With AKTU’s Question Paper, you may embark on an Exciting Energy Conservation and Auditing Journey. Improve your understanding, test your knowledge, and fly to exam achievement.

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Energy Conservation and Auditing: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 4th Year

Section A: Short Questions In Energy Conservation and Auditing

a. Describe the significance of Bureau of Energy Efficiency (BEE).

Ans. The Bureau of Energy Efficiency’s mission is to help in the development of policies and strategies with a focus on self-regulation and market principles, within the general framework of the Energy Conservation Act of 2001, with the primary goal of reducing the Indian economy’s energy intensity.

b. What do you mean by energy conservation legislation ?

Ans.

- 1. The Indian government enacted the Energy Conservation Act, 2001, in response to the tremendous potential for energy savings and the advantages of energy efficiency.

- 2. The act establishes a legal framework, administrative arrangements, and a regulatory mechanism at the federal and state levels to launch the country’s energy efficiency programme.

c. Explain evolution of demand side management.

Ans.

- 1. The 1973 oil crisis had a significant impact on power utilities and consumers. Utilities had to deal with rising prices and fuel supply problems.

- 2. Customers were pressed by rising electricity bills and supply difficulties. Higher energy prices, as well as the challenges connected with growing energy consumption, prompted a demand for more efficient technology and services.

d. What is energy conservation planning ?

Ans. Energy conservation planning is to find out :

- i. Specifying energy conservation targets and preparing detailed plan for conservation.

- ii. Identifying the facilities which are energy inefficient.

- iii. Adoption of energy conservation measures.

- iv. Evaluation of energy conservation benefits.

