Aktu Btech Quantum Notes will improve your ability to pass the Geotechnical Engineering exam. Your path to success is through these crucial, in-depth resources and frequently asked questions. Today, improve your learning! Unit-3 Soil Compaction and Consolidation

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Geotechnical Engineering: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 3rd Year * Aktu Solved Question Paper

Q1. What is compaction ? What kind of improvement of the engineering properties of a soil mass can be brought about through compaction ?

Ans. A. Compaction: It refers to mechanically compressing the soil granules together. The void space in the soil mass is evacuated of air during compaction.

B. Effects of Compaction on Engineering Properties of Soil: Following are the engineering properties affected by the compaction of soil.

- 1. Permeability: The permeability is reduced as a result of compaction. With the same dry density of fine-grained soil, it has been discovered that compacted wet soil will be less permeable than compacted dry soil.

- 2. Compressibility: It has been discovered that for soil samples that were initially saturated and had the same void ratio, a wet side compacted soil is more compressible than a dry side compacted soil in low pressure ranges, and vice versa in high pressure ranges.

- 3. Pore Pressure:

- i. It was discovered during an undrained shear test on saturated clay samples that smaller pore pressures form at low stresses when the sample is compacted dry of optimal, as opposed to the case when the sample is compacted wet of optimal.

- ii. Yet, with the same density and water content, at high strains, the development of pore pressure is the same in both types of samples.

- 4. Stress-Strain Relation: Whereas samples compacted wet of optimum, with the same density, create significantly flatter stress-strain curves with an increase in stress even at high strains, samples compacted dry of optimum produce much steeper stress-strain curves with peaks at low strains.

- 5. Shrinkage and Swelling:

- i. A soil compacted dry of optimal density shrinks noticeably less than one compacted wet of optimal density at the same density.

- ii. Moreover, compared to samples of the same density compacted wet of optimum, the soil compacted dry of optimum demonstrates stronger swelling characteristics.

Q2. Explain the field methods for compaction of soil in details.

Ans. Method of Compaction: The three methods of compaction used in practice are ramming, rolling and vibrations.

A. Ramming:

- 1. Tampers are utilized in this process of soil compaction.

- 2. A hand-operated tamper, also known as a rammer, is made out of a 3–5 kg block of stone or iron that is fastened to a wooden rod. The tamper is raised approximately 0.30 metres before being lowered upon the dirt.

- 3. Compressed air or petrol power can be used to drive a mechanical rammer. From 30 to 150 kg heavier, it is substantially heavier. In rare unique circumstances, mechanical rammers up to a mass of 1000 kg have been used.

- 4. If alternative methods of compaction are impractical, tampers are used to compact soils next to existing structures or in restricted spaces, such as trenches and below bridge abutments.

- 5. Tampers are not cost-effective when working with huge amounts of dirt due to their extremely low output. For all kinds of soil, tampers are useful.

B. Rolling: Rolling of soil is done by various types of rollers.

1. Smooth Wheel Roller:

- i. A smooth-wheel roller typically has three wheels: one small wheel up front, two large wheels at the back.

- ii. There are just two drums in a tandem type smooth-wheel roller one in the back and one in front.

- iii. A smooth-wheel roller’s mass typically ranges from 2 to 15 Mg.

- iv. Compaction is accomplished in these sorts of rollers by applying pressure to the soil mass.

- v. These are generally suitable for crushed stones, gravel and sand (coarse grained soil).

- vi. This is generally used for road construction.

2. Sheep Foot Roller:

- i. This style of roller is made of a steel drum and several round and rectangular projections or feet.

- ii. A foot measures 50 to 100 cm. 150 to 250 mm of protrusion from the drum surface and a 2 surface area.

- iii. Depending on the size of the drum and whether it is partially or completely filled with water or sand, the very high contact pressure, which ranges from 1400 to 7000 kPa, is present since the covering is between 8 and 12%.

- iv. This kind of roller compaction is accomplished by kneading, which creates a somewhat stronger link between the soil mass’s compacting layers.

- v. These are generally used for the construction of core of earthen dam (cohesive soils such as clay and silt).

3. Pneumatic Tyred Roller:

- i. This kind of roller is made up of two axles and a box or platform set between them. There is one extra wheel on the rear axle than the front.

- ii. This roller has roughly 80% coverage, meaning that tyres cover 80% of the surface area.

- iii. The tyre pressure in small rollers is around 250 kPa, however it can range from 400 to 1050 kPa in bigger rollers.

