Solid Waste Management: AKTU B.Tech question paper with answers is a valuable resource that encompasses a range of exam-style questions and detailed solutions, aiding in effective preparation for solid waste management-related examinations

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Solid Waste Management: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 4th Year

Section A: Short Question In Solid Waste Management

a. List out the methods for the primary collection of waste stored at various sources of waste generation.

Ans. Wheelbarrow, Hand-cart, Cycle cart, Tractor.

b. Define landfill.

Ans. A landfill is a man-made method of disposing of solid and hazardous waste on land. The process of depositing solid waste in a landfill is referred to as landfilling. Monofills are landfills for individual waste constituents such as combustion ash, asbestos, and other similar wastes.

c. Classify the collection systems based on mode of operation.

Ans. Following are the two collection system of landfill gases:

i. Passive gas collection system.

ii. Active gas collection system.

d. Mention the two separate components for routing procedures.

Ans. Routing procedures usually consist of the following two separate components :

1. Macro-routing: Macro-routing entails dividing the total collection area into routes that are sized to represent a day’s collection for each crew.

2. Micro-routing: Micro-routing can define the specific path that each crew and collection vehicle will take each collection day based on the results of the macro-routing analysis.

e. List out the physical and chemical parameters considered for energy recovery from MSW.

Ans. Physical Parameters: Following are the physical parameters considered :

1. Size of constituents.

2. Density.

3. Moisture content.

Chemical Parameters :

1. Volatile solids.

2. Fixed carbon content.

3. Inerts.

4. Calorific value.

5. C/N ratio (Carbon/Nitrogen ratio).

6. Toxicity.

f. Define cell in landfill.

Ans. A landfill cell is a discrete volume of a hazardous waste landfill that employs a liner to isolate wastes from adjacent cells or wastes. Trenches and pits are examples of landfill cells.

g. Define pyrolysis.

Ans. Most organic substances in solid waste can be split into gaseous, liquid, and solid fractions via a combination of thermal cracking and condensation reactions when heated in closed containers in an oxygen-free atmosphere. This is referred to as pyrolysis or thermal pyrolysis.

h. Explain corrosivity.

Ans. This means having the ability to corrode, erode, or eat away. This is a chemical’s destructive, harmful, deleterious, or corrosive effect on a substance. It can also be defined as a term used to describe the rate at which a substance corrodes.

i. Classify the types of incinerators.

Ans. Types of incinerators:

1. Controlled air.

2. Excess air.

3. Rotary kiln.

j. What are the major recoverable materials present in the MSW ?

Ans. Major recoverable materials present in MSW are : aluminium, paper, glass, plastics, iron and steel, scrap tires, and used oil.

Section B : Long Questions of Solid Waste Management

a. Explain physical and chemical characteristics of solid wastes.

Ans. Physical Characteristics of Solid Waste :

1. Density :

- i. It is expressed as mass per unit volume kg/m³.

- ii. This parameter is required for designing a solid waste management program.

- iii. A reduction in volume by 75 % is achieved through normal compaction equipment, so that an initial density of 100 kg/m3 may readily be increased to 400 kg/m3.

- iv. Significant changes in the density occur as waste moves from sources to disposal site, as a result of scavenging, handling, wetting, and drying by the weather and vibration during transport.

2. Moisture Content :

- i. Values greater than 40 % are also not common.

- ii. Moisture increases the weight of solid waste, increasing the cost of collection and transportation.

- iii. As a result, waste should be protected from rain and other sources of extraneous water.

- iv. Moisture content is an important factor in determining the economic feasibility of waste incineration.

- v. During incineration, energy must be supplied for water evaporation and vapour temperature rise.

Chemical Characteristics of Solid Waste: Following are the various characteristics of solid waste:

1. Lipids :

- i. These are included in the class of fats, oils and grease.

- ii. The principal sources of lipids in the garbage are cooking oil and fats.

- iii. Because lipids have high heating values of around 38,000 kJ/kg, waste with a high lipid content is suitable for energy recovery.

- iv. Because lipids become liquids at temperatures slightly above ambient, they contribute to the liquid content of waste during decomposition.

- v. They are biodegradable, but because of their low solubility in water, the rate of biodegradation is slow.

2. Carbohydrates :

- i. These are primarily originated from the food sources rich in starch and celluloses.

- ii. These readily biodegrade into carbon dioxide, water and methane.

- iii. Carbohydrate decomposition attracts flies and rats, so it should not be exposed for an extended period of time.

3. Proteins :

- i. These are carbon, hydrogen, nitrogen, and oxygen compounds, as well as organic acids with amino groups.

- ii. They are mostly found in food and garden waste, but their partial decomposition produces amines, which emit unpleasant odours.

4. Natural Fibers :

- i. These natural products contain cellulose and lignins, which are resistant to biodegradation.

- ii. These can be found in paper, food, and yard waste. Paper is nearly 100% cellulose, cotton is over 95%, and wood products are 40-50% cellulose.

- iii. These are highly combustible products that are best incinerated.

5. Synthetic Organic Materials :

- i. In recent years, plastics have become an important component of solid waste, accounting for 1-10% of total waste.

- ii. Because they are highly resistant to biodegradation, their presence in waste is objectionable. At the moment, much emphasis is being placed on reducing this component at disposal sites.

- iii. Plastics have a high heating value, approximately 32000 kJ/kg, making them ideal for incineration.

- iv. However, when polyvinyl chloride (PVC) is burned, it emits dioxin and acid gas.

- v. The trace gases produced during the combustion of plastic have been shown to be carcinogenic.

b. Explain the different types of transfer stations.

Ans. Types of Transfer Stations: Following are the various types of transfer stations :

1. Direct Dumping Transfer Station :

- i. Waste collection trucks (packer trucks) and other vehicles can now dump directly into a transfer trailer.

- ii. Transfer trailers typically hold 100 cubic yards and can thus accommodate three to five packer loads or numerous pickup loads.