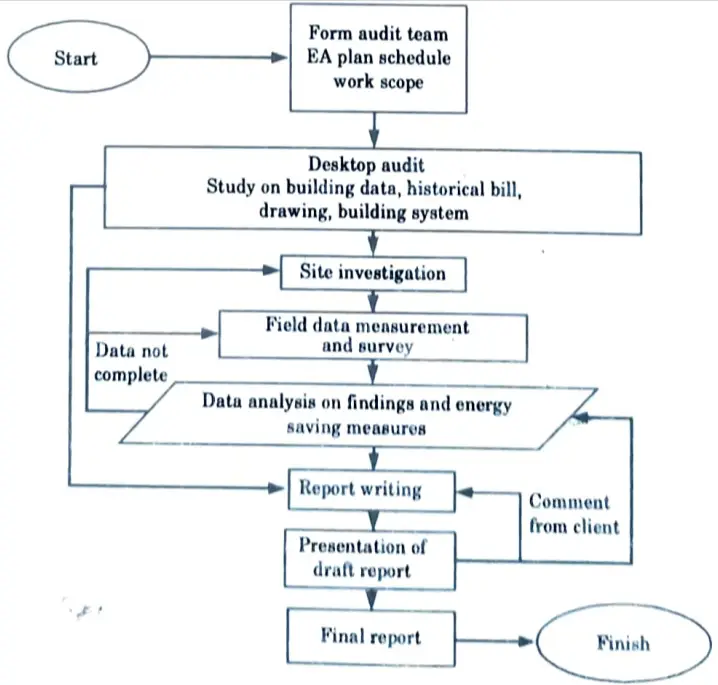

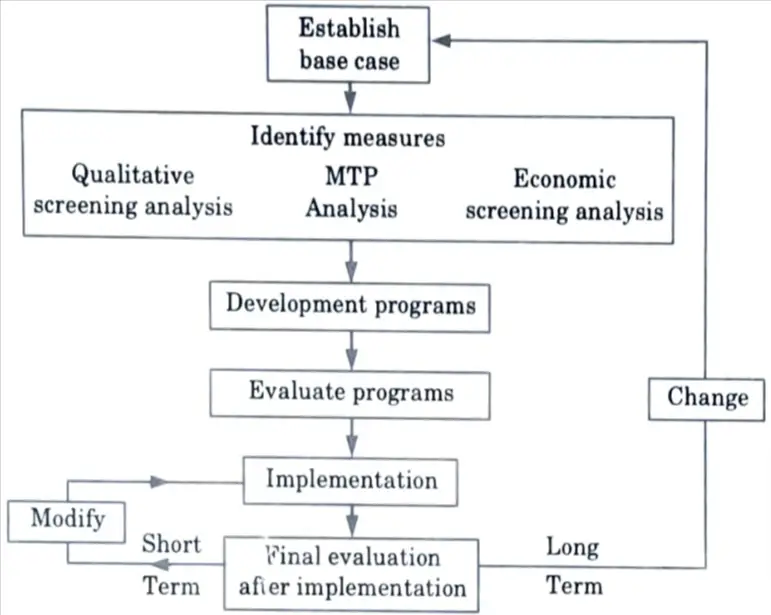

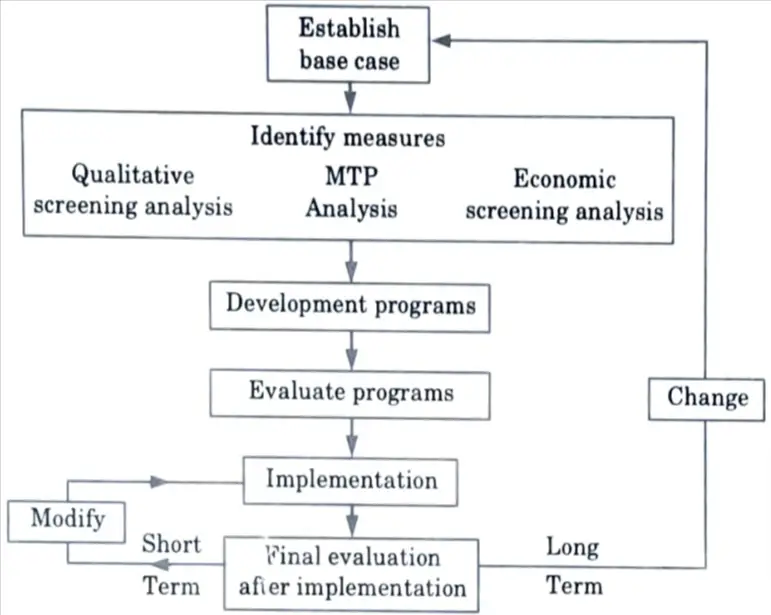

e. Draw flow chart of energy audit.

Ans. The Flowchart of energy audit process is shown in Fig.

f. List four relevant instruments to carry out energy audit.

Ans.

- a. Voltmeter and ammeter to measure voltage and current.

- b. Power factor meter to measure power factor.

- c. Power analyser

- d. Multimeter

g. Define time off day tariff.

Ans.

- 1. It is often referred to as a Time of Use (ToU) tariff. The technological advancement of metering equipment has enabled the measurement of energy consumptions at various times of day, days of the week, and seasons. Economically, ToD rates make electricity more expensive when it costs more to generate additional electricity, i.e., during peak hours, and cheaper during off-peak hours.

- 2. A tariff structure like this encourages consumers to move their load from peak to off-peak hours whenever possible, flattening the load curve.

- 3. This would benefit customers by lowering their rates, as well as the electric company, which would benefit from a drop in peak load.

- 4. It is preferable that ToD rates be made available to all consumers, albeit on a voluntary basis for residential customers and on a mandatory one for big commercial and industrial customers.

- 5. ToD electricity meters have an inbuilt timing unit.

h. What are the factors that affect the cooling rate in air conditioning ?

Ans.

- a. Temperature

- b. Humidity

- c. Purity/cleanliness

- d. Air motion.

i. What is mean by life cycle costing ?

Ans. The LCC method includes the costs of purchase, maintenance, repair, replacement, energy, and any other monetary expenditures that affect the decision factor for an investment for each of the investment possibilities.

j. What is the effect of load factor on energy conservation ?

Ans. The load factor results in a decrease or increase in peak demand and the cost of the power plant.

Section B : Important Long Questions Energy Conservation and Auditing

a. Why energy conservation is important. Explain different scheme/initiatives started by government to conserve energy.

Ans. A. Importance of energy conservation :

- 1. Energy conservation is critical to conserving nonrenewable energy resources.

- 2. Energy conservation will lower the cost of fossil fuels.

- 3. Energy saving would boost the economy by giving customers more discretionary income to spend on goods and services.

- 4. Scientific research benefits from energy conservation. This is because energy saving allows researchers to undertake more research.

- 5. Energy conservation is important for environmental protection.

B. Scheme/initiatives: The initiatives to be taken by the government for energy conservation are as follows:

- 1. To support national energy conservation and efficiency activities and programmes with leadership, policy recommendations, and direction.

- 2. To organise and present energy efficiency and conservation policies and programmes to stakeholders.

- 3. Develop methods and procedures for measuring, monitoring, and verifying energy efficiency results in specific sectors as well as at the macro level.

- 4. Leverage multilateral, bilateral, and corporate sector support for the Energy Conservation Act (ECA) and efficient energy use and conservation programmes.

- 5. To show the delivery of energy efficiency services specified under the ECA through public-private partnerships.

- 6. To interpret, develop, and manage energy conservation programmes in accordance with the provisions of the Energy Conservation Act.

- 7. To provide policy recommendations and provide direction to national energy conservation initiatives, as well as to coordinate policies and programmes on energy efficiency with shareholders.

- 8. Implement systems and procedures for verifying, measuring, and monitoring Energy Efficiency (EE) improvements.

- 9. To mobilise international, bilateral, and private-sector support for the Energy Conservation Act of 2001.

- 10. To demonstrate EE delivery systems through public-private partnerships.

b. What do you understand by national and international experiences with demand side management ? Explain in detail.

Ans. A. National experiences with DSM :

- i. Bachat Lamp Yojana :

- 1. The residential sector contributes for 25.87% of the country’s electrical demand.

- 2. The lighting load accounts for 28% of residential power demand and contributes almost entirely to peak load.

- 3. To encourage the use of energy-saving CFLs in the home sector, BEE created the “Bachat Lamp Yojana” (BLY) initiative.

- 4. Under the BLY programme, the CFL supplier would supply a maximum of four long-life, high-quality CFLs to grid-connected residential families in exchange for an equivalent number of incandescent lamps (ICL) and Rs. 15 per CFL.

- ii. Energy conservation building code and energy efficiency in existing buildings: Energy Conservation Building Code (ECBC) was created during the 11th Plan to set minimum energy performance standards for new commercial buildings with linked loads of 100 kW and above, as well as to promote energy efficiency in existing structures through retrofitting.