- iv. The soils are typically compacted with 8 to 10 passes from the rollers in layers that are around 200 mm thick.

- v. In these rollers, compaction is accomplished by applying pressure and kneading motion at the same time.

- vi. Although they can be used with any type of soil, they are typically applied on cohesive soils.

- vii. These are used for construction of air fields, roadways and earthen dams.

C. Vibrations:

- 1. Vibratory compactors carry out the task. Vibrations are created in the soil during compaction in vibratory compactors.

- 2. A range of compactor configurations are available. A vibratory roller is a vibrator that is installed on a drum. Both the smooth-wheel type and the pneumatic variant of these rollers are offered.

- 3. In a smooth-wheel type, an arrangement of eccentric weights is driven by a separate engine to oscillate the drum at high frequency but with low amplitude. These rollers work well for compacting layers up to 1 m thick of granular soils without fines.

- 4. A separate vibrating device is attached to the wheel axle in a vibratory compactor with pneumatic tyres. To prevent vibration, the ballast box is suspended from the axle independently. These compactors work well for compacting granular soils that are around 30 cm thick.

- 5. A vibrating-plate compactor is still another type of vibratory machine. There are several little plates in this system, and each plate is controlled by a different vibrating unit. There are also manual vibrating plates available. The vibrating plates’ impact is only felt at shallow depths.

- 6. The primary application is the compacting of granular foundation courses for runways and highways with thin layer thicknesses.

- 7. Vibratory compactors can compact the granular soils to a very high maximum dry density.

Q3. Let us suppose as a geotechnical expert, you have a challenge to control the compaction in a site; so how will you control the compaction by the Proctor’s needle method ?

Ans. A. Field Control of Compaction:

- 1. The field compaction control consists of the determination of:

- i. The water content at which the soil has been compacted, and

- ii. The dry density (or dry unit weight) achieved.

- 2. Periodic assessments of moisture content and dry density will be necessary throughout the compaction process in order to achieve the optimum density.

B. Methods: The methods for determining moisture content and dry density in the field, several methods are available:

- 1. Proctor needle method.

- 2. Core-cutter method.

- 3. Sand replacement method.

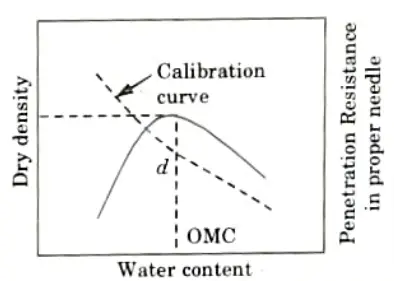

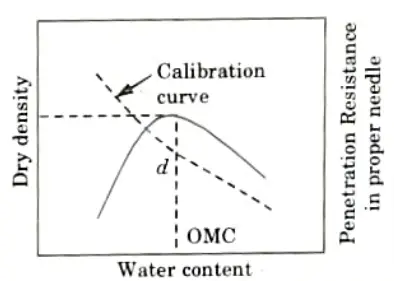

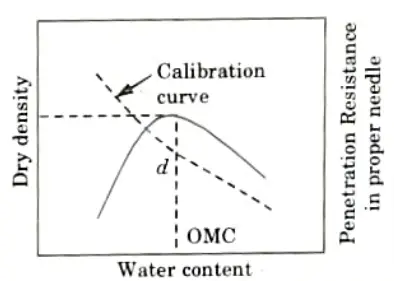

1. Proctor Needle Method:

- i. Used to quickly determine in-situ moisture contents.

- ii. The apparatus consists of a spring-loaded plunger with an attached needle that is calibrated to read penetration resistance in kg/cm2.

- iii. The needle may have a suitable region for the soil to bear on (larger bearing area for cohesive soils).

- iv. Samples are compacted in a mould in the lab, and Proctor needles are used to test penetration resistance.

- v. Dry density and water content are discovered.

- vi. On the same sample, the aforementioned procedure is performed with different moisture contents.

- vii. A calibration curve for a laboratory is therefore created.

- viii. A sample of wet soil is compacted into the mould to determine the site’s moisture content, and the Proctor needle’s penetration resistance is measured.

- ix. Moisture content corresponding to the penetration resistance obtained from the laboratory calibration curve.

Q4. What do you mean by compressibility of soil ?

Ans.

- 1. The soil’s compressibility refers to the property that causes a reduction in volume when subjected to compression pressures.

- 2. Like all other materials, the volume of the soil mass reduces when it is compressed.