- iii. Although some of these transfer stations are not enclosed in a building, strong winds make enclosure desirable.

2. Tipping Floor Dumping Transfer Station :

- i. Like a direct dumping station, but with more space for trucks to discharge their waste on a concrete tipping floor for inspection and emergency storage.

- ii. To push the waste from the floor into the transfer trailer, a front loader with a bucket is required.

3. Pit-Dumping Station :

- i. This has a large pit into which several trucks can unload simultaneously.

- ii. Some stations have tractors in the pit to push the waste into transfer trailers.

- iii. Others have a pit with a walking floor in the bottom of the pit.

4. Compactor Station: The waste is unloaded or pushed into the hopper of a stationary compactor and then into a completely enclosed transfer trailer or roll-off container at this type of station.

5. Roll-off Box Station :

- i. This is a low-capital-cost transfer station that can serve communities of up to 1,000 people.

- ii. The major components are a 40 cubic yard steel box, an unloading ramp that slopes up to the box’s top, and a concrete pad to support the box.

- iii. The boxes can be covered with lids and hatches to reduce wind-blown litter.

- iv. To remove the box and transport it to a landfill, a truck equipped with a special hydraulic hoist is required.

6. Drop-off Box Station :

- i. Similar to a roll-off box transfer station, but with one or more six or eight cubic yard boxes.

- ii. A large packer truck can lift and empty the boxes.

- iii. Boxes are typically located on a surfaced parking lot. Normally, the boxes and hauling services are provided by a contract hauler.

c. Examine composting process of bio degradable MSW.

Ans. Composting Process :

- 1. Municipal Solid Waste (MSW) composting is a rapidly expanding solid waste management method.

- 2. Municipal solid waste (MSW) includes residential, commercial, and institutional solid waste generated within a community.

- 3. MSW composting is the process of microbiologically degrading the organic, biodegradable portion of MSW under aerobic conditions.

- 4. During the degradation process, bacteria are used to decompose and break down organic matter into water and carbon dioxide, resulting in large amounts of heat and water vapour.

- 5. When adequate oxygen and temperatures are present, the composting process achieves a high degree of volume reduction while also producing a stable end product known as compost, which can be used for mulching, soil amendment, and soil enhancement.

- 6. MSW composting, as a form of solid waste management, reduces the amount of waste that would otherwise end up in landfills.

- 7. MSW is typically composed of organic compostable materials such as food waste and paper, as well as inert, non-biodegradable materials such as plastics and glass.

- 8. The addition of non-compostable materials may cause issues with material handling during the composting process as well as the formation of a uniform, homogeneous compost.

- 9. As a result, in order to use MSW composting as a form of waste management, the composting system must be designed to remove non-compostable materials either through presorting and screening or through sifting and removal at the end of the process.

d. Examine what are the harmful effects /risks involved due to hazardous waste.

Ans. Effects of Hazardous Wastes :

- 1. Hazardous wastes have the potential to harm the environment by contaminating the air, water, and soil. Hazardous wastes can harm all life forms once they enter the environment.

- 2. Low-level DDT exposure was found to interfere with calcium deposition in the eggshells of birds of prey, causing them to be thin and fragile and frequently crushed by the parents in the nest.

- 3. Toxic effluents from poorly managed mining operations, for example, can have devastating effects on wildlife and pose serious threats to human health.

- 4. Oil spills caused by accidents involving large ocean-going tankers have also caused significant damage to marine ecosystems and wildlife.

- 5. Hazardous wastes are defined by their proclivity to corrode, explode, burn, or cause chemical reactions.

- 6. Hazardous wastes can cause injury or even death if they cause an explosion, fire, chemical reaction, or other hazardous situation.

- 7. Hazardous wastes’ health-related properties include their proclivity to cause cancer, infections, irritations (mostly due to allergic reactions), mutations, or other toxic or radioactive effects.

- 8. Hazardous waste exposure causes health effects after hazardous components enter the body via inhalation, skin absorption, ingestion, or puncture wound.

- 9. The health effects of hazardous wastes are determined by the amount (doses), the route of exposure, and the duration of exposure.

- 10. Short-term health effects of hazardous waste exposure can include dizziness, headaches, and nausea, while long-term exposure can lead to cancer, disability, or death.

e. Explain hammer mills, flail mills and shear shredders in detail.

Ans. A. Hammer Mills :

- 1. Swinging hammerheads are attached to a rotor that rotates at high speed inside a hardened casing in a hammer mill.

- 2. A hammer mill is made up of a steel casing that houses a central shaft to which a number of swinging hammers are attached.

- 3. Rotating the shaft causes the hammers to swing out to a radial position. A screen of the desired size is fitted on the lower part of the casing and can be easily replaced depending on the particle size required.

- 4. The material is crushed and pulverized between the hammers and the casing, and it remains in the mill until it is fine enough to pass through a screen at the mill’s bottom.

- 5. Construction and working :

- i. A hammer mill is essentially a steel drum with a rotating shaft or drum on which hammers are mounted.

- ii. The hammers swing freely on the cross’s ends or are fixed to the central rotor.

- iii. The rotor inside the drum rotates at a high speed (8000-15000 rpm) while material is fed into a feed hopper.

- iv. The material is impacted by the hammer bars and expelled through screens in a predetermined size drum.

- v. Hammer mills can handle both brittle and fibrous materials; however, with fibrous materials, projecting sections on the casing may be used to provide a cutting action.

- vi. The hammer mills are available in various designs and shapes.

- vii. In pharmaceutical industry they are used for grinding dry materials, wet filter cakes, ointments and slurries.