- iii. Star rated equipments :

- 1. During the 11th Plan, a considerable number of appliances were initially covered under the voluntary labelling category, with four appliances/equipment falling under the mandatory labelling programme.

- 2. For example, room air conditioners, refrigerators (direct cool and frost free), and so on, stars are assigned based on their energy usage.

- 3. One factor for the lack of larger-scale DSM programme deployment is limitations in the present regulatory and policy environment.

- 4. Among these flaws is a lack of clarity about distribution utilities’ need to implement DSM measures: There is no clear mandate for State Electricity Regulatory Commissions (SERCs) to establish and implement DSM programmes. There are no regulations or recommendations for designing, developing, or implementing DSM activities.

- 5. In the lack of an overall target/goal, DSM programmes are implemented piecemeal.

- 6. There is also a lack of an institutional system for coordinating EE and DSM efforts across diverse stakeholders such as State Designated Agencies (SDAs), distribution utilities, the Bureau of Energy Efficiency (BEE), and SERCs.

B. International experiences with DSM :

All the DSM measures are being planned and implemented, at least to some extent, in most of the countries in the world.

- i. Load management :

- 1. The United States recognised the necessity of load management quickly after the 1973 oil crisis. More than 1750 load control initiatives have been initiated by more than 500 utilities by 1990.

- 2. There were a total of 13 million loads involved. Water heating systems, space heating systems, and central air conditioning systems were among the loads affected.

- 3. All three forms of controls, direct, local, and distributed, were applied. It has been claimed that load control strategies in the United States have resulted in an average reduction in load ranging from 1 kW/point for winter water heating to 28.7 kW/point for irrigation pumps.

- 4. Utilities in Canada, particularly in Quebec and Ontario, have implemented load management schemes.

- 5. Load management plans have also been implemented in Australia, New Zealand, Italy, France, England, Germany, Switzerland, and a number of other nations.

- 6. It has also been stated that in some nations, load control strategies have resulted in significant Reduced peak energy use.

- ii. End use efficiency :

- 1. Many countries have implemented education initiatives to educate customers about the usage of energy-efficient gadgets.

- 2. Several innovative energy-saving technologies have been created in the United States, Germany, Japan, and other nations.

- 3. It has been stated that, as a result of the adoption of more efficient devices, the average consumption in refrigerators in the United States has decreased from 950 kWh/year to G04 kWh/year, and in deep freezers from T100 kWh/year to 35 kWh/year. These numbers cover the years 1990-1993.

- 4. In Australia, many end-use efficiency schemes, such as cogeneration, marketing and sale of energy-efficient equipment, energy audits, appliance energy labelling, and so on, have been begun and implemented.

- 5. Over the last 15 years, electrical energy consumption in Germany has fallen by around 20% for washing machines, 30% for dish washers, and 45% for freezers.

- 6. In Sweden, improvements in end-of-life efficiency approaches have reduced refrigerator energy use from L4 kWh/litre/year to 0.9 kWh/litre/year.

- 7. Comparable reductions in energy consumption of various appliances have also been recorded from the United Kingdom, France, Japan, and a few other nations.

- iii. Tariffs :

- 1. It is widely acknowledged that providing consumers with incentives and price alternatives is the most effective method to encourage DSM.

- 2. In the United States, bills for water heaters run from $1 to $5 per month, $1.25 to $12 per month for air conditioners, and $1.5 to $29 per horsepower per year for irrigation.

- 3. In addition, several utilities give 7% to 50% rate reductions per kW demand, 8% to 20% rate reductions per kWh, and $ 0.003 to $ 0.061 per kWh savings.

- 4. Several utilities provide annual annoyance fees ranging from $25 to $150.

- 5. In the United Kingdom, a tariff known as ‘Economy 7’ provides electricity at a rate that is less than half that of the daytime rate.

- 6. In Ontario (Canada) DSM programs have resulted in annual savings of $27 to $48 per month.

- 7. Similar incentives and multiple pricing options exist in a large number of countries in Europe and elsewhere.

- iv. Demand response :

- 1. Usage of electrical energy is under the control of consumer.

- 2. This simple fact gave rise to the notion of Demand Response, which is defined as changes in customer power usage in response to tariff changes or incentives to reduce electricity use during peak demand or when the system is in peril.

- 3. It includes all adjustments in electricity usage that are made on purpose in order to consume energy during off-peak hours.

c. Explain in detail objectives of energy audit; give various types of energy audits. Give detailed explanation of each.

Ans. A. Objectives of energy audit :

- 1. To understand the facility’s energetic behaviour.

- 2. To identify the excess of energy consumed.

- 3. To find out the motive of this excess.

- 4. To propose alternate solutions.

- 5. To justify them from technical and economical point of view.

- 6. To determine the ideal energy consumption profiles.

B. Types of energy audits: There are five types of energy audit :

- a. Envelope audit: It surveys the building or factory envelope to determine the energy losses for leakage, construction problems, openings, doors and windows defects, lack of insulation, etc.

- b. Functional audit: It surveys the quantity of energy used for each function such as :

- 1. Heating systems

- 2. Ventilation and air conditioning systems

- 3. Building

- 4. Lighting

- 5. Hot water supply

- 6. Air distribution

- This audit also identifies the energy conservation opportunities in each of these areas.

