Study the B.Tech AKTU Quantum Book Short Question Notes on Design of Steel Structures. Dive into the world of resilient steel constructions structural engineering, analysis, and design.

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Design of Steel Structures: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 4th Year * Aktu Solved Question Paper

Unit-I: Introduction to Steel Structure (Short Question)

Q1. Write any four advantages of steel as a structural material.

Ans. Following are the advantages of steel as a construction material:

- i. It has high strength per unit mass.

- ii. It has assured quality and high durability.

- iii. If necessary, the steel framework can be strengthened at a later date. It only requires extra welding portions.

- iv. Material is reversible.

Q2. List the disadvantages of steel as a structural material.

Ans. Following are the disadvantages of steel as a structural material:

- i. It is susceptible to corrosion.

- ii. Maintenance cost is high, since it needs painting to prevent corrosion.

- iii. Steel members are costly.

Q3. Explain the mechanical properties of structural steel.

Ans. Some of the mechanical properties of structural steel are as follows :

- i. Modulus of elasticity (E) =2 x 105 N/mm²

- ii. Shear modulus (G) = 0.769 x 105 N/mm²

- iii. Poisson’s ratio (μ):

- a. In elastic range is 0.3.

- b. In plastic range is 0.5.

- iv. Coefficient of thermal expansion (𝛂) = 12 x 10-6/°C

- v. Density (ρ) =7.85 x 103 kg/m3

Q4. What are the various types of rolled steel sections found in the market ?

Ans. The following types of rolled steel shapes are generally found:

- i. Rolled steel I-section.

- ii. Rolled steel channel section.

- iii. Rolled steel angle section.

- iv. Rolled steel T-section.

- v. Rolled steel tube section.

- vi. Rolled steel bars, etc.

Q5. List the various loads which are considered in designing of steel structure.

Ans. Various loads expected to act on a structure may be classified as given below:

- i. Dead load.

- ii. Imposed load.

- iii. Wind load.

- iv. Earthquake load.

- v. Erection load.

- vi. Accidental load.

- vii. Secondary effects.

Q6. Write down the design philosophies of the steel structure.

Ans. Following are the design philosophies of the steel structure:

- i. Working stress design method.

- ii. Plastic method of design.

- iii. Limit state method.

Q7. Explain the limitations of the working stress design (WSD) approach.

Ans. Following the limitations of designing the structure by WSD approach are as follows :

- i. The structure’s failure mode cannot be visualized.

- ii. Many sources of loading change over time.

- iii. Reserve strength above the elastic limit is not qualified or used.

Q8. What are the advantages of limit state design (LSD) method ?

Ans. Following are the advantages of LSD approach:

- i. This design method acknowledges that the design parameters are variants with no unique values.

- ii. The LSD approach seeks to deal with variance in loads and member behaviour under given loads logically.

- iii. Rather of a single FOS and load factor, variability in LSD is expressed in both loading and material strength.

Q9. What are the advantages of WSM?

Ans. The advantages of WSM are as follows :

- i. This method is simple.

- ii. This is reasonable reliable.

- iii. As working stress is low, the serviceability requirements are satisfied automatically.

Q10. Define the term ‘limit state’.

Ans. Limit states are those in which the structure’s performance requirements are no longer stated. The various limit states to be considered in design may be grouped into the following major categories:

- i. Limit state of strength.

- ii. Limit state of serviceability.

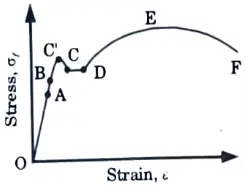

Q11. Draw the stress strain curve for mild steel.

Ans. Stress strain curve for mild steel is given below:

Q12. Distinguish between : factor of safety and partial safety factor.

Ans. Factor of Safety: It is the ratio of yield stress to permissible stress.

Partial Safety Factor: It is the ratio of characteristics strength to design strength of material.

Q13. Write down the expression for design wind speed.