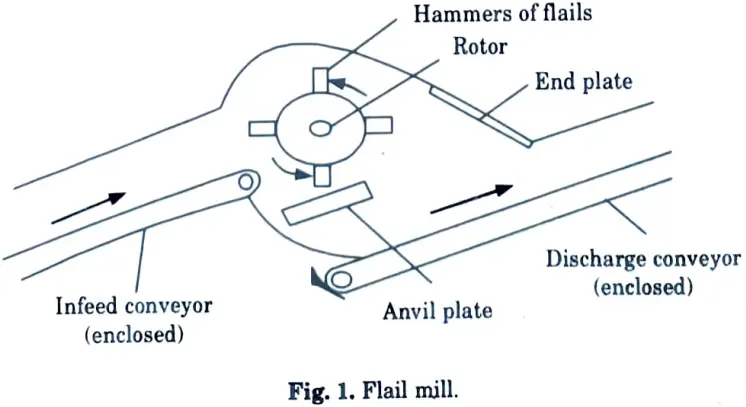

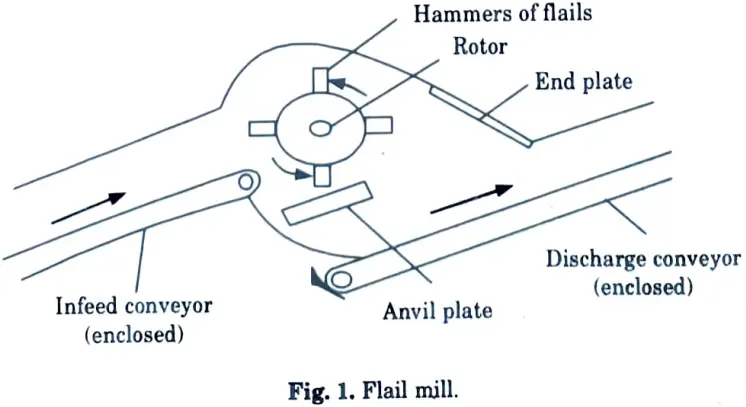

B. Flail Mill :

- 1. These machines are similar to hammer mills in appearance but they have some differences in construction and operation (Fig. 1).

- 2. Contrary to hammer mills, flail mills have no grate at the bottom and, consequently, operate as single-pass machines.

- 3. Their application is primarily for tearing bags of refuse and breaking up bundles of material; in addition to tearing, they provide some mixing of the waste materials.

- 4. These machines should be followed by shredder, as the product size is coarse.