- c. Process audit: It surveys the quantity of energy required for each process such as :

- 1. Department-wise process plant and machinery

- 2. Heating process

- 3. Ventilation and air conditioning process

- 4. Furnaces

- This audit also identifies the energy conservation opportunities in each process.

- d. Transportation audit: It analyzes the amount of energy required for all sorts of transportation systems in an industry, such as vehicles, cars, trucks, and other material handling equipment. It also identifies opportunities for energy conservation in such transportation networks.

- e. Utility audit: It surveys the quantity of energy required from each utility or support service in an industry.

d. Write in detail different methods of saving energy and increasing the efficiency of Boiler/blowers/compressor/ pumps.

Ans. A. Methods of energy saving pumps :

- 1. Use constant speed AC induction motors to drive the impellers of pumps.

- 2. Do not use oversized motors (higher hp than required).

- 3. Do not operate the pumps if load is not there.

- 4. Clean pumps regularly to avoid frictional losses.

- 5. Ensure sufficient lubrication.

- 6. Use electronic starters.

- 7. Use variable speed motors where the flow and pressure is variable.

- 8. Use pipes, valves and other hardware having minimum frictional loss.

B. Method of increasing the efficiency of pumps: There are many ways to improve the efficiency of pumps:

- 1. Avoid over sizing the pumps.

- 2. Impeller trimming.

- 3. By using variable frequency drives.

- 4. Parallel pumping systems.

- 5. Eliminate unnecessary use.

- 6. Eliminate unnecessary use.

- 7. Limit pipe work pressure loss.

e. Describe the working principle of Automatic Power Factor controller. Its importance. What are the effects of poor power factor on energy efficiency ?

Ans. A. Working of APFC :

- 1. An automatic power factor controller is a device that can automatically modify power factors and adapt the power factor by load variation without requiring manual intervention.

- 2. It is typically installed on reception facilities and power distribution at major users such as apartment buildings and factories to allow full utilization of the electrical infrastructure.

- 3. It detects reactive power requirements automatically and manages the connection of power condensers to achieve the ideal power factor.

- 4. It contains numerous capacitors grouped in several steps, as well as being connected to appropriate switching devices paired with inrush current-limiting devices given for each step.

- 5. Typically, the microprocessor-based automatic power factor controller relay computes the power factor sensed by the current transformer on the line side, as well as the KVAr required to meet the target power factor.

B. Importance :

- 1. Unmanned operation of power factor control.

- 2. Always maintains very good and accurate power factor.

- 3. Results in decreased system current and, hence, reduced voltage drop and power loss automatically.

- 4. Reduces energy bill and avoids penalties both power factor penalty and maximum demand.

C. Effect of poor power factor: The lower power factor means higher current has many disadvantages such as :

- 1. Copper losses are inversely proportional to the square of the power factor, implying that for low power factors, more loss occurs, resulting in poor efficiency.

- 2. A low power factor causes a significant voltage drop in generator transmission lines, transformers, and distributors, leading to poor regulation. As a result, additional equipment is required to make voltage permissible.

- 3. In order to transfer the same amount of power with a low power factor, the transmission cables must carry greater current. As a result, greater conductor material is required for cable to provide the load at low power factor.

- 4. Poor power factor raises the capital cost of transformers, transmission lines, cables, and distributors, among other things.

Section 3 : Energy Conservation act 2001

a. Write short note on-Energy conservation act 2001 and its features.

Ans. A. Energy conservation act 2001 :

- 1. The Indian government enacted the Energy Conservation Act 2001 in response to the potential and benefits of energy conservation.

- 2. This legislation provides a legislative structure and organisation to achieve the energy efficiency push. It successfully bridges the demand-supply gap, saves energy, and decreases environmental emissions.

- 3. The objective of EC act is :

- To promote efficient use of energy and its conservation through certain statutory measures to promote conservation of energy and facilitate its efficient use in various sectors of our country.

B. The salient features of energy conservation act, 2001 are :

Energy conservation act 2001 empowers the union government and in some instances the state government to :

- 1. Inform energy-intensive companies, businesses, and commercial buildings that they are designated customers.

- 2. Establish energy usage guidelines and criteria for certain consumers.

- 3. Instruct the consumer to hire certified energy managers for energy efficiency.

- 4. The government should modify energy-saving building codes to reflect regional and local climatic conditions.

- 5. Require commercial building owners to follow energy conservation construction codes.

- 6. Directly required labelling of alerted equipment and appliances.

- 7. Energy consumption standards for specified equipment and appliances.

- 8. Ban the manufacture, sale, purchase, and import of not-conforming notified equipment and appliances.

- 9. Under the provision of this act the Bureau of Energy Efficiency (BEE) was established with effect from 1.03.2002.

- 10. The mission of the BEE is to institutionalize energy efficiency services, promote energy efficiency delivery mechanism and provide leadership for improvement of energy efficiency in all sectors of the economy.

b. Explain the energy conservation in small scale and large scale industries.

