Boost your Aktu Btech Power System-I prep with these frequently asked questions from Quantum Notes. Improve your understanding and perform well in your examinations! Unit-4 Equipment Management

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Quantity Estimation and Construction Management: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 3rd Year * Aktu Solved Question Paper

Q1. Define productivity. What are the different methods to measure productivity ?

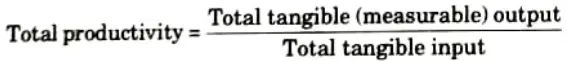

Ans. Productivity: A productivity measure is expressed as the ratio of output to input used in a production process, i.e., output per unit of input.

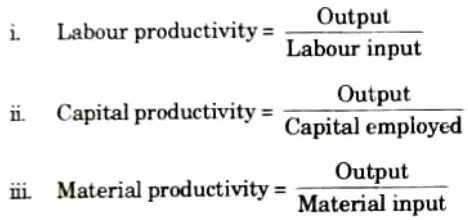

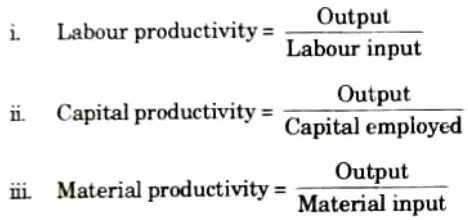

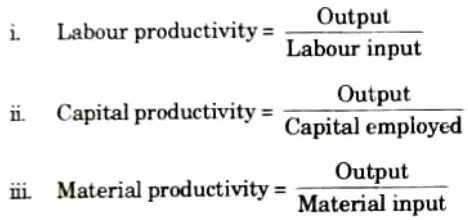

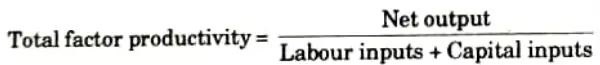

Methods: Following are the methods to measure the productivity:

- 1. Partial Productivity: It is the ratio of output to one class of input among many factors of production.

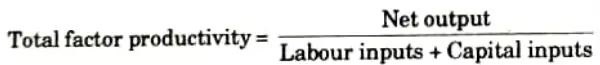

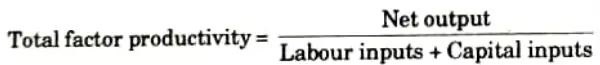

- 2. Total Factor Productivity: It is the ratio of net output to the sum of associated labour and capital (factor) inputs. Net output means output minus material, capital, energy and other input expenses.

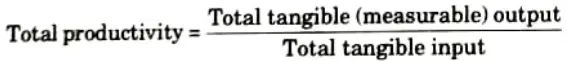

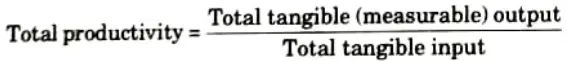

- 3. Total Productivity: It is the ratio of total output to the sum of all input factors. It represents the joint impact of all the input factors in producing the output.

Total tangible output = Value of finished product + Value of partially finished unit + Dividends from securities + Interest + Other income.

Total tangible input = Value of human, material, capital, energy and other inputs used.

Q2. How the purchase of an equipment is beneficial as compared with renting it explain.

Ans. Advantages of Owning a Construction Equipment:

- 1. When you purchase anything, you become the actual owner of it.

- 2. One of the key benefits of purchasing equipment entirely with cash is that, in comparison to renting or leasing, it may result in the lowest cost per operating hour.

- 3. The owner has total control over how the equipment is used, maintained, and replaced when it is no longer practical.

- 4. The depreciation of the equipment also has an income tax benefit.

- 5. An economically viable choice when the workload increases and the equipment is used more frequently over its useful life.

Disadvantages of Owning a Construction Equipment:

- 1. Cash purchases are the only way to purchase equipment. Cash purchases, however, can negatively impact a company’s cash flow since they lower its liquid assets, which in turn affects its working capital.

- 2. The risk of not receiving the appropriate return on the capital expenditure if the equipment is not used to its full potential.

- 3. If the equipment was purchased using financing, the equipment owner is nonetheless responsible for making the required loan payments to the lender even if the equipment is not in use.

- 4. Due to financial limitations, acquisition through purchasing may occasionally require the owner to employ outdated equipment.

Advantages of Renting a Construction Equipments:

- 1. Lower initial investment.

- 2. Access to a broader range of equipment at all times.

- 3. Latest equipment usually offered.

- 4. Maintenance, insurance etc. handled by another party.

Disadvantages of Renting a Construction Equipments:

- 1. For long-term work, the rental costs may be much more than purchasing the equipment.

- 2. Availability can also be a problem.

Q3. Explain the Use of different types of Computer Software’s in Construction Management of Large Infrastructure Projects.