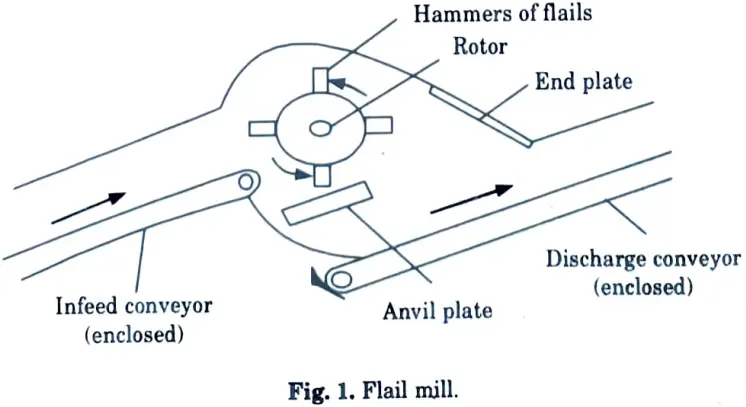

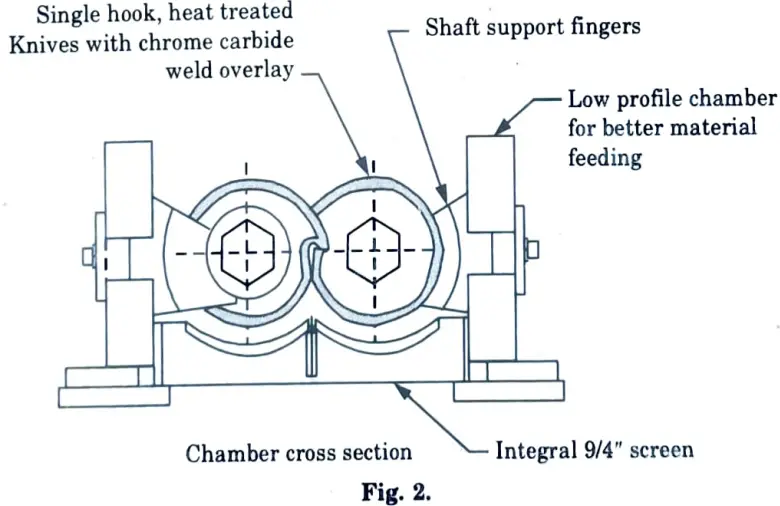

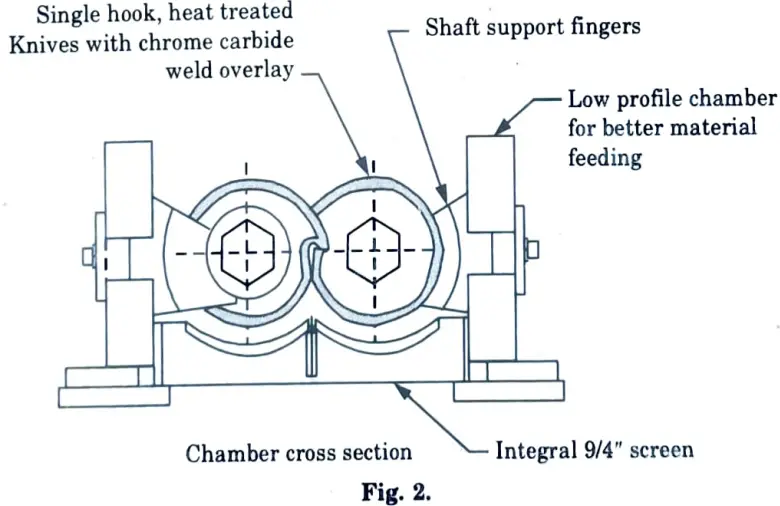

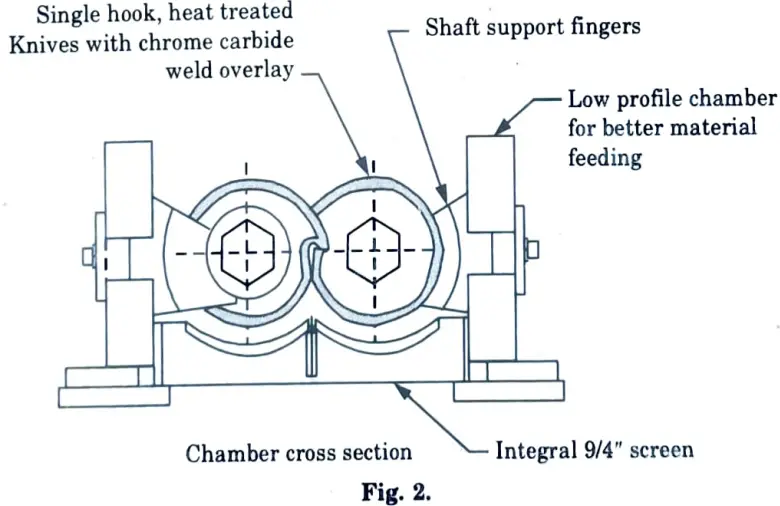

C. Rotary Shear Shredder :

- 1. Shear shredders (Fig. 2) operate like scissors during materials size reduction.

- 2. They are typically made up of two counter-rotating parallel shafts powered by hydraulic or electrical motors, as well as a series of interlocking, toothed-cutting discs mounted perpendicular to the shafts.

- 3. There are shear shredders with one, three, and four shafts available. They are single-pass machines, with the product size determined by the spacing between the cutters or the cutter and the shell in single-shaft designs.

- 4. The product size in most cases ranges between 25 and 100 mm (1-4 in). The waste material is fed between the counter-rotating shafts, and the shearing or tearing action of the cutting discs reduces its size.

- 5. In case of overload, the rotation of the shafts is automatically reversed.

- 6. The rotational speed is extremely slow, typically ranging between 50 and 200 RPM.

- 7. The low-speed hydraulic motors generate a lot of torque on the shafts, which gives the cutting discs a lot of shearing power.

- Shear shredders are effective on difficult-to-cut materials because of this power. This equipment has been used to shred materials into relatively coarse particle size (metals, truck and car tyres, wood, pallets, bulky objects, electrical and electronic devices, etc.).

- 9. On the contrary, they are incapable of shredding materials into fine particles (less than 10 mm).

Section 3 : Greenhouse Gas Production

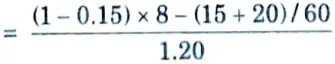

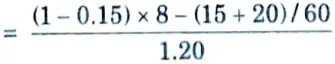

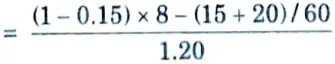

a. Solid waste from a new industrial park is to be collected in large container based on traffic studies at similar park. It is estimated that the average time to derive from garage to the first container (t1) and from the last container (t2) to the garage each day will be 15 and 20 minutes respectively. If the average time require to derive between container 6 minutes and one way distance to disposal site is 25 kms speed limit 88 km/hr. Determine the no. of containers that can be emptied per day based on 8 hrs work day. Haul constant for 88 km/hr. a and b are 0.016 and 0.011 respectively. Analyse the above hauled container collection system.

Ans. Given: Time, t1 = 15 min, Time, t2 = 20 min, Average time, dbc = 6 min, Distance, 25 km, Speed, v = 88 kmph, a = 0.016, b = 0.011, Length of working days, H = 8 hr.

To Find: Number of container.

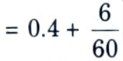

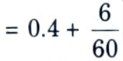

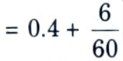

1. Pick up time per trip for hauled container,

Pbcs = pc + ac + dbc

Pick up loaded container and deposit empty container in h/trip,

pc + ac = 0.4

= 0.5 h/trip

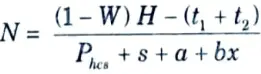

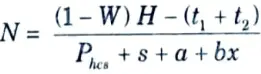

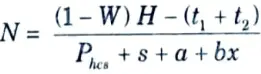

2. Time for trip hauled container system,

Thcs = Phbs + s + a+ bx

Assume single round trip hauled distance, x =2 x 25 x 50 km

Assume at site per trip, s = 0.133

= 0.5 + 0.133 + 0.016 + 0.011 x 50

= 1.2 h/trip

3. The number of trips that can be made per day,

Assume off route factor, W = 0.15

= 5.18 ⋍ 6

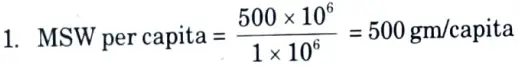

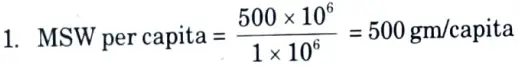

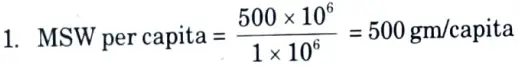

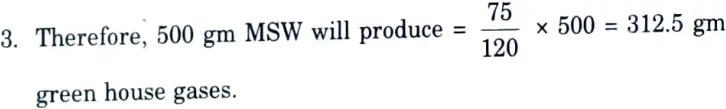

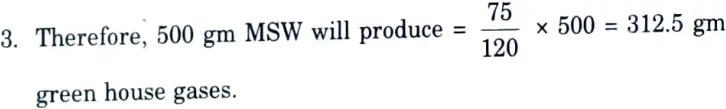

b. 50 gram of CO2 and 25 gram of CH4 are produced of decomposition of municipal solid waste with formula weight of 120 grams. Estimate the average per capita greenhouse gas production in a city of l million people with MSW production rate of 500 tonnes per day ?