Ans. A. Energy conservation in small scale industries :

- i. Illumination: Industrial lighting needs range from low levels (for general purpose and rough work) to high levels needed for precision work. Substantial savings are possible by use of one or more of the following:

- a. Maximum use of natural light: This usually necessitates the installation of fibre glass skylights in the roof. Electric lighting is separated into circuits that are controlled by photocells. When there is enough natural light, electric bulbs are turned OFF automatically.

- b. Use of high efficiency lamps and luminaires: The efficiency of the bulbs ranges from roughly 10 lumens/watt (for an ordinary incandescent lamp) to about 120 lumens/watt (for low pressure sodium vapour lamp). The fluorescent bulb has a lumen/watt efficiency of 65. Appropriate luminaire selection and arrangement is also critical.

- c. Reduction of illumination to acceptable task levels: It has been discovered that lighting levels are excessive in many places and can be simply adjusted without affecting productivity, efficiency, or worker health.

- d. Improved maintenance and cleaning of lighting equipment and lamps.

- e. Proper lighting control.

- ii. Electric power distribution: The steps which can be taken in this regard are :

- a. Proper design and installation of electric distribution system: The distribution system of the facility should be designed and installed properly.

- b. Improvement of overall power factor of installation: It is well understood that a low power factor results in higher energy losses. Wherever possible, shunt capacitors should be installed to increase power factor.

- c. Reduction of peak loads wherever possible.

- iii. Selection of drives and equipment and their operation at full load: The drives and equipment should be chosen based on life cycle costs rather than startup expenses. This type of selection ensures that the most efficient machines are used. Also, the induction motor is the most widely used AC motor. As a result, induction motors should be run at full load as often as possible.

- iv. Testing facilities: Industries will always require testing facilities to put their products through their paces. The use of energy-efficient testing methodologies, as well as the potential of combining testing of many items, should be encouraged.

B. Energy conservation in large scale industries: The conservation of energy in large scale industry as follows :

- a. Pulp and paper industry: Some energy conservation measures which have been successfully adopted by some pulp and paper industries are :

- Modification of chippers, replacement of batch digesters with continuous digesters, use of medium consistency pumps, use of falling film evaporators (rather than rising film evaporators), waste heat recovery, improvement of power factors of electric motors, and operation of motors at peak efficiency.

- b. Cement industry: The measures which have been successfully implemented in some cement factories for energy conservation are :

- Optimum layout, use of single stage impact type hammer crushers, use of vertical roller mills and high pressure grinding rolls, use of modern pressure grinding rolls, reduction of exit gas temperature, coal beneficiation and pre-blending of coal (so that high ash content coals can be used), improved burners and operation optimisation.

- c. Petroleum refinery: The possible measures for energy conservation in this industry are :

- Adding new heat exchangers to boost the temperature of crude, using air preheaters to exploit the heat of flue gases, using a carbon monoxide boiler to recover the heat content of carbon monoxide, steam re-routing, process adjustments, optimising cooling tower operation, and so on.

- d. Iron and steel industry: The possible measures for energy conservation include :

- Improved sintering plant ignition system, sintering plant heat recovery system, optimum combustion control in coke ovens, flue gas heat control, use of ceramic heat exchangers for oxygen gas, slag heat recovery, direct hot charge rolling, use of gas recuperators in reheating furnaces, scrap preheating system in electric furnaces and so on.

Section 4 : DSM Strategy

a. Explain DSM strategy, its implementation and application.

Ans. A. DSM strategy :

- 1. Peak clipping, also known as peak load reduction, is a traditional technique of load management.

- 2. In this application, several consumer appliances are turned off for a short period of time using direct load control.

- 3. Obviously, these are the appliances that use a lot of electricity and can be disconnected for a while without causing too much trouble.

- 4. It may be more advantageous in the case of huge industrial consumers. Different industries will have varying relative peak clipping potential.

- 5. The ceiling demand that must be enforced in each situation should be determined in cooperation with the participating industry, and the time period required for this should not be greater than the power availability projected for the cluster during that period.

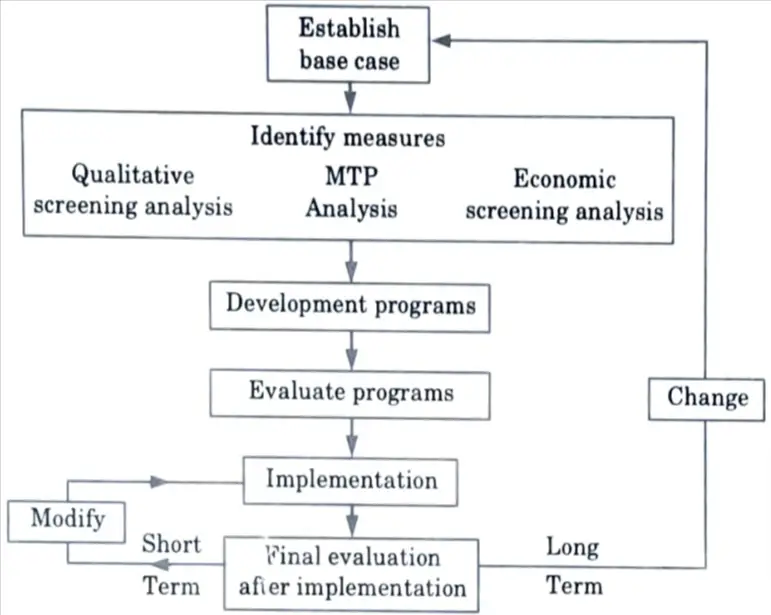

B. DSM implementation and application: DSM planning and implementation can be described in six steps shown in Fig. The steps shown are only representative.