- 3. The compression of soils can occur due to one or more of the following reasons:

- i. Compression of solid particles and water in the voids.

- ii. Compression and expulsion of air in the voids.

- iii. Expulsion of water in voids.

- 4. Under a vibratory load, soil can also be compressed by the evacuation of air from the voids; this process is typically referred to as compaction.

- 5. When water is ejected out of the spaces in a saturated soil mass, which has its voids filled with incompressible water, a decrease in volume or compression may occur. Consolidation is the phrase used to describe a compression like this one brought on by a sustained static strain and the subsequent pore water escape.

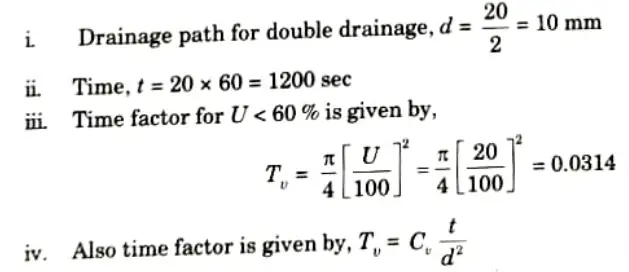

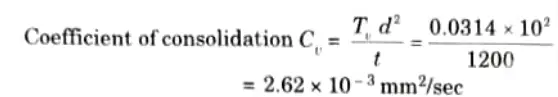

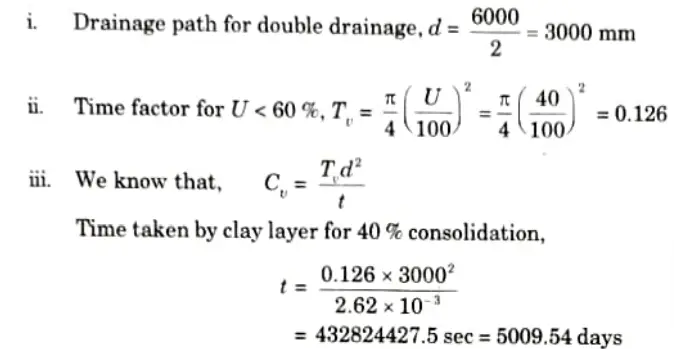

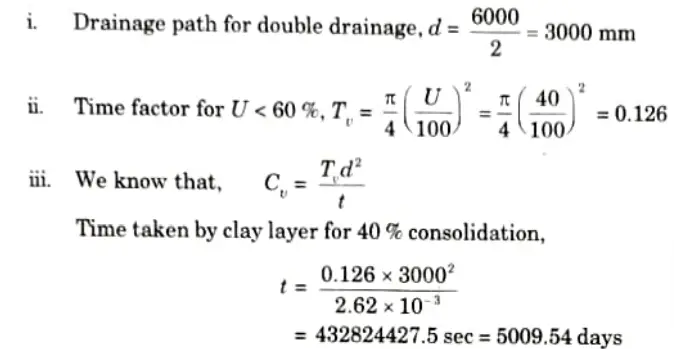

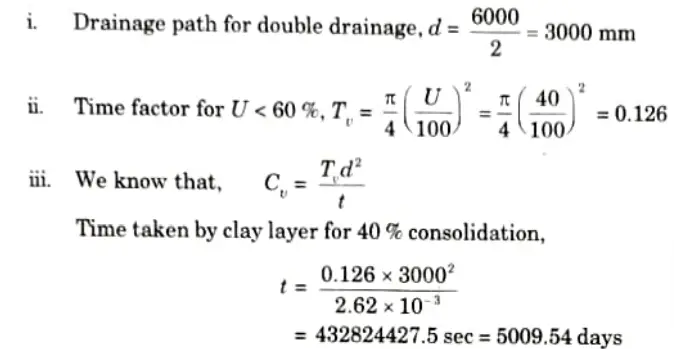

Q5. A soil sample 20 mm thick takes 20 min. to reach 20 % consolidation. Find the time taken for a clay layer 6 m thick to reach 40 consolidation. Assume double drainage in both cases.