Ans. Given: Population, P = 1 million, MSW production rate = 500 tonne/day, Decomposition of municipal solid waste with formula weight = 120 gm

To Find: Estimate the average per capita green house gas production.

2. 120 gm MSW produces 75 gm green house gases (50 gm CO2, 25 gm CH4)

Section 4 : Transportation of Solid Waste

a. Explain the various means used for transportation of solid waste.

Ans. A. Transportation of Solid Waste:

- 1. Solid waste transportation is an essential component of solid waste management.

- 2. Solid waste transportation is the movement of waste across a specific area by trains, tankers, trucks, barges, or other vehicles.

- 3. Wastes that can be transported include everything from municipal garbage to radioactive or hazardous waste.

B. Types of Vehicles: Following are the types of vehicles used in transportation of solid waste:

- 1. Handcarts :

- i. Fabricated of MS angle, tee and flats.

- ii. Consist 6 or 8 bins.

- iii. Each of 25 litres capacity.

- iv. It collects solid waste and transfers it to the central collection collectors.

- v. Minimum size may be 1.01 m x 0.7 m x 0.250 m.

- 2. Animal Cart :

- i. This is commonly used method to transport solid waste all around the world.

- ii. It is often pulled by donkeys.

- iii. It can carry up to 1.5 cubic metre of solid waste up to 7 km.

- iv. It can create negative impact on environment.

- v. No consumption of fossil fuels, very low capital and operational cost than motor vehicles. So, up to some extent these are economical except some other factors.

- 3. Auto Vehicles :

- i. These vehicles may be two-wheelers, three-wheelers.

- ii. This is common means of transportation in several developing countries and is a viable alternative for waste collection.

- iii. It can be fitted with a high-level tipping body of about 2 cubic meter capacity.

- iv. It is useful in cities where streets are too narrow to allow the passage of larger vehicles.

- v. But these vehicles do not operate well on rough, unpaved roads.

- 4. Tractors and Trailers :

- i. These vehicles are almost available everywhere used to transport solid waste.

- ii. These are often used as a coupled unit to collect refuse from household or storage points.

- iii. Trailers can be used as a transfer station as it can be separated from tractors easily.

- iv. These have low capital cost, capacity to transport waste is also more.

- v. A wide variety of trucks is used to transport the solid waste.

- vi. These trucks should be strong, durable, water tight and made up of stainless steel with smooth interior.

- vii. While selecting truck to transport, following points should be considered :

- a. Weight of solid waste to be transported.

- b. Weight of truck.

- c. Ease of loading and unloading.

- viii. These are inexpensive, sturdy and easily obtainable.

- 5. Dumper :

- i. These are also known as fore and aft tipper.

- ii. These are useful for handling wet refuse.

- iii. These are suitable for primary collection from main street using container relay system.

- iv. Maintenance cost of dumper is less. Hence dumpers are popular.

- v. It utilizes body capacities of about 12 cubic metre.

b. Explain the objectives and various processing techniques used for MSW disposal.

Ans. A. Objective: The primary goal of solid waste disposal is to reduce and eliminate the negative effects of waste materials on human health and the environment in order to promote economic development and a higher quality of life.

B. Techniques: Methods of MSW disposal are as follows :

- 1. Solid Waste Open Burning: Solid waste open burning is not the perfect method in the present scenario.

- 2. Sea Dumping Process: The process of sea dumping is only permitted in coastal cities. This is an extremely expensive and environmentally damaging procedure.

- 3. Solid Wastes Sanitary Landfills :

- i. The process of solid waste sanitary landfills is simple, clean, and efficient.

- ii. Layers are compressed with mechanical equipment and covered with earth, levelled, and compacted in this procedure.

- iii. A deep trench of 3 to 5 m is excavated, and microorganisms degrade organic matter.

- iv. The refuse depth in this procedure is generally limited to 2 m. Bacterial facultative hydrolysis converts complex organic matter into simpler water soluble organics.

- 4. Incineration Method :

- i. The incineration method is appropriate for combustible waste. This procedure has high operating and construction costs.

- ii. This method would be appropriate in densely populated cities where land filling sites are in short supply.

- iii. It can also be used to reduce the volume of solid waste for landfill.

- 5. Composting Process :

- i. The composting process is similar to that of sanitary landfilling and is widely used in developing countries.

- ii. This method separates and composts decomposable organic matter. Yields are stable end products that also serve as good soil conditioners.

- iii. They can be used as a base for fertilizers.

- iv. Two methods have been used in this process :

- a. Open window composting.

- b. Mechanical composting.

- 6. Disposal by Ploughing into the Fields: Ploughing into fields for disposal is not commonly used. In general, these disposals are not environmentally friendly.

- 7. Disposal by Hog Feeding :

- i. In India, hog feeding is not a common method of disposal. Garbage disposal into sewers increases BOD and TSS by 20-30%.

- ii. Refuse is ground well in grinders and then fed into sewers.

- 8. Salvaging Procedure: Materials such as metal, paper, glass, rags, certain types of plastic and so on can be salvaged, recycled, and reused.

- 9. Fermentation/Biological Digestion: Biodegradable wastes are converted to compost and recycling can be done whenever possible. Hazardous wastes can be disposed using suitable methods.

