With the B.Tech AKTU Quantum Book, you can explore the world of Electronic Instrumentation and Measurements. Access critical notes, frequently asked questions, and essential insights for success. Unit-1 Electrical Measurements

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Electronic Instrumentation and Measurements: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 3rd Year * Aktu Solved Question Paper

Q1. What is an instrument ? Classify various types of electrical instruments.

Ans. A. Instrument: It is characterized as a tool for figuring out the amount or value of a quantity or variable.

B. Various types of electrical instruments are:

- a. Absolute instruments:

- 1. These instruments provide the measurement’s magnitude in terms of the instrument’s physical constants.

- 2. Examples are Tangent Galvanometer and Rayleigh’s Current Balance.

- b. Secondary instruments:

- 1. Because of the way these instruments are built, the quantity being measured can only be determined by looking at the output the instrument produces.

- 2. These instruments are calibrated through comparison with an absolute instrument or a different secondary instrument that has already been calibrated against an absolute instrument.

- 3. A voltmeter, glass thermometer, and pressure gauge are a few examples.

- c. Deflection type:

- 1. In instruments of this type, the instrument’s deflection serves as a foundation for figuring out the quantity being measured.

- 2. The quantity being measured causes a physical reaction that causes the instrument’s moving system to deflect or move mechanically.

- 3. To counteract the deflection or mechanical displacement of the moving system, an opposing effect is integrated into the instrument.

- 4. The opposite effect is closely related to the mechanical displacement or deflection that may be seen right away.

- 5. The opposing effect is constructed in such a way that the mechanical or deflection displacement of the moving system, which is the quantity being measured, causes an increase in its magnitude.

- 6. The balance is the mechanical deflection or accomplished movement when the opposing effect equals the cause.

- 7. After that, the displacement at the point of balance can be used to mechanically deduce the value of the measured quantity.

- d. Null type:

- 1. A zero or null indication in a null type of instrument allows one to calculate the magnitude of the amount being measured.

- 2. Several other recognised conditions must also exist for the null condition to exist.

- 3. In contrast to deflection-type instruments, null-type instruments aim to keep the deflection at zero by applying an effect that is in opposition to that produced by the quantity being measured.

- e. Analog type:

- 1. Analog signals are those that vary continuously and can have an endless number of values within a specified range.

- 2. These signals are produced by analogue equipment, as the name suggests.

- f. Digital type:

- 1. Digital signals are those that vary in discrete steps and so only take up a finite number of different values in a given range.

- 2. Digital devices are those that generate these signals.

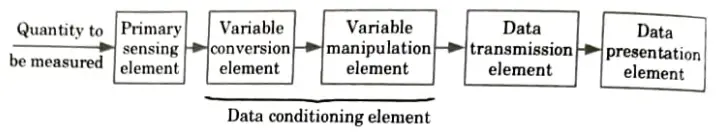

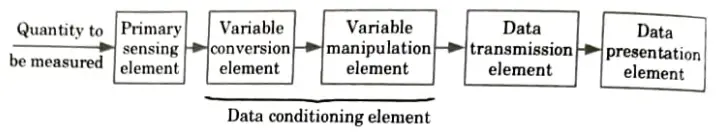

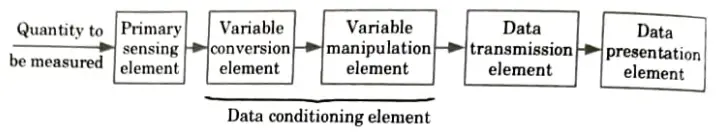

Q2. Discuss with block diagram, generalized instrumentation system.

Ans. Generalized instrumentation system:

A. Primary sensing element:

- 1. The primary sensing component of a measurement system makes initial contact with the quantity being measured.

- 2. The measurement and is then converted into an analogue electrical signal right after this act.

- 3. The transducer is used for this. The detector transducer stage is the initial stage of a measurement system.

B. Variable conversion element:

- 1. The principal sensing element’s output can be any kind of electrical signal. It could be a frequency, voltage, or another electrical property.

- 2. This output may occasionally be inappropriate for the system. It could be essential to convert this output to another suitable form while maintaining the informational content of the original signal in order for the instrument to execute the desired function.

C. Variable manipulation element:

- 1. This element’s purpose is to change the signal that is fed to it while maintaining the signal’s original characteristics.

- 2. In this context, manipulation solely refers to a change in the signal’s numerical value.

- 3. A variable manipulation element is not required to come after the variable conversion element. It frequently comes before the variable conversion element.

D. Data transmission element:

- 1. Data transmission is required when an instrument’s components are truly physically isolated from one another. The component that carries out this action is known as a data transmission component.

E. Data presentation element:

- 1. The persons using the instrument or system must be informed of the quantity being measured in order to perform monitoring, control, or analysis.

- 2. The information must be delivered in a way that the personnel or the intelligent instrumentation system can interpret. The element that presents data serves this purpose.

- 3. Visual display devices are required in the event that data must be monitored. Ammeters, voltmeters, and other analogue or digital indicating instruments may be used in these devices.

- 4. Recorders such as magnetic tapes, high-speed camera and television equipment, storage type CRT, printers, analogue and digital computers, or microprocessors may be employed if the data needs to be stored.

- 5. The terminating stage is the last phase of a measurement system.

Q3. Describe the principle of operation and use of galvanometers.

Ans. A. Construction:

- 1. A galvanometer is essentially a PMMC instrument designed to be sensitive to extremely low current levels.

- 2. The simplest galvanometer is a very sensitive instrument with the type of center-zero-scale as shown in Fig.(a).

- 3. The deflection system is arranged so that the pointer can deflect depending on the direction of current through the moving coil.

B. Working:

- 1. The deflecting torque is inversely proportional to the coil’s size, number of turns, and current flow.

- 2. The taut-ban suspension is used in the most sensitive moving coil galvanometers, and the twist in the suspension ribbon produces the governing torque. Winding the coil on a non-magnetic conducting coil former can produce eddy current damping.

- 4. In some cases, a non-conducting coil former is used, and the moving coil is the only source of the damping currents. In this instance, a damping resistor that limits the amount of eddy currents produced by the coil motions shunts the coil.

- 5. It is common to indicate a critical damping resistance value, which provides just enough damping to allow the pointer to immediately settle down with only a very slight, brief oscillation.

Q4. What do you understand by absolute error and relative error ?

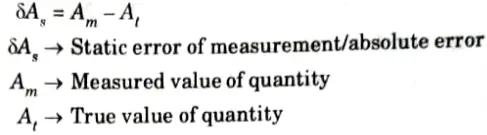