OR

The design wind speed for any site is vz = vb k1 k2 k3 the factor k1is….

Ans. Expression for design wind speed is given by,

vz = vb k1 k2 k3

where,

vz = Design wind speed at any height in m/sec.

k1 = Probability factor or risk coefficient.

k2 = Terrain, height and structure size factor.

k3 = Topography factor.

Q14. Give the expression for design wind pressure.

Ans. Design wind pressure, Pz =0.6 vz2

Q15. Describe limit state of serviceability.

Ans. Following are the limit state of serviceability:

- i. Vibration in structure or any part of its component limiting its functional effectiveness.

- ii. Repairable damage or crack due to fatigue.

- iii. Corrosion.

- iv. Fire.

Q16. What are the advantages and disadvantages of ultimate load design method (ULD)?

Ans. Advantages of ULD method:

- i. Redistribution of internal forces is accounted.

- ii. It allows varied selection of load factors.

Disadvantage of ULD method:

- i. It does not guarantee serviceability performance.

Q17. What are the basic requirements that govern the design of a structure ?

Ans. Following are the basic requirement of structural design :

- i. It should have adequate strength.

- ii. It should have adequate stability and rigidity.

- iii. It should be durable and economical.

- iv. It should not interfere with the functional requirement.

Q18. What is probabilistic basis for limit state design method ?

Ans. Statistical methods have mostly been utilized in limit state design to determine loads and material parameters with a low chance of the structure reaching the limit states of strength and serviceability.

Q19. The most suitable section for the member subjected to torsional forces is…..

Ans. Hollow section.

Q20. The gauge length of the steel of equal to…..

Ans. Gauge length of the steel is equal to 5.65 √A0

Q21. Ultimate tensile strength for Fe 410 is…..

Ans. 410 MPa

Q22. The yield strength for mild steel specimen was found to be 250 N/mm². Taking factor of safety of 3, find out the working stress.

Ans. Given: fy = 250 N/mm2, FOS = 3

To Find: Working stress.

Working stress = fy/ FOS = 250/3 = 83.33 N/mm2

Q23. The design wind speed is 10 m/s. The design wind pressure will be equal to……

Ans. Given: Design wind speed, vz = 10 m/s

To Find: Design wind pressure.

Wind pressure, Pz = 0.6 vz² = 0.6 x 102 = 60 N/m²

Unit-II: Bolted and Welded Connections (Short Question)

Q1. Classify the connections in steel structures.

Ans. Following are the various types of connections:

- i. Riveted connection.

- ii. Bolted connection.

- iii. Welded connection.

Q2. What is riveting ?

Ans. Riveting is a method of connecting metal parts by putting ductile metal pins called rivets into holes in the metal pieces to be connected and producing a head at the end of the rivet to prevent each metal piece from coming out.

Q3. Give the disadvantages of riveting.

Ans. Riveting has the following disadvantages:

- i. It is associated with high level of noise pollution.

- ii. It needs heating the rivet to red hot.

- iii. Inspection of connection is a skilled work.

- iv. Removing poorly installed rivets is costly.

Q4. Give the advantages of riveted joints.

Ans. Advantages of riveted joints are as follows:

- i. Cheaper fabrication cost.

- ii. Low maintenance cost.

- iii. Dissimilar metals can also be joined even non-metallic joints are possible with riveted paths.

Q5. What is bolt and classify them ?

Ans. A bolt is a metal pin with a head on one end and a shank threaded on the other to accept a nut.

Bolts are classified as:

- i. Unfinished (Black) bolts.

- ii. Finished (Turned) bolts.

- iii. High strength friction grip (HSFG) bolts.

Q6. Define high tension bolts.

Ans. High tension bolts are bolts composed of high strength steel and tightened to a specified high tension.

Q7. Give the disadvantages of black bolted connection.

Ans. Following disadvantages of black bolted connection :

- i. Tensile strength is significantly lowered due to stress concentrations and thread root area reduction.

