Explore the world of Industrial Engineering with the B.Tech AKTU Quantum Book. Access crucial notes, frequently asked questions, and helpful insights to excel in this industry. Unit-4 Work System Design

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Industrial Engineering: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 3rd Year * Aktu Solved Question Paper

Q1. Write a short note on Taylor’s scientific management.

Ans.

- 1. In order to optimise output with the least amount of input, scientific management placed a strong emphasis on planning, standardizing, and improving human effort at the operational level.

- 2. Taylor thought that management should be based on measurement and facts rather than speculation.

- 3. The application of scientific knowledge and methodologies to the various facets of management and the issues that result from them results in scientific management.

- 4. Taylor believed that scientific management will increase both employee and company earnings by maximizing the productive efficiency of each worker.

- 5. Scientific management could be summarized as:

- i. Science, not rule of thumb,

- ii. Harmony, not discord,

- iii. Cooperation, not individualism,

- iv Maximum output, in place of restricted output, and

- v. The development of each worker to his greatest efficiency and prosperity.

Ans. Principles of motion economy related to the use of human body are as follows:

- 1. The two hands should initiate and finish their movements simultaneously.

- 2. Except from rest periods, the two hands shouldn’t be inactive at the same moment.

- 3. Motions of the arms should be made simultaneously, in opposite, symmetrical directions.

- 4. Hand and body mobility should be limited to the lowest classes that allow for satisfactory completion of the task.

- 5. Momentum should be used whenever possible to aid the worker, and it should be kept to a minimum so that it may be overcome by muscular exertion.

- 6. Smooth, continuous hand gestures with curved arcs are better to straight motions with abrupt direction changes.

- 7. Ballistic motions are quicker, simpler, and more precise than controlled or restrained motions.

- 8. Where possible, work should be organized to allow for an easy rhythm.

- 9. As few and closely spaced eye fixations as feasible.

Q3. What is work sampling ? Give the steps of work sampling.

Ans. A. Work Sampling:

- i. Definition:

- 1. Work sampling, also known as ratio delay study, is a method for determining how efficiently people or machines are used by collecting a large number of instantaneous observations at random periods.

- 2. The proportion of time that a process is in a particular state of activity can be estimated by dividing the number of observations of a given activity by the total number of observations.

- ii. Use of Work Sampling for Standard Time Determination: Establishing time requirements for both direct and indirect labour activities might benefit greatly from work sampling.

B. Steps of Work Sampling: Steps of work sampling are as follows:

- Step 1: Define the problem.

- 1. Describe the job for which the standard time is to be determined.

- 2. Indicate clearly which job-related activities would qualify a person to be in a “working” state and which actions would qualify a person to be in a “not working” condition.

- Step 2: Design the sampling plan:

- 1. Estimate satisfactory number of observations to be made.

- 2. Decide on the period of study, for example, two days, one week, etc.

- 3. Prepare detailed plan for taking the observations.

- Step 3: Contact the persons concerned and take them in confidence regarding conduct of the study.

- Step 4: Make observations regarding the operator’s working or non-working status at the predetermined random times. Determine the operator’s performance rating while he is in a working state. On the observation sheet, note both.

- Step 5: Gather additional information and document it. This comprises the operator’s daily beginning and stopping times as well as the overall quantity of parts produced that are of acceptable quality.

- Step 6: Calculate the standard time per piece.

Q4. Explain the basic principle and concept of achieving quality in design.

Ans.

- 1. The stringency of the specifications for the product’s manufacture affects the product’s design quality.

- 2. Consistent performance across the intended life span, as stated as rated output, efficiency, and overload capacity for specified service, is a requirement of excellent design.

- 3. It must take into account the potential failure modes brought on by stress, wear, distortion, corrosion, vibrations, etc.

- 4. Product design and development, however, is a continual process that leads to evaluation of a product based on determined user needs, their input following use, and progress in technology at a particular point in time in a given environment.

- 5. Factors affecting the quality of design are as follows:

- a. Types of Customer in the Market:

- 1. This includes “market research” on consumer spending patterns, pricing they are willing to pay, and product design preferences.

- 2. Yet, when it comes to capital goods, decisions are typically guided by factors like planned life, environmental conditions, reliability, maintainability, etc.

- b. Profit Consideration:

- 1. From company’s point of view, profit is more important.

- 2. It’s not required for the business to produce only high-quality goods.

- 3. To cater to various consumer types, items can be produced in a variety of grades to optimize profit.

- c. Environmental Conditions:

- 1. This is crucial in determining the design’s quality. For instance, an automobile radiator intended for equatorial use should be built to withstand higher ambient temperatures.

- 2. A well-built bus body with a reputation for reliability outside of the country was unable to endure local traffic patterns and road conditions.

- d. Special Requirements of the Product:

- 1. Better quality goods should generally have tighter tolerances and improved strength, fatigue resistance, life, and interchangeability of produced pieces.

