Discover the world of Industrial Engineering with the B.Tech AKTU Quantum Book. Access key notes, repeated questions, and vital insights to flourish in this profession. Unit-2 Production Planning and Control

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Industrial Engineering: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 3rd Year * Aktu Solved Question Paper

Q1. Define production planning and state its objectives ?

Ans. A. Production Planning:

- 1. The selection, acquisition, and arrangement of every facility required for upcoming activities are all aspects of production planning.

- 2. Production planning refers to establishing production objectives and estimating the resources needed to carry them out.

- 3. It creates a thorough plan for attaining the manufacturing objectives quickly, affordably, and effectively.

B. Objectives of Production Planning:

- 1. Effective utilization of resources.

- 2. Steady flow of production.

- 3. Estimate the resources.

- 4. Ensures optimum inventory.

- 5. Coordinates activities of departments.

- 6. Minimize wastage of raw materials.

- 7. Improves the labour productivity.

- 8. Reduces the production costs.

Q2. Discuss the forecasting techniques.

Ans.

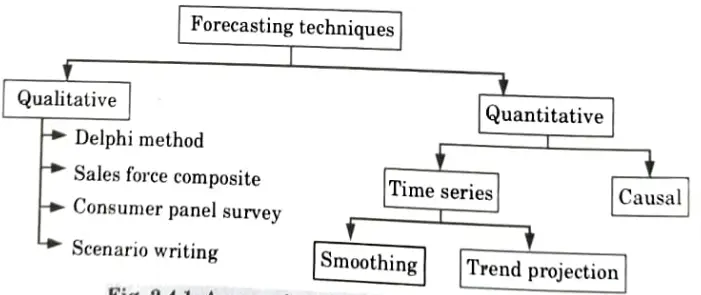

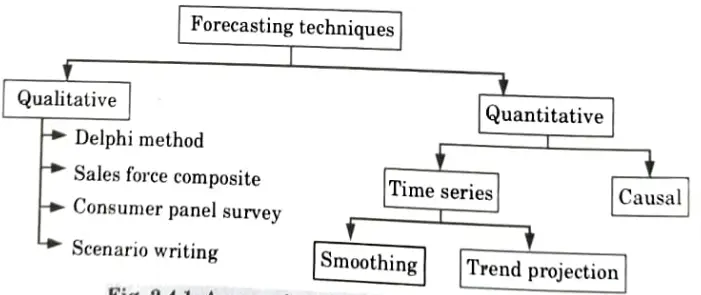

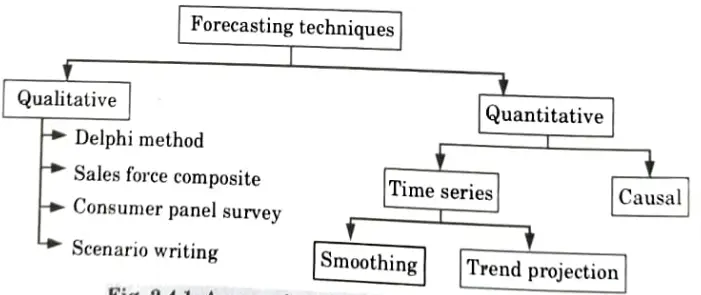

- 1. There are two types of forecasting techniques: qualitative and quantitative. The qualitative approaches, which by their very nature are subjective, rely on individual judgement and use attributes like intuition and experience as the foundation for predictions.

- 2. In contrast, quantitative approaches are objective in nature and use numerical data as the foundation for forecasting.

- 3. A forecast can be created using the time series approach or the casual method in quantitative methods.

- 4. Time series approaches use historical data to try and predict future values. The forecast is exclusively based on previous values of the variable we are trying to anticipate and/or previous forecast errors. The goal is to identify a pattern in the historical data and then extrapolate this pattern into the future.

- 5. Methods of causal forecasting are predicated on the idea that the variable we’re attempting to predict has a cause-and-effect relationship with one or more other variables.

Q3. What is correlation analysis ?