- ii. Joint rigidity is diminished as a result of loose fit, resulting in excessive deflections.

- iii. Vibrations cause nuts to loosen, putting the buildings’ safety at risk.

Q8. Classify the bolted connections.

Ans. Types of joints may be grouped into the following :

- i. Lap joint.

- ii. Butt joint.

Q9. What are lap joints and butt joints ?

Ans. Lap Joints: It is the most basic sort of joint. In this case, the plates to be linked overlap.

Butt Joints: The two major plates are placed against each other in this sort of connection, and the connection is made by supplying either a single cover plate attached to the main plate or a double cover plate, one on each side connected to the main plates.

Q10. List the assumptions made in design of bearing bolts.

Ans. The following assumptions are made in the design of bearing (finished or unfinished) bolted connections:

- i. There is no friction between the plates.

- ii. The shear is uniform over the bolt’s cross-section.

- iii. The stress distribution on the plates between the bolt holes is uniform.

- iv. Direct loads are distributed evenly among bolts in a group.

- v. Bending stresses developed in bolts are ignored.

Q11. What does 4 and 6 imply for bolts of grade 4.6?

Ans. The number 4 represents 1/100th of the nominal ultimate tensile strength, and the number 6 represents the yield stress to ultimate stress ratio. Thus, the 4.6 grade bolt has an ultimate tensile strength of 400 MPa and a yield strength of 240 N/mm2.

Q12. In what conditions, the reduction factor may apply on shear capacity of bolt ?

Ans. In the following conditions, the reduction factor may apply:

- i. If the joint is too long.

- ii. If the grip length is large.

- iii. If the packing plates of thickness more than 6 mm are used.

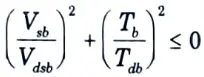

Q13. Write the interaction equation for checking the bolts for combined shear and tension.

Ans. IS: 800 – 2007 specifies the following interaction equation:

Q14. What are the advantages of butt joints over lap joints ?

Ans. Following are the advantages of butt joint over lap joint:

- 1. A bolt in a double cover butt joint has double the shear capability of a bolt in a lap joint.

- 2. Because eccentricity of forces does not occur in the case of a double cover butt joint, bending is eliminated, but it exists in the case of a lap joint.

Q15. Write down the failures of bolted joints.

Ans. These are the following failure occurs in bolted joints:

- i. Shear failure of bolts or plates.

- ii. Tension or tearing failure of plates.

- iii. Bearing failure of plates or bolt.

Q16. Classify the bolt on the basis of type of load transfer.

Ans. On the basis of load transfer, bolts are of two types:

- i. Bearing type bolts.

- ii. Friction grip type bolts.

Q17. What are prying forces ?

Ans. When bolts are used to transfer weight via direct tension, an additional force is generated in the bolts due to thin jointed plates, which is known as prying force. These forces can only occur when the ends of the connected plates come into contact as a result of an external load.

Q18. What is welded connection ?

Ans. Welding is the process of uniting two pieces of metal by forming a metallurgical bond between them. The materials to be joined are brought closer together, and metal is melted using an electric arc or an Oxyacetylene flame, as well as weld rod, which adds metal to the junction. The link between the two elements is formed after cooling.

Q19. Give the advantages of welded connection.

Ans. Following are the advantages of welded connection:

- i. Welded structures are lighter.

- ii. Noise produced in welding process is relatively less.

- iii. Welded connections have good aesthetic appearance.

- iv. Welded joints are rigid.

Q20. Write any four assumptions made in the design of welded joints.

Ans. The following assumptions are made in the analysis of welded joints:

- i. The welds that connect the various pieces are homogeneous, isotropic, and elastic.

- ii. Because the parts joined by the weld are rigid, their deformations are ignored.

- iii. Only stresses caused by external loads are taken into account. The effects of residual stress, stress concentrations, and weld form are ignored.