- i. Establish base case: The analyst determines a base case so that the impacts of DSM may be compared against it. The base case is determined for each class of customers. This step includes collection of data about end use efficiencies of various technologies.

- a. Domestic consumer’s base case :

- 1. Domestic end uses of electricity are discovered in this basic instance. These end uses include lighting, water heating, refrigerators, fans, cooking, room cooling and heating, and so on.

- 2. End-use energy consumption is defined and calibrated in order to forecast sales data.

- b. Commercial consumer’s base case: Commercial consumers include school and other educational institutions, offices, hotels and restaurants, hospitals, lodging houses, shops, departmental stores etc.

- c. Industrial consumer’s base case :

- 1. Industrial consumers include small scale, medium scale and large scale industries.

- 2. In addition to size, the type of industry also determines the energy consumption.

- ii. Identify measures: In this step, a comprehensive list of energy conservation and demand management measures for each category of consumers is prepared. The methods of analysis available to determine the best measures to be incorporated by the utility, into DSM program are :

- a. Qualitative screening analysis: In this step the best measures suited to the utility for inclusion in DSM option are identified. Simultaneously the inappropriate measures are eliminated.

- b. MTP (Maximum Technical Potential) analysis :

- 1. The technical potential for measures suitable for that area is estimated in this stage. These measures were already recognised in step 1.

- 2. MTP is restricted to energy-saving methods. This analysis is carried out in two steps.

- 3. The first phase is primarily theoretical because it presupposes that all inefficient equipment can be replaced with the most efficient technology.

- 4. The second analysis is based on the assumption that only consumers who are purchasing new or replacing old equipment (for reasons other than DSM) will adopt and acquire efficient equipment.

- c. Economic screening analysis: This final phase evaluates the cost effectiveness of each measure and performs a cost-benefit analysis. This report gives information on the financial savings associated with each measure. These financial savings serve as the foundation for determining the incentives and rebates that can be offered to clients.

- iii. Development of programs :

- This step includes the following items: programme description, implementation plan (to overcome market barriers), incentives (loans, rebates, etc.) to popularise the programme, participation, load implications, and utility and participant costs (i.e., estimates of likely costs which utility and participating customers will have to bear).

- iv. Initial evaluation of programs :

- a. The suggested DSM programmes’ detailed cost-benefit analysis is performed in this step. In most cases, the cost-benefit analysis is performed more than once.

- b. The repeated computations ensure that only the most effective and cost-efficient programmes are implemented.

- v. Implementation:

- i. The implementation specifics are worked out in this step. The techniques of implementation have been determined. The program’s project manager has been identified.

- ii. The refunds and incentives have been determined. The utility may implement the programme directly or through a contract.

- iii. Several utilities in industrialised nations prefer contract implementation so that the utility does not have to hire additional permanent workers for this purpose.

- vi. Final evaluation of program :

- a. In this step the extent of the success of the program is evaluated.

- b. Process assessment (to see how the implementation is progressing so that bottlenecks may be addressed), impact evaluation (to determine the impact of the programme on demand and energy savings), and cost effective evaluation are all part of the evaluation (to determine the extent of net benefits).

b. What is the difference between DISCOMs, TRANSCO and GENCO ? How UDAY scheme is beneficial discusses ?

Ans. A. Difference :

| S. No. | DISCOMs | TRANSCO | GENCO |

| 1. | These companies receive power from TRANSCO’s and distribute that power to customers i.e., houses, industries, hospitals etc. | These are involved only in transmitting electrical power from generating stations to load centres (DISCOM’s) at high voltage levels (generally above 220 kV level). | They are involved only in business of generating electrical power. |

| 2. | Examples of DISCOM’s are BYPL, BRPL, NDPL. | Examples of TRANSCO are PGCIL (Power Grid Corporation of India Limited), DTL (Delhi Transco limited). | Examples of GENCO are NTPC, NHPC etc. |

B. UDAY scheme :

- 1. In November 2015, the government had started UDAY (Ujwal DISCOM Assurance Yojana) scheme

- 2. This scheme has been approved for the financial turnaround of Power Distribution Companies (DISCOMs).

- 3. The aim of this scheme is to improve the operational and financial efficiency of the state DISCOMs.

Section 5 : Energy Audit Process

a. Explain the methodology for detailed energy audit process.

Ans. A. Phase I-Pre audit phase activities: A organised process for conducting an energy audit is required for efficient operation. An initial site assessment should always be performed, as outlining the procedures required for an audit is critical.

- 1. Initial site visit and preparation required for detailed auditing :

- a. An initial site visit may take one day and allows the energy auditor/engineer to meet with the employees involved, become acquainted with the location, and assess the procedures required to carry out the energy audit.

- b. During the initial site visit the energy auditor/engineer should carry out the following actions :

- i. Discuss with the site’s senior management about aims of the energy audit.

- ii. Discuss economic guidelines associated with the recommendations of the audit.

- iii. Analyse the major energy consumption data with the relevant personnel.