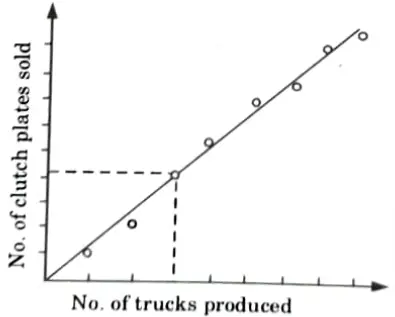

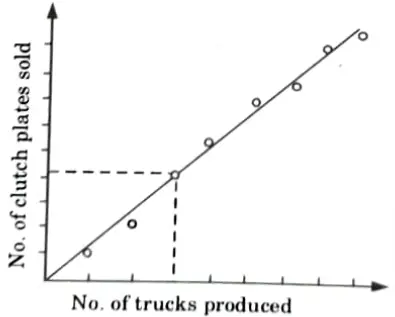

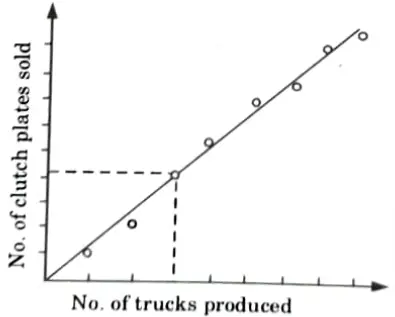

Ans. 1. This method is used when a company discovers that the sales of one of its products are strikingly associated with the sales of a key product manufactured by another company, such as the correlation between clutch plate sales and truck sales (Fig.)

- 2. In the correlation technique, the total sales for an industry (such as a company that manufactures trucks) are discovered, and the volume of sales for one’s own product (such as clutch plates) is then forecasted based on market conditions.

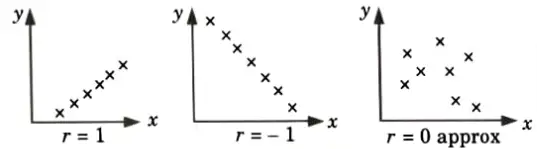

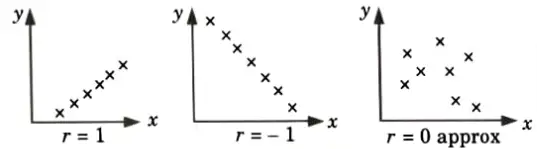

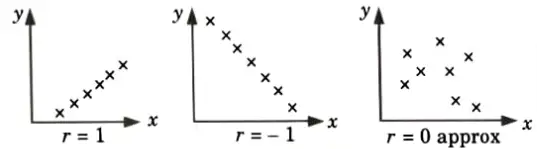

- 3. Such historical data can forecast sales estimates for the future when printed on graph paper (Fig.) with the line of best fit drawn.

- 4. A correlation coefficient measures how closely two variables (such as the number of trucks sold and the number of clutch plates sold) are related. It also shows how well one variable’s value can be predicted by another when one variable’s value is known.

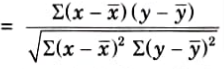

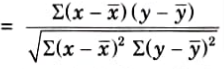

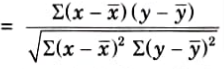

- 5. Coefficient, r for two variables x and y

Where x is the mean value of all the individual x values, and y is the mean value of all the individual y values.

- 6. The formula measures linear correlation, i.e.,

Q4. Write a short note on following :

a. Aggregate Production Planning, and

b. Master Production Schedule (MPS).

Ans. a. Aggregate Production Planning:

- 1. Aggregate planning is a high-level corporate planning activity.

- 2. Production output levels for the company’s main production lines are shown in the aggregate production plan.

- 3. The departmental strategies for sales and marketing must be integrated with the overall plan.

- 4. The aggregate production plan must take into account both current and future inventory levels of the products and their component parts because it includes products that are now being produced.

- 5. Since the marketing strategies for both existing items and newly produced products will be factored into the overall plan, it is important to compare them to the company’s total capacity resources.

b. Master Production Schedule (MPS):

- 1. The master production schedule, also known as the aggregate plan, must be created using the production numbers of the key product lines indicated in the aggregate plan (MPS).

- 2. It is a list of the goods to be produced, along with information on when and how much of each should be produced.