Ans. Following are the software’s used in construction management:

- 1. Primavera:

- i. Primavera Systems, Inc. is the top supplier of software solutions for project, programme, and portfolio management worldwide.

- ii. It gives all kinds of enterprises the software foundation they need to manage their portfolios, programmes, projects, and resources expertly.

- iii. Primavera assists businesses in streamlining governance, prioritising project investments and resources, and producing quantifiable results that benefit the company.

- iv. Primavera offers product solutions tailored to specific industries, including manufacturing, aircraft, construction, and power.

- 2. Milestone Professional:

- i. The programme makes it quick and simple to schedule, manage, and report on projects.

- ii. It integrates with Microsoft Project and contains Gantt Chart Software for producing project management charts that are suitable for presentations.

- iii. It has the ability to manage huge projects, make reports from Microsoft Office Project, compute earned value, and distribute schedules via print, email, and the Internet. It can also create presentation reports and integrate cost and schedule.

- 3. ‘Candy’ Construction Project Modelling and Project Control:

- i. Candy combines project management and modelling for construction projects into one solution. method for project management created by industry experts exclusively for the building sector.

- ii. Components for forecasting, planning, cash flow, and evaluations can all be incorporated.

- 4. AMS Realtime Projects:

- i. This tool is strong and simple to use, offering integrated project, resource, and cost management.

- ii. It offers consolidation, aggregation, analysis, and management through strong multi-project facilities and fulfills the demands of individual project managers.

Q4. Explain the various compaction equipment used in construction industry.

Ans. Following are the various compaction equipments used in construction industry.

- 1. Smooth-Wheel Rollers:

- i. It is plain steel roller and Self-propelled type.

- ii. It has weighing from 5 to 16 tonnes.

- iii. It is used for ordinary rolling work where deep compaction is not required.

- iv. The rear wheels being usually larger in diameter and the front one being winder.

- v. Weight of rollers may be increased by filling water or sand ballast in hollow cylinder.

- vi. These rollers are effective in compacting granular soils, such as sand, gravel and crushed stone.

- 2. Sheep-foot Rollers:

- i. It is used to compact earth work in embankments and canals, among other things (where compaction deep into the layer of the earth is required).

- ii. They produce the best compaction results in soils that are primarily cohesive and impermeable, like clay.

- iii. The sheep foot rollers may weigh as much as 15 tonnes. 25 kmph is the speed at which it is moving.

- iv. The roller’s feet plough into the ground as it rolls over the surface, creating pressure and a kneading action that mix and compact the soil from the base to the top layer.

- 3. Pneumatic-tyred Rollers:

- i. It is most suitable for compacting fine-grained soil and well graded sands.

- ii. Ballasting is done using water, sand or pig iron in order to increase the self weight.

- iii. Major advantages are the ability to control the ground contact pressure by:

- a. Altering the weights of machines,

- b. Increasing the number of wheels,

- c. Increasing the tyre width, and

- d. Changing the contact area of the tyre by altering the contact pressure.

Q5. What are the methods of preparing concrete in field ? Also describe the advantages of using concrete mixer.

Ans. Following are the types of mixing used in construction site:

A. Hand Mixing: It is adopted for small works where the quantity of concrete is small. The procedure is as follows:

- 1. Depending on how much concrete needs to be mixed, a platform is built out of brick, lean concrete, or iron sheet.

- 2. The required amount of cement is poured on top of the measured amount of sand. Cement and sand are uniformly combined.

- 3. The measured amount of stone chips are then distributed evenly on top of this and stirred using shovels three times, going from the centre out to the sides and back in again.

- 4. A depression is made in the midst of the mixed pile, and half to three quarters of the necessary amount of water is put there as the materials are shovelled in the direction of the hollow. Never mix for longer than three minutes.

B. Machine Mixing:

- 1. Machine mixing is essential when producing a significant amount of concrete of the necessary quality. Better quality concrete may be made more quickly.

- 2. A concrete mixer is a piece of equipment used for this purpose; it can be batch- or continuous-type.

- i. Continuous Concrete Mixers:

- a. A continuous mixer, whose name implies that it must continually load, mix, and discharge mix until the job is finished or a work break takes place. Screw feeders load materials on a constant basis.

- b. Continuous mixtures are employed in extremely sizable undertakings like the development of high-rise buildings, bridges, and dams.

- ii. Batch Concrete Mixers:

- a. Machines known as batch mixers are frequently used to mix concrete. Batch by batch and time by time, the concrete mix produced by this mixer is collected. As a result, it is known as a batch mixer.

- b. It combines the components for a while before discharging them altogether after pouring them into a pan or drum. Until the needed quantity of concrete mix is obtained, this process is repeated.

Following are two types of batch mixers:

- 1. Drum Type Mixers: Concrete components are mixed in a drum that is actually shaped like a double conical frustum when using drum type mixers.