Section 5 : Important Numerical Solved Aktu

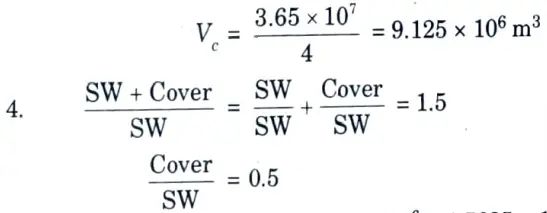

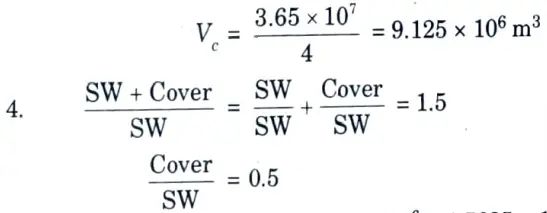

a. A landfill is to be designed to serve a population of 200000 for 25 years. The solid waste generation is 2 kg/person/day. Density of uncompacted solid waste is 100 kg/m3 and a compaction ratio of 4 is suggested. Ratio of compacted fill (Solid waste + cover) to compacted solid waste is 1.5. Determine the landfill volume.

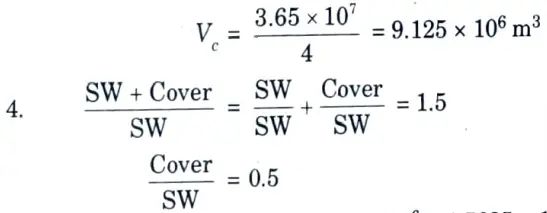

Ans. Given: Population, P = 200000, Time, T = 25 yr, Waste rate = 2 kg/person/day, Density = 100 kg/m3, Compaction ratio = 4, Ratio of compacted fill to compacted solid waste = 1.5

To Find: Landfill volume.

1. Solid waste generated per day = 2 x 200000= 400000 kg

2. Total solid waste generated in 25 yr

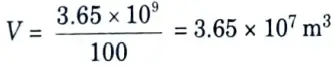

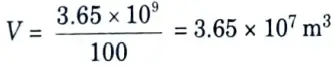

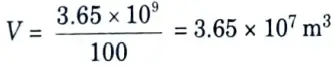

= 400000 x 365 x 25 = 3.65 x 109 kg

Volume of solid waste before compaction,

Volume of solid waste after compaction,

Cover = 0.5 x 9.125 x 106 = 4.5625 x 106 m3

5. Total volume = SW + Cover

= (9.125 + 4.5625) x 106 m3 = 13.6875 x 106 m3

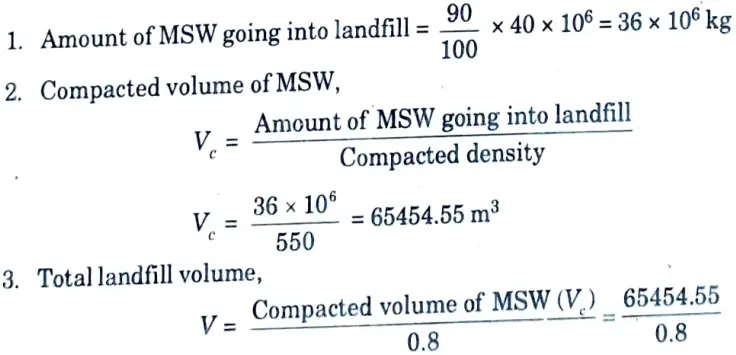

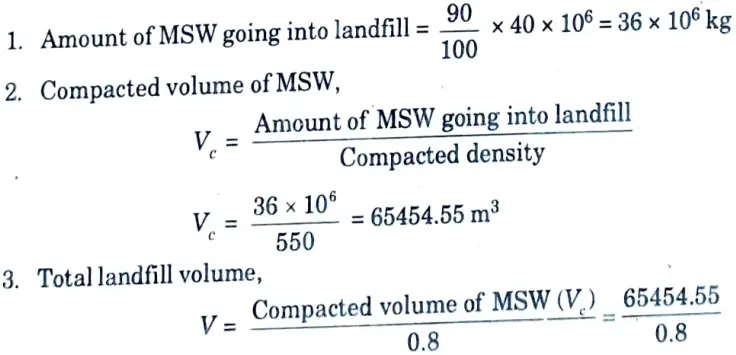

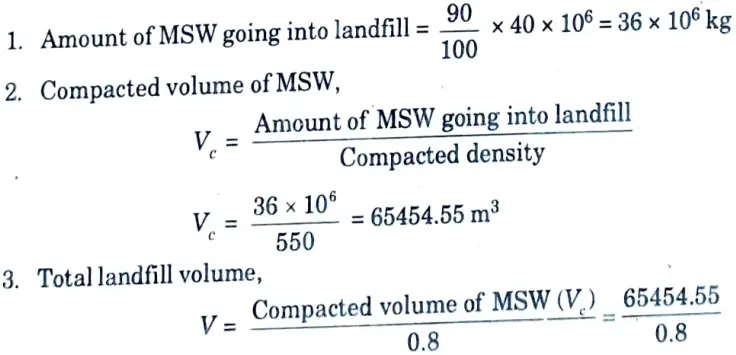

b. A city generates 40 x 106 kg of MSW per year out of which only 10 % is recyclable and rest goes to landfill. Landfill has a single lift of 3 m height and is compacted to a density of 550 kg/m3. If 80 % of landfill is assumed to be MSW, then determine the landfill area in m².

Ans. Given: Waste = 40 × 106 kg, Recyclable waste = 10 %, Landfill lift = 3 m, Density = 550 kg/m3, Landfill is assume to be MSW = 80 %.

To Find: Landfill area in m².

= 81818. 19 m3

4. Area of landfill required,

= 27272.73 m3

Section 6 : Thermal Conversion Technologies

a. List the various thermal conversion technologies. Explain each of them in detail.

Ans. The various thermal conversion technologies :

- 1. Pyrolysis :

- i. The biomass feedstock is subjected to high temperatures at low oxygen levels, thus inhibiting complete combustion, and may be carried out under pressure.

- ii. Biomass is degraded to single carbon molecules (CH4 and CO) and H2 producing a gaseous mixture called “producer gas.”

- iii. Carbon dioxide may be produced as well, but under the pyrolytic conditions of the reactor it is reduced back to CO and H2O; this water further aids the reaction.