- 3. Products included in the MPS divide into three categories:

- i. Firm customer orders,

- ii. Forecasted demand, and

- iii. Spare parts.

- 4. Proportions in each category vary for different companies, and in some cases one or more categories are omitted.

- 5. When a consumer requests a specific product, the business is typically required to ship the item by the date that the sales departments have specified.

- 6. In the second group, production output numbers are based on sales staff estimations, statistical forecasting methods applied to historical demand trends, and other sources.

- 7. The third type comprises of repair components that will either be supplied straight to the customer or stocked at the business’ service department.

- 8. Since it must account for the lead periods to order raw materials and components, make parts in the factory, and then assemble the finished goods, the MPS is typically regarded as a medium-range plan.

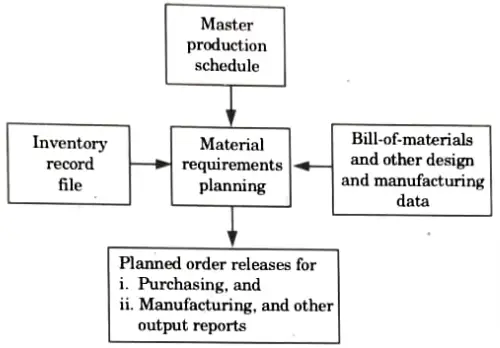

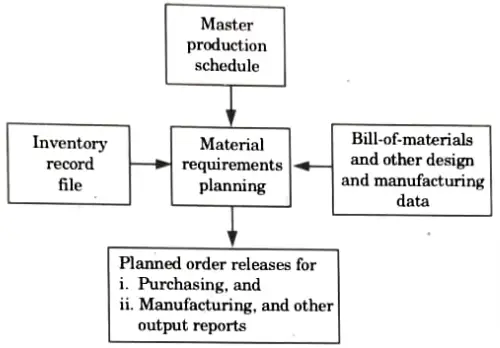

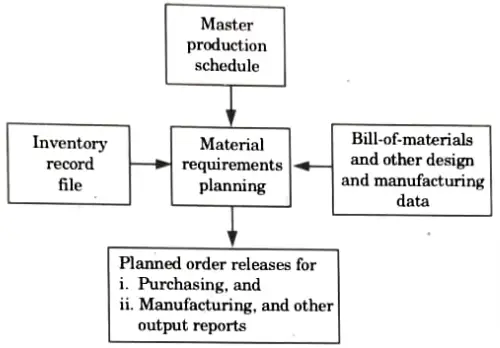

Q5. What is material requirement planning ? What are the three inputs to the MRP processor ?

Ans. A. MRP:

- 1. Material requirements planning (MRP) is a computational method that transforms the master schedule for finished goods into a specific schedule for the raw materials and components required in finished goods.

- 2. Each raw material and component item’s quantities are specified in the detailed schedule. It also specifies the ordering and delivery deadlines for each item in order to keep to the master production plan.

- 3. MRP is frequently regarded as an inventory control technique. It is a practical method for planning production and making material purchases as well as an efficient instrument for reducing wasteful inventory investment.

- 4. MRP is the best technique for figuring up how many quantities of dependant items there are.

- 5. Raw materials, work in progress (WIP), components, parts, and subassemblies make up the manufacturing inventory.

B. Inputs to the MRP Processor:

- 1. The master production schedule, data.

- 2. The bill of materials file and other engineering and manufacturing and

- 3. The inventory record file.

Q6. Describe in detail about crashing of operation.

Ans. In crashing following steps should be followed one by one:

- Step 1: Find critical path and normal project duration.

- Step 2: Find cost slope of each activity.

- Step 3: Choose the first activity that has the lowest cost slope. It should be kept in mind when crashing that it shouldn’t crash too far and put other paths in danger.

- Step 4: Choose the subsequent steeper cost slope with a crucial activity. There might be one or more key paths while performing this. The next step is to crash one activity from each path simultaneously for the same length of time.

- Step 5: Repeat the above steps unless total minimum cost and optimum duration is obtained.

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Industrial Engineering Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Industrial Engineering Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One VIew) | Student Result |