- 2. Pan Type Concrete Mixers: Concrete is mixed in a circular pan using pan-style mixers. Blades arranged in a star pattern inside the pan combine the ingredients.

Advantages of Concrete Mixer:

- 1. Concrete has good and quick quality.

- 2. The space is less messy and cleanup is simple because mixing is done in a machine.

- 3. Many operations can be completed without requiring the equipment to be sent back to the batch facility. You will only mix what you will pour.

- 4. Excellent when the batch plant cannot be erected at the job site or in a remote area.

- 5. By mixing only what you need, you may eliminate shortages and reduce waste from concrete production.

Q6. Explain the tunneling equipment with neat sketches.

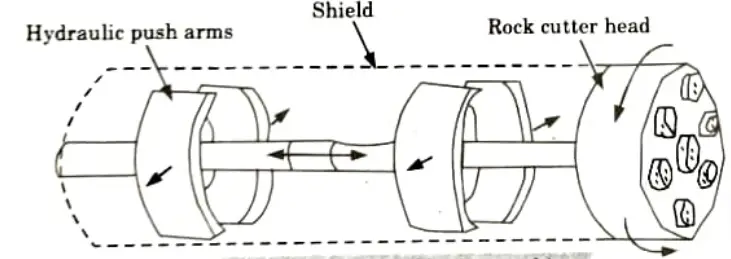

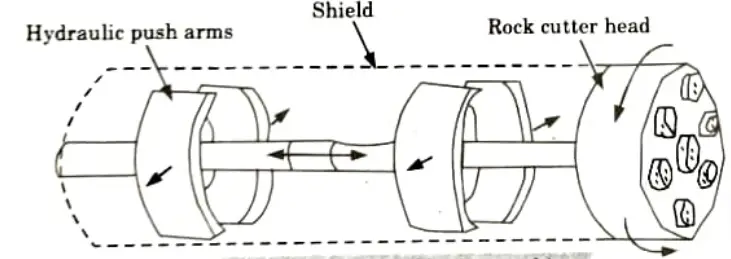

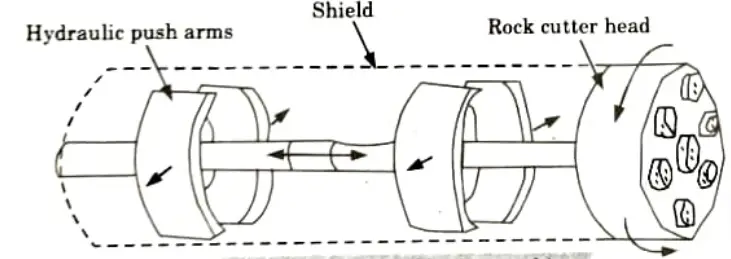

Ans. Tunneling Equipment: Following are the equipment used in tunnelling operations.

- 1. Tunnel Boring Machine:

- i. A tunnel-boring device TBMs, commonly referred to as “moles,” are tools that are used to drill circular-cross sectional tunnels through a range of rock and soil strata.

- ii. They can bore through anything from hard rock to sand.

- iii. Tunnel diameters can range from a meter (done with micro-TBMs) to 19.25 m.

- iv. Tunnels of less than a meter or so in diameter are typically done using trenchless construction methods or horizontal directional drilling rather than TBMs.

Drilling Equipments: Following are the various drilling equipments:

- 1. Drifter:

- i. A drifter is a mechanically mounted, air-operated percussion drill that is similar to a jackhammer in size.

- ii. It weighs between 45 and 68 kg and can drill holes up to 12 m deep and 11 cm in diameter.

- iii. Mines and tunnels both make great use of it.

- 2. Blast-hole Drill:

- i. It is a rotary drill made of a steel-pipe drill stem with a roller-bit at the bottom that breaks up rock as it rotates over it.

- ii. To remove the rock shavings, a steady stream of compressed air is pumped down the pipe.

- iii. While hard dolomite and limestone fall within the category of soft to medium rock, the harder igneous rock is ineligible for drilling with this drill.

- 3. Fusion Piercing Drill:

- i. At the blow pipe’s end, a mixture of oxygen and a flux-bearing fuel, such as kerosene oil, is burned to create fusion piercing.

- ii. The rock melts when the flame is pointed at it because of the high temperature (approximately 4000 °F).

- iii. The hot rock is quenched with water, creating tiny fragments that are blown out of the opening.

- iv. It is mainly used for blasting purposes.

- 4. Other drilling equipments are:

- i. Jackhammer or sinker.

- ii. Wagon drill.

- iii. Shot drill.

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Quantity Estimation and Construction Management Btech Quantum PDF, Syllabus

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Quantity Estimation and Construction Management Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One VIew) | Student Result |