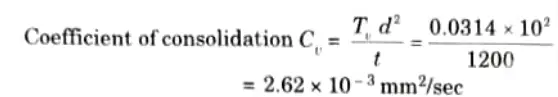

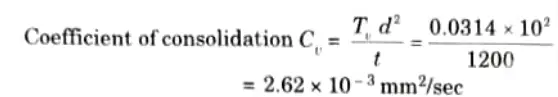

Ans. 1. For Soil Sample:

2. For Field Clay Layer:

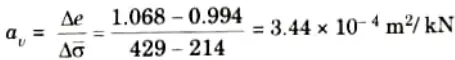

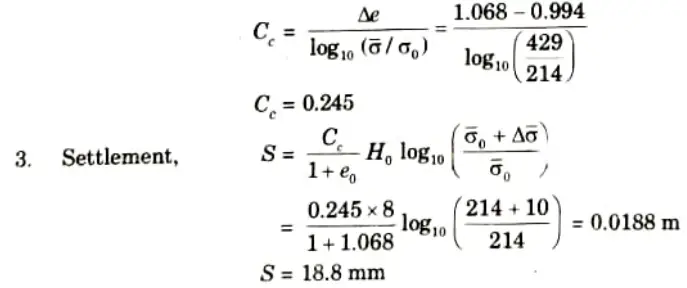

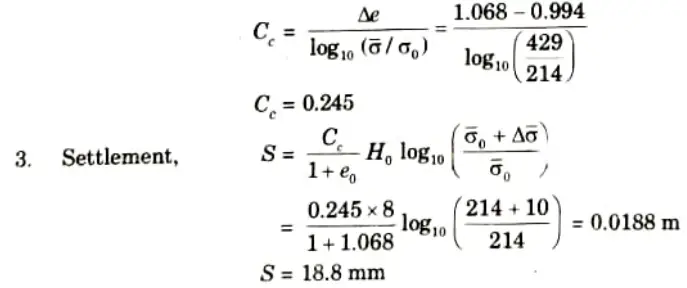

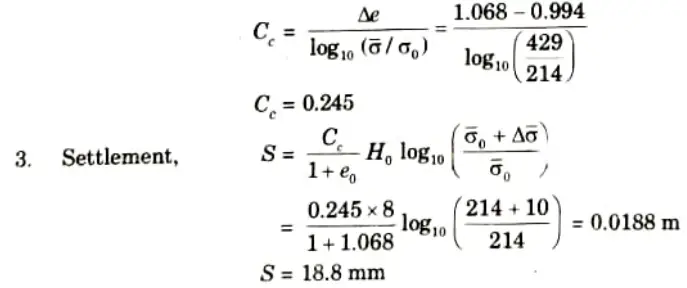

Q6. In a consolidation test, the void ratio of the specimen which was 1.068 under the effective pressure of 214 kN/m2, changed to 0.994 when the pressure was increased to 429 kN/m2. Calculate the coefficient of permeability, compression index. Also find the settlement of foundation resting on above type of clay, if thickness of layer is 8 m and the increase in pressure is 10 kN/m2.

Ans. Given: Initial void ratio = 1.068, Final void ratio = 0.994,

Initial effective pressure = 214 kN/m2,

Final effective pressure = 429 kN/m2,

Thickness of clay layer = 8 m, Increase in pressure = 10 kN/m2

To Find: Coefficient of permeability, Compression index and Settlement.

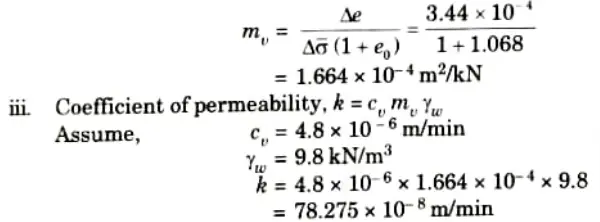

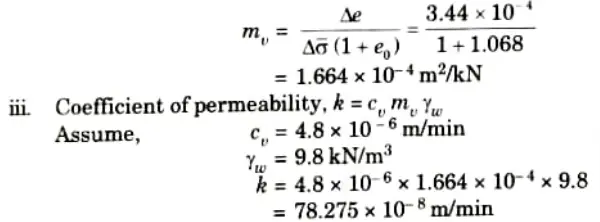

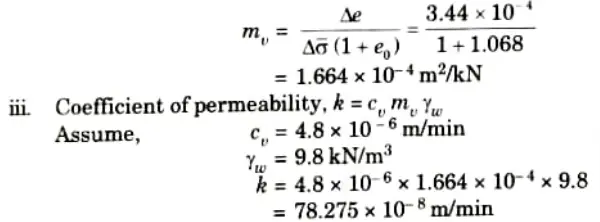

1. Coefficient of Permeability:

i. Coefficient of compressibility,

ii. Coefficient of volume compressibility,

2. Compression index,

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Geotechnical Engineering Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Geotechnical Engineering Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One VIew) | Student Result |