Q21. Classify the welded joints

Ans. Following are various types of welded joints:

- i. Butt weld.

- ii. Fillet weld.

- iii. Slot weld and plug weld.

Q22. Write the defects in welded connection

Ans. Following are the defects found in welding process:

- i. Incomplete fusion.

- ii. Incomplete penetration.

- iii. Porosity.

- iv. Slag inclusion.

- v. Undercutting.

- vi. Cracks.

Q23. In fillet welding, if the angle between the fusion faces is 101° the value of k’ is ……

Ans. 0.6

Q24. How the distortions in welded joints are minimized ?

Ans. Distortions in welded joint are minimized by following two methods:

- i. By preventing asymmetry in the fillet welding sequence.

- ii. By keeping plate symmetry when joining them around the position of a short-length butt weld.

Q25. Give the difference between welded joints and bolted joints.

Ans. Difference between welded joints and bolted joints are as follows:

- i. The welding process is faster than the bolting technique.

- ii. Welding is a silent process, whereas bolting generates a great deal of noise.

- iii. A welded joint is more efficient than a bolted joint.

- iv. When opposed to bolting, welding allows for less expensive modification.

Unit-III: Tension Members (Short Question)

Q1. Define the term ‘tension member’.

Ans. A tension member is a structural member that is subjected to two pulling forces at its ends.

Q2. List out some of the tension members used in bridges and buildings.

Ans. The various forms of tension members are as follows:

- i. Wires and cable.

- ii. Bars and rods.

- iii. Plates and flat bars.

Q3. What is net sectional area ?

OR

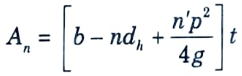

Write the expression to calculate the net area of cross section of a plate of width ‘b’ and thickness ‘t’ and having staggered holes of pitch ‘p’ and gauge ‘g’.

Ans. The net sectional area of a tension member is equal to the member’s gross sectional area less the sectional area of the maximum number of holes.

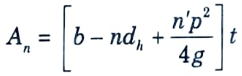

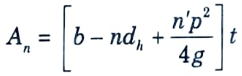

For staggered bolting, net area of cross-section,

where,

n’ = Numbers of staggered pitch.

n = Numbers of hole in the zig-zag line.

t = Thickness of plate

Q4. Write the various types of failure of tension members.

Ans. Following are the types of failure of tension member:

- i. Gross section yielding.

- ii. Due to net section rupture.

- iii. Block shear failure.

Q5. What is lug angle ?

Ans. An additional short angle may be used for the effective size of the gusset plates to reduce joint length and shear lag. The lug angle is the name given to such an angle.

Q6. What do you mean by built-up member ?

Ans. A member made by linking many elements to make a composite section that acts as a single member.

Q7. Explain block shear failure.

Ans. For specific connection arrangements and in coped beam, block shear failure is characterised by tearing off of a segment or block of material at the end of a member.

Q8. Give the IS specification for lug angle when main member is an angle ?

Ans. Following are the IS specification for lug angle:

- i. The effective section shall be taken as the entire area of the member rather than the net effective section (i.e., with a decrease for outstanding leg area). The total area of the member is the gross area less the bolt hole deduction.

- ii. The lug angle and fastener connecting the lug angle to the gusset plate should be at least 20% stronger than the force in the outstanding leg.

- iii. The fastener connecting the lug angle and the main member must be at least 40% stronger than the force carried by the outstanding leg.

Q9. Where tension members are used?

Ans. Tension members can be found in overhead tanks, cable and suspension bridges, floor decks, hinge supporting floor beams, and other structures.

Q10. Define gusset plate.

Ans. A gusset plate is a plate used to construct connections where more than one part is to be joined, such as truss joints, truss girder joints, and so on. The orientation of the members meeting at the joint usually determines the size and shape of the gusset plates. The gusset plate’s minimum thickness is 12 mm.

