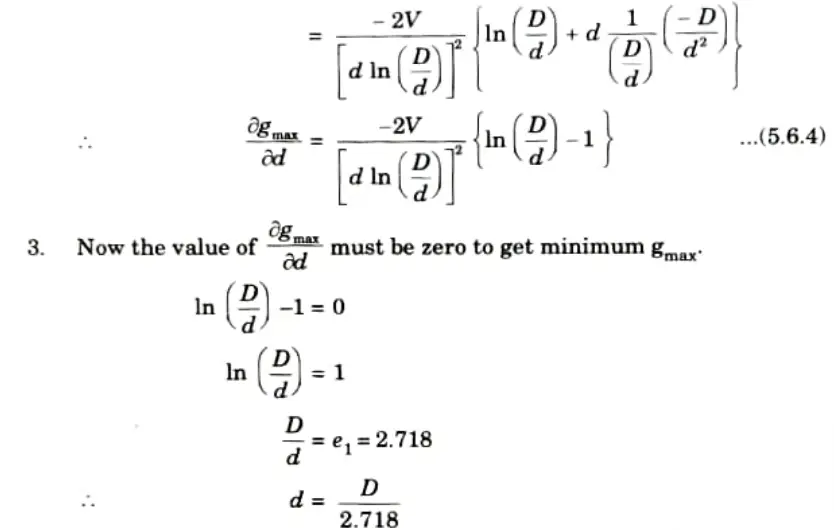

2. The electric flux density at a distance x from the center is,

and the electric stress is given by,

3. The effort required to transfer a unit charge from the conductor to the sheath is equal to the potential difference between the conductor and the sheath.

4. Combining eq. (5.6.1) and (5.6.2), we get

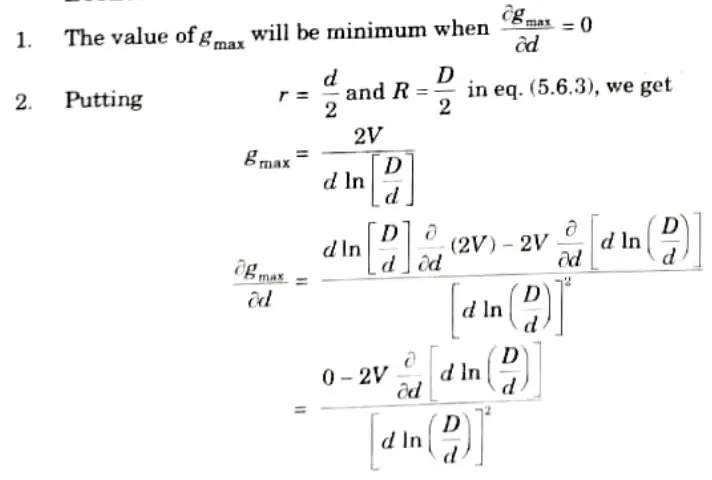

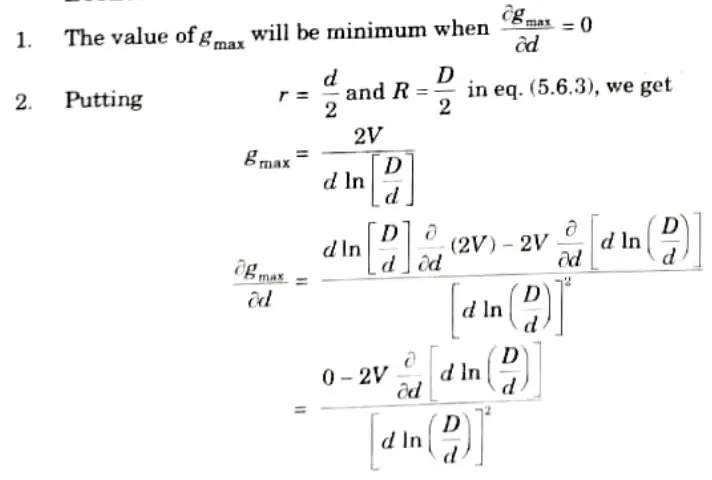

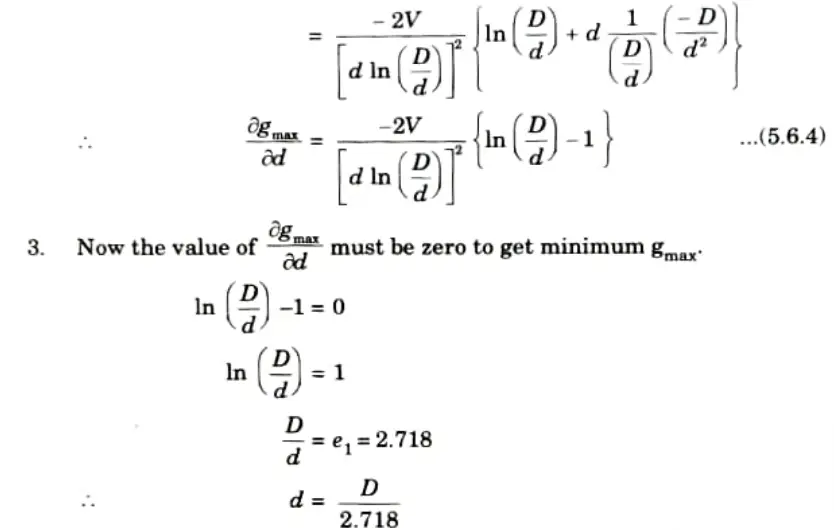

Economical core diameter:

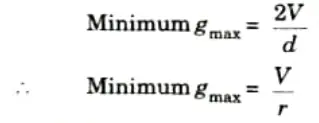

4. Hence, the core diameter must be 1/2.718 times the sheath diameter D so as to give the minimum value of gmax.

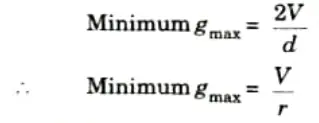

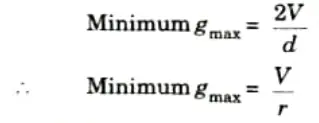

5. The value of minimum gmax is,

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Power System-I Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Power System-I Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One VIew) | Student Result |