- iv. Obtain site drawings where available – building layout, steam distribution, compressed air distribution, electricity distribution etc.

- v. Tour the site accompanied by engineering/production.

- 2. The main aims of this visit are :

- i. To finalize energy audit team.

- ii. To identify the main energy consuming areas/plant items to be surveyed during the audit.

- iii. To identify any existing instrumentation/additional metering required.

- iv. To decide whether any meters will have to the installed prior to the audit. For example kWh, steam, oil or gas meters.

- v. To identify the instrumentation required for carrying out the audit.

- vi. To plan with time frame.

- vii. To collect macro data on plant energy resources, major energy consuming centres.

- viii. To create awareness through meetings/programme.

B. Phase II-Detailed energy audit activities :

- 1. A comprehensive audit can take several weeks to several months to perform, depending on the scope and complexity of the site.

- 2. Extensive research is conducted to build and investigate energy and material balances for specific plant departments or pieces of process equipment.

- 3. To guarantee that nothing is overlooked, plant operations are checked over extended periods of time, including at night, on weekends, and during normal daily working hours, if practicable.

- 4. The audit report will include a breakdown of energy inputs and outputs by major department or major processing function, as well as an evaluation of the efficiency of each step of the manufacturing process.

- 5. Methods for enhancing these efficiencies will be described, and at least a preliminary cost estimate will be prepared to reflect the estimated payback on any capital investment required.

- 6. The audit report should conclude with specific suggestions for extensive engineering studies and feasibility analyses, which must subsequently be carried out to justify the implementation of conservation measures that necessitate investments.

- 7. The information to be collected during the detailed audit includes :

- i. Energy consumption by type of energy, by department, by major items of process equipment by end-use.

- ii. Material balance data (raw materials, intermediate and final product, recycled materials, use of scrap or waste products, production of by-products for re-use in other industries, etc.)

- iii. Energy cost and tariff data.

- iv. Processes and material flow diagrams.

- v. Generation and distribution of site services (e.g. compressed air, steam).

- vi. Sources of energy supply (e.g. electricity from the grid or self generation).

- vii. Potential for fuel substitution, process modifications, and the use of co-generation systems (combined heat and power generation).

- viii. Energy Management procedures and energy awareness training programs within the establishment.

- 8. Existing baseline data and reports can be used to determine consumption patterns, production costs, and productivity levels based on raw material inputs.

- 9. The audit team should collect the following baseline data :

- i. Technology, processes used and equipment details ii. Capacity utilization

- iii. Amount and type of input materials used

- iv. Water consumption

- v. Fuel Consumption

- vi. Electrical energy consumption

- vii. Steam consumption

- viii, Other inputs such as compressed air, cooling water, etc.

- ix. Quantity and type of wastes generated

- x. Percentage rejection/reprocessing

C. Phase III-Post audit phase.

- 1. Action plan, schedule implementation.

- 2. Follow-up and periodic review.

b. Distinguish between energy conservation and energy audit based on activities.

Ans.

| Basis | Energy Conservation | Energy audit |

| Definition | Energy conservation refers to efforts undertaken to limit energy use. This can be accomplished by either utilising less energy for a steady service or by reducing the amount of service used (for example, by driving less). | Energy auditing entails the verification, monitoring, and analysis of energy usage, as well as the production of a technical report comprising recommendations for improving energy efficiency, cost benefit analysis, and an action plan to reduce energy consumption. |

| Aim | Energy conservation aims to minimise demand, discover and employ alternative energy sources, and clean up the harm caused by previous energy operations. | To comprehend the facility’s energetic behaviour and to discover excess energy consumption. |

| Importance | Energy conservation is vital for preserving nonrenewable energy supplies, as well as for lowering the costs associated with fossil fuels. | An energy audit will find potential for energy savings in systems, wiring, and ventilation. |

| Strategy | Energy conservation strategies can be divided into three types: Strategies for the short term Plans for the medium term Long-term approaches | The energy audit strategy is divided into three steps: Considerations in general preliminary research Extensive research |

Section 6 : Electric Heating Methods

a. Explain in detail how conservation of energy is done in the following process :

i. Space heating Energy audit

ii. air-conditioning

Ans. i. Energy conservation in space heating :

- 1. Limiting heat losses from the building

- 2. Avoid any improper use of heating

- 3. Optimize the output of heat generators

- 4. Use heat pumps

- 5. Use solar heating

- 6. Optimize heating circuits

- 7. Optimize heating control

ii. Energy conservation in air-conditioning :

- 1. Improvements in equipment or system operation.

- 2. Minimizing the load on the system.

- 3. Use a smart thermostat.

b. What are the modes of transfer of heat ? Explain the different types of electric heating methods and method to measure its performance.

Ans. A. Modes of heat transfer :

- 1. Conduction: Conduction is the movement of heat from one part of a substance to another, or from one substance to another in physical contact with it, without considerable displacement of the molecules that make up the substance.

- 2. Convection: Convection is the process through which heat is transferred within a fluid by mixing one section of the fluid with another. Convection is only feasible in a fluid medium and is closely related to the movement of a fluid moving in space, which causes heat exchange.

- 3. Radiation: The transport of heat through space or matter by mechanisms other than conduction or convection is known as radiation. Heat radiation is the same as electromagnetic waves.