Q5. Define standardization. Write down the applications of standardization.

Ans. A. Standardization: It is a temporary crystallization of the best feasible solution to a persistent problem, developed scientifically and methodically by combining the expertise of all people who are interested in the issue, and it should be followed. It is also subject to review and amendment by consensus.

B. Applications of Standardization:

- 1. Finished products, e.g., cars and televisions.

- 2. Subassemblies and components, e.g., automobile gearboxes and auto electric bulbs.

- 3. Standardization of materials, such as plain carbon and alloy steels, arc welding electrode core wires, etc. Direct materials as well as indirect materials (such as oils and greases).

- 4. Standardization of production equipment, such as those of machine tools, presses, welding equipment, etc.

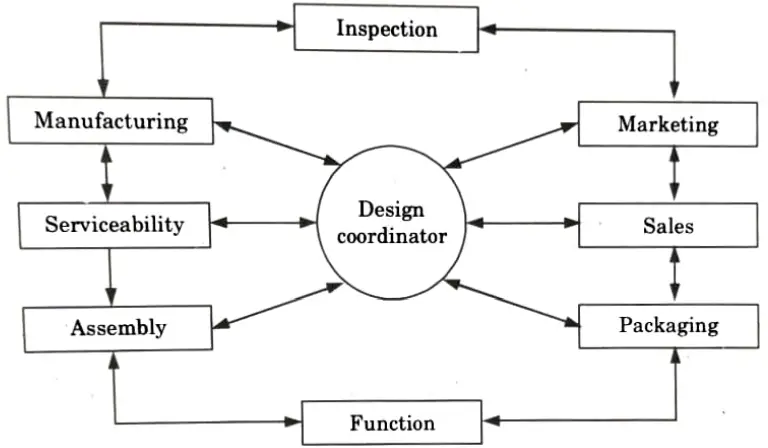

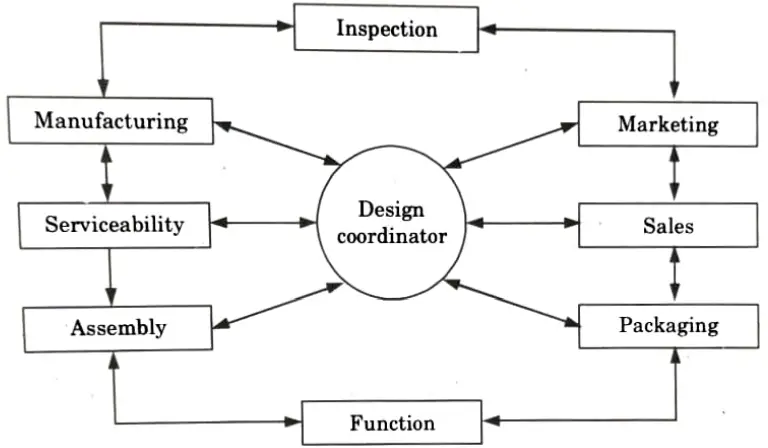

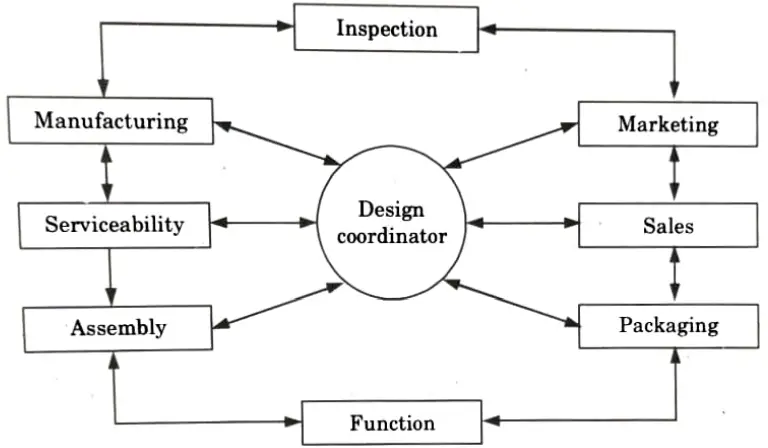

Q6. What do you understand by the term concurrent engineering?

Ans.

- 1. Concurrent engineering is also known as simultaneous or parallel engineering.

- 2. Concurrent engineering is a flexible method that ensures the product satisfies the necessary product’s structural and functional requirements by simultaneously designing the product and all of its connected operations in a production system.

- 3. Manufacturing consequences are also linked to concurrent engineering.

- 4. An early product launch is made possible through concurrent engineering. The lead time for production is shortened.

- 5. It also controls parallel processing to cut down on waste and delay.

- 6. The entire development process involves all of the professionals from the relevant areas, such as design, production, and marketing.

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Industrial Engineering Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Industrial Engineering Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One VIew) | Student Result |