- iv. Liquid phase products are produced when temperatures are too low to crack all of the long chain carbon molecules, resulting in the formation of tars, oils, methanol, acetone, and so on.

- v. After all of the volatiles have been removed, the residual biomass is in the form of char, which is almost pure carbon.

- 2. Carbonization :

- i. This is an age old pyrolytic process optimised for the production of charcoal.

- ii. Most of the volatile components of the wood are removed during carbonization, which is also known as “dry wood distillation.” Carbon accumulates primarily as a result of a decrease in the levels of hydrogen and oxygen in the wood.

- iii. The wood undergoes a number of physico-chemical changes as the temperature rises. Between 100 and 170°C most of the water is evaporated; between 170°C and 270°C gases develop containing condensible vapours, CO and CO2.

- iv. After cooling and scrubbing, these condensible vapours (long chain carbon molecules) combine to form pyrolysis oil, which can be used to produce chemicals or as a fuel.

- v. An exothermic reaction occurs between 270°C and 280°C, which can be detected by the spontaneous generation of heat.

- vi. The modernization of charcoal production has resulted in significant increases in production efficiencies, with large-scale industrial production in Brazil now exceeding 30%. (by weight).

- vii. There are three basic types of charcoal-making:

- a. Internally heated (by controlled combustion of the raw material),

- b. Externally heated (using fuelwood or fossil fuels),

- c. Hot circulating gas (retort or converter gas, used for the production of chemicals).

- 3. Gasification :

- i. High temperatures and a controlled environment lead to virtually all the raw material being converted to gas. This takes place in two stages.

- ii. In the first stage, the biomass is partially combusted to form producer gas and charcoal.

- iii. In the second stage, the CO2 and H2O produced in the first stage is chemically reduced by the charcoal, forming CO and H2.

- iv. The composition of the gas is 18 to 20 % H2, an equal portion of CO, 2 to 3 % CH4, 8 to 10 % CO2, and the rest nitrogen.

- v. These stages are spatially separated in the gasifier, with gasifier design very much dependant on the feedstock characteristics.

- vi. Gasification requires temperatures of about 800°C and is carried out in closed top or open top gasifiers. These gasifiers can be operated at atmospheric pressure or higher.

- vii. The energy density of the gas is generally less than 5.6 MJ/m3, which is low in comparison to natural gas at 38 MJ/m3 providing only 60 % the power rating of diesel when used in a modified diesel engine.

- 4. Catalytic Liquefaction :

- i. Catalytic liquefaction is a liquid-phase thermochemical conversion process that occurs at low temperatures and high pressures. Either a catalyst or a high hydrogen partial pressure are required.

- ii. This technology has the potential to produce higher-quality, higher-energy-density products.

- iii. These products should also require less processing to produce marketable products.

b. Explain the various design considerations for aerobic and anaerobic composting.

Ans. Aerobic Composting :

- i. Aerobic composting occurs when oxygen is present. Aerobic microorganisms degrade organic matter, producing carbon dioxide (CO2), ammonia (NH3), water, heat, and humus, a relatively stable organic end product.

- ii. Although aerobic composting produces intermediate compounds such as organic acids, aerobic microorganisms further decompose them.

- iii. Because of the relatively unstable form of organic matter in the compost, there is little risk of phyto-toxicity. The heat produced hastens the breakdown of proteins, fats, and complex carbohydrates like cellulose and hemicellulose. As a result, the processing time is reduced.

- iv. Furthermore, if the temperature is sufficiently high, this process destroys many microorganisms that are human or plant pathogens, as well as weed seeds.

- v. Although aerobic composting loses more nutrients from the materials, it is considered more efficient and useful for agricultural production than anaerobic composting.

Anaerobic Composting :

| S. No. | Item | Comment |

| 1. | Size of material shredded | Wastes that will be digested should be shredded to a size that will not obstruct the efficient operation of pumping and mixing operations. |

| 2. | Mixing equipment | To achieve optimum results and to avoid scum build-up, mechanical mixing is recommended. |

| 3. | Percentage of solid wastes mixed with sludge | Although amounts of waste varying from 50 to 90 per cent have been used, 60 per cent appears mixed with sludge to be a reasonable compromise. |

| 4. | Hydraulic and mean cell residence time 𝛉h = 𝛉c | Washout time is in the range of 3 to 4 days. Use 8 to 15 days for design or base design on result of pilot plan studies. |

| 5. | Loading rate | 0.6 to 1.6 km/(m3 days). Now well defined at present time. Significantly higher rates have been reported. |

| 6. | Temperature | Between 327 and 333 K (130 and 140° F). |

| 7. | Destruction of volatile solid wastes | Varies from about 60 to 80 per cent; 70 per cent can be used for estimating purposes. |

| 8. | Total solids destroyed | Various from 40 to 60 per cent, depending on amount of inert material present originally. |

| 9. | Gas production | 0.5 to 0.75 m³/kg of volatile solids destroyed (CH4 = 60 per cent; CO2 = 40 per cent) |

Section 7 : Disposal of Hazardous Waste

a. Discuss the various techniques used for disposal of hazardous waste.

Ans. Disposal of Hazardous Wastes :

- 1. Landfill Disposal :

- i. This is a method of burying toxic solid waste in the ground.

- ii. Hazardous waste landfills are lined with a double-layered non-porous material, such as clay, to prevent waste from leaching into the ground.

- iii. Hazardous waste is constantly dumped into this landfill, which is then covered to keep rodents and insects out. Unfortunately, this method of disposal takes up a lot of space.

- 2. Incineration :

- i. This is the process of converting your hazardous waste into an incombustible residue. It is typically used in areas where landfill space is limited.

- ii. To reduce the release of toxic gases into the atmosphere, the waste is first detoxified. Although its operating costs are high, incineration is an excellent option for waste minimization and detoxification.