B. Methods of electrical heating :

1. Power frequency heating :

a. Resistance heating :

- i. This heating method is based on the I2R effect and has a wide range of applications, including heat treatment of metals (e.g., annealing, normalising, hardening, tempering, etc.), drying and baking of potteries, home cookery, and so on.

- ii. Following are the two methods of resistance heating :

- a. Direct resistance heating

- b. Indirect resistance heating

2. Arc heating :

- i. When a high voltage is applied across an air gap, the air in the gap is ionised by electrostatic forces and becomes a conducting medium.

- ii. Current flows as a continuous spark, known as the arc. When carbon/graphite electrodes are used, the temperature attained ranges from 3000 °C to 3500 °C.

- iii. The high voltage required to strike an arc can be generated by utilising a step-up transformer powered by a variable alternating current supply.

- iv. An arc can also be produced by applying a low voltage across two electrodes that are originally in contact with one another.

- v. The low voltage required for this purpose can be obtained by using a step-down transformer.

- vi. Initially, the low voltage is applied, when the two electrodes are in contact with each other.

- vii. Further, when the two electrodes are gradually separated from each other, an arc is established between the two.

- viii. Following are the two methods of arc heating :

- a. Direct arc heating

- b. Indirect arc heating

3. High frequency heating :

a. Induction heating :

- i. Induction heating employs the currents created by electromagnetic action in the charge to be heated.

- ii. Induction heating, in reality, operates on the transformer concept.

- iii. The main winding, which is powered by an alternating current source, is magnetically connected to the charge, which operates as a single-turn short-circuited secondary.

- iv. When an alternating current voltage is delivered to the primary, it induces voltage in the secondary, resulting in charge.

- v. The secondary current, like any other electric current, heats up the charge as it passes past a resistance.

- vi. If V is the voltage induced in the charge and R is the resistance of the charge, then heat produced = V2T/R.

- vii. In order to generate enough heat to melt the charge, the resistance of the charge must be low, which is only feasible with metals, and the voltage must be higher, which is produced by using a larger flux and frequency.

- viii. Because of their increased permeability, magnetic materials can be treated more easily than nonmagnetic materials.

- ix. Following are the two methods of induction heating :

- Coreless type induction heating

- Direct core-type induction heating.

b. Dielectric heating: Dielectric heating (also sometimes called High frequency capacitive heating) is employed for heating insulators like wood, plastics and ceramics etc., which cannot be heated easily and uniformly by other methods.

Section 7 : Energy Conservation Technique

a. How energy efficiency improvement is achieved in energy efficiency motor for following power loss area :

i. Iron

ii. Stator and Rotor I2R

iii. Friction and windage

Ans. i. Iron :

- 1. Core loss is the amount of energy required to magnetise the core material (hysteresis) and includes losses caused by eddy currents that flow in the core.

- 2. Core losses are reduced by using high-permeability electromagnetic (silicon) steel and prolonging the core to lower magnetic flux densities.

- 3. Eddy current losses are decreased by using thinner steel laminations.

ii. a. Stator :

- 1. They are also called I²R losses which are due to the resistance of stator.

- 2. Stator losses can be reduced by changing the design of the stator slot or by reducing insulation thickness to increase the volume of wire in the stator.

b. Rotor losses I2R :

- 1. It is also called I2R losses which are due to the resistance of rotor.

- 2. Rotor losses can be reduced by increasing the size of the conductive bars and end rings, resulting in a lower resistance, or by decreasing the electrical current.

iii. Friction and windage :

- 1. They are caused by frictional forces at motor shaft bearings. These losses are usually related to the cooling fan.

- 2. The use of a low loss fan design decreases air movement losses.

b. Demonstrate the energy conservation technique adopted in lighting system by using energy efficient luminaries and using light controlled gears.

Ans. To incorporate energy efficiency features in lighting load following system may be used :

- A. Best practices in lighting systems :

- 1. Replace traditional fluorescent lighting with energy-efficient fluorescent lamps (T-5) (T-12).

- 2. Use compact fluorescent lamps (CFLs) instead of incandescent bulbs.

- 3. Use LED panel indication lamps instead of filament bulbs.

- 4. Use of high frequency (HF) electronic ballasts instead of traditional magnetic ballasts.

- 5. Usage of high-efficiency light sources to reduce lighting energy consumption.

- 6. Solar lighting systems are a superior option in rural India because they have no moving components, require no maintenance, and are simple to use.

- B. Energy conservation measures in lighting systems :

- 1. Using LED bulbs as indicator lamps reduces energy usage.

- 2. Using compact fluorescent bulbs instead of incandescent lamps reduces lighting energy consumption by 70%.

- 3. The use of mirror optic fluorescent bulbs significantly boosts the brightness level.

- 4. Using HPSV bulbs instead of MPSV lamps cuts energy consumption by 60%.

- 5. Because illumination level is inversely proportional to square of distance, regulating lamp height will aid in lighting energy saving.

- 6. Electronic ballasts for discharge lamps cut energy consumption by 20%.

- 7. The installation of an intelligent lighting controller will aid in the regulation of lighting energy.

- 8. The use of photosensor switches for street light control aids in the conservation of lighting energy.

2 thoughts on “Energy Conservation and Auditing: Last year Question Paper Questions with Answer”