Unit-IV: Compression Members (Short Question)

Q1. What is compression member ?

Ans. A compression member is a straight structural member that is subjected to two equal and opposing compressive forces at its ends.

Q2. What do you understand by buckling of column ?

Ans. The compression members’ instability is marked by their deflection in their own plane.

Q3. State the possible failure modes of an axially loaded column.

Ans. Following are the failure made of an axially loaded column:

- i. Flexural buckling.

- ii. Torsional buckling.

- iii. Flexural-torsional buckling.

Q4. Define effective length of column.

Ans. It is the distance between points of contraflexure in a compressive member.

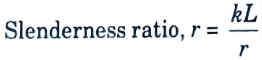

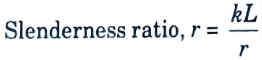

Q5. What is meant by slenderness ratio of a column ?

Ans. It is the ratio of the effective length of a column to its appropriate radius of gyration.

Q6. What do you understand by inelastic buckling ?

Ans. Inelastic buckling is a common phenomena in intermediate columns, when tangent or decreased modulus replaces elastic modulus.

Q7. What is flexural buckling ?

Ans. Flexural buckling is defined as a deflection generated by bending, or flexure, about the axis with the greatest slenderness ratio. It is also referred to as Euler buckling. Compression members of any cross-sectional configuration can fail in this manner.

Q8. What do you mean by torsional buckling ?

Ans. Torsional buckling happens when a member’s torsional stiffness is much less than its bending rigidity. Twisting about the longitudinal axis of members causes this sort of failure.

Q9. Describe the flexural-torsional buckling.

Ans. A combination of flexural and torsional buckling causes this type of failure. Members bend and twist at the same time. This form of failure can occur solely with unsymmetrical cross-sections, both with one axis of symmetry and without.

Q10. Define splice?

Ans. Connecting two pieces of section to get the required length of column is called column splice.

Q11. What is a base plate and why it is required ?

Ans. A base plate is a solid piece of material with sufficient strength and sturdiness to act as the surface on which other things are attached in order to be sustained.

A base plate used to distribute vertical loads from structural columns or machinery.

Q12. Give the classification of column bases.

Ans. Following are the types of column bases :

- i. Slab base.

- ii. Gusseted base.

Q13. Describe the term slab base.

Ans. The column in this case is directly attached to the base plate by a cleat angle. The bearing transfers the load to the base plate.

Q14. Explain the term ‘gusseted base’.

Ans. Gussets connect the column to the base plate in a gusseted base. The load is distributed to the base in part via bearings and in part via gussets.

Q15. What are the assumptions made for design of axially loaded compression member?

Ans. Following are the assumptions made for designing a compression member:

- i. The ideal column is believed to be perfectly straight with no crookedness, which is never the case in practise.

- ii. In a built-up column, the modulus of elasticity is assumed to be constant.

- iii. Secondary stress is neglected.

Q16. An electric pole of height 5.0 m is fixed at bottom. It carries a wire at top and free to move sideways. The effective length of pole is…..

Ans. Given: Height of pole, L = 5m

To Find: Effective length of pole.

Effective length of pole, leff = kL = 1.2 x 5 = 6m

Q17. What are the purposes of lacing?

Ans. Lacing serves to keep the various elements of a column straight and parallel at the proper distance apart, as well as to equalize the load distribution between them.

Q18. Where slab base plates are provided ?

Ans. These are used in those columns which carries small loads.

Q19. When we use gusset base plates ?

Ans. For column carrying heavy loads, gussets bases are used.

Unit-V: Design of Beams (Short Question)

Q1. What do you mean by beams ?

Ans. Beams are structural members that bear loads applied transverse to their longitudinal axis. These are supposed to be horizontally positioned and subjected to vertical loads.

Q2. Classify the beams.

Ans. Beams are classified as given below:

- i. Floor beam.

- ii. Girder.

- iii. Girt.

- iv. Joist.