- iii. Wastes containing nitrogen, phosphorous, chlorine, polychlorinated biphenyl, carcinogenic substances, and heavy metals are burned in pollution-controlling incinerators.

- 3. Dumping at Sea :

- i. A dangerous waste dump at sea. Hazardous waste is deposited in the deep sea using this method to reduce its impact on groundwater sources. Previously, waste was dumped without being treated. The idea was that the large volume of seawater would dilute the hazardous substances in the waste.

- ii. To minimise threats to marine life, hazardous waste is now treated using various methods before being dumped at sea.

- iii. To preserve water resources, environmental protection agencies around the world are currently regulating or even prohibiting this method.

- 4. Underground Disposal :

- i. Underground disposal is the best and most cost-effective option for radioactive waste. This includes waste from laboratory experiments, some medical treatments, mining of radioactive ore, and nuclear fuel production.

- ii. Underground hazardous waste disposal is only permitted in partially active and inactive mines that meet specific technical and geological requirements.

- iii. Improper hazardous waste disposal endangers your health and may result in hefty fines from your local council.

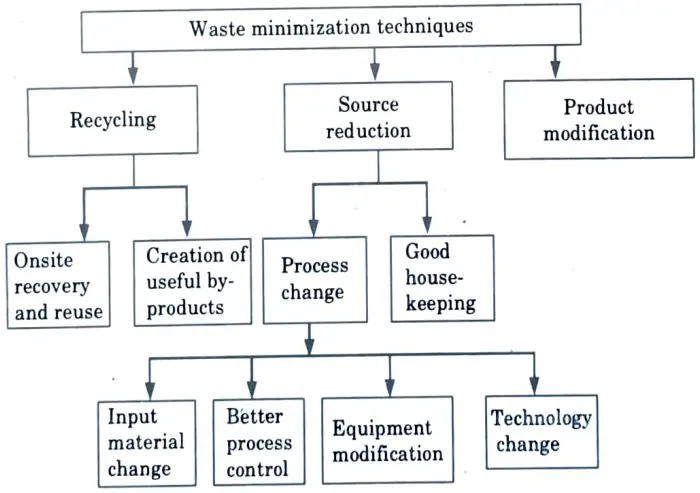

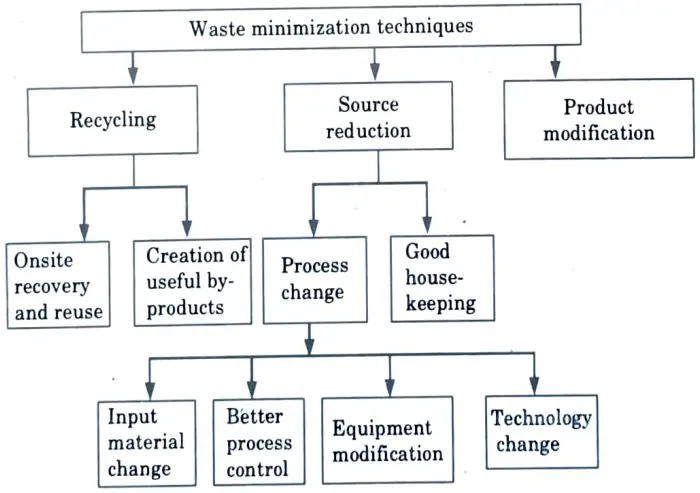

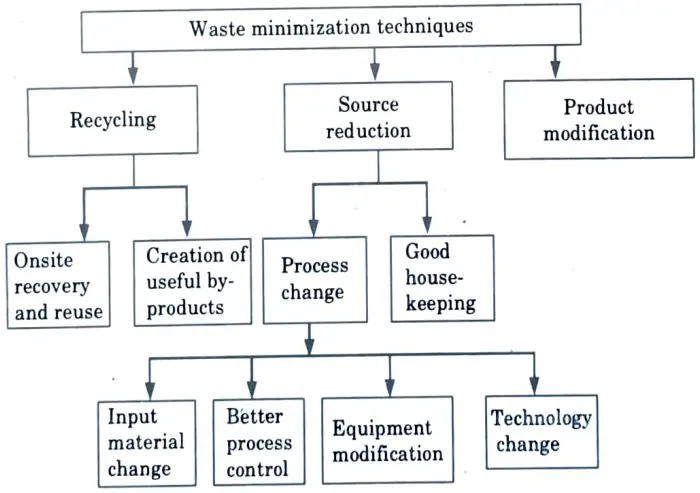

b. Discuss classification of Waste Minimization (WM) Techniques.

Ans. Classification of Waste Minimization (WM) Techniques :

A. Source Reduction :

Following are various source reduction techniques :

- 1. Good Housekeeping :

- i. Preventive maintenance schedules and routine equipment inspections to prevent leaks and spills.

- ii. Additionally, well-written work instructions, supervision, awareness, and regular workforce training would facilitate good housekeeping.

- 2. Process Change: Following are the various process change techniques :

- i. Input Material Change: Substitution of eco-friendly (nontoxic or less toxic than existing and renewable) materials with a longer service life.

- ii. Better Process Control: Modifications to working procedures, machine operating instructions, and process record keeping to increase efficiency and reduce waste generation and emissions.

- iii. Equipment Modification: Modification of existing production equipment and utilities, such as the addition of measuring and controlling devices, in order to run processes more efficiently and generate less waste and emissions.

- iv. Technology Change: Replacement of the technology, processing sequence and/or synthesis route, in order to minimize waste and emission generation during production.

- 3. Recycling :

- i. On-site Recovery and Reuse: Reuse of wasted materials in the same process or for another useful application within the industry.

- ii. Production of Useful by-product: Modification of the waste generation process so that the waste material can be reused or recycled for another application within or outside the company.

- 4. Product Modification: Product characteristics can be changed to reduce the environmental impact of production or of the product itself during or after use (disposal).

2 thoughts on “Solid Waste Management: AKTU Btech Question Paper with Answer”