- v. Lintel.

- vi. Purins.

- vii. Rafter, etc.

Q3. What do you mean by laterally restrained beam ?

Ans. Laterally supported beams are often referred to as laterally restrained beams. Laterally supported means that lateral deflection of a beam’s compression flange is prevented by providing effective lateral support.

Q4. Define laterally unsupported beam ? Give an example.

Ans. Any beam that bends along its primary axis and the compression flange is not restricted from buckling is laterally unsupported. These beams have the ability to tilt along the y axis. In plate girders, the effect is typically evident as lateral torsional bucking.

Example: I section beam, channel section beam, built-up section beam, etc.

Q5. Categorize the beam sections.

Ans. On the basis of width-thickness ratio, the sections are classified into four classes, these are:

- i. Plastic section.

- ii. Compact section.

- iii. Semi-compact section.

- iv. Slender section.

Q6. What is shear lag effect ?

OR

What is the concept of shear lag ?

Ans. The stress distribution over the flange as a result is non-uniform. Shear lag is the name given to this phenomena. It is determined by the width-to-span ratio, beam end constraints, and load categories.

Q7. Explain the web buckling.

Ans. When placed under concentrated load, the web of a rolled steel segment behaves like a column. Because the web is so thin, it is prone to buckling.

Q8. Describe the web crippling.

Ans. The intersection of the web and the flange causes stress concentration. As a result, significant bearing strains arise beneath the focused load. As a result, the web around the stress concentration tends to fold over the flange. This type of local buckling is known as crippling or web crimpling.

Q9. What do you understand by purlin ?

Ans. Purlins are beams that are installed over trusses to support the roofing between the trusses. These are positioned at an angle over the main rafters of the trusses.

Q10. What are the assumptions made for elastic critical moment ?

Ans. These are the following assumptions made for elastic critical moment:

- i. The beam is initially undistorted and without imperfection.

- ii. The behaviour of the beam is elastic.

- iii. The load acts in the plane of web only.

- iv. Ends of the beam are simply supported vertically and laterally.

Q11. What are the different modes of failures of beam ?

Ans. Following are the mode of failures of beam:

- i. Excessive bending causes collapse.

- ii. Lateral torsional buckling of long beams that are improperly braced in the lateral direction.

- iii. Failure owing to local buckling of a flange in compression or a web under compression due to concentrated stresses.

- iv. Local failure by (a) Shear yield of web, (b) Local crushing of web and (c) Buckling of thin flanges.

Q12. What is local buckling of a beam member ?

Ans. Local buckling is a common feature of cold formed steel sections because the very thin components utilized will always buckle before yielding.

Q13. Write down the design considerations for beam.

Ans. The following points should be considered in the design of beam:

- i. Bending moment.

- ii. Shear force.

- iii. Deflection.

- iv. Bearing stress.

- v. Buckling.

Q14. Write the different sections of plate girder.

Ans. Following are the different sections of plate girder:

- i. Bolted without cover plates.

- ii. Bolted with cover plates.

- iii. Box girder.

- iv. Girder with side plates.

- v. Welded.

- vi. Delta girder.

Q15. In a roof truss top chord members are also known as ……

Ans. Principal rafter.

Q16. Explain the effects of holes in beam,

Ans. It reduces the section modulus and bending stresses in beam.

Q17. Why an I-section commonly used as a beam member even though its lateral bucking strength is low ?

Ans. Following are the reason for used an I-section:

- i. I-sections have a larger moment of resistance because the flange area is offset from the neutral axis.

- ii. In an I-section, more material is concentrated near the outer fibres, reflecting the areas of greatest stress, and hence the beam is stronger than a rectangular cross-section beam.

Q18. What is the main purpose of a gantry girder ?

Ans. Gantry girders are used in industrial structures to support overhead cranes used for large load transportation and lifting.

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Design of Steel Structures Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Design of Steel Structures Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One View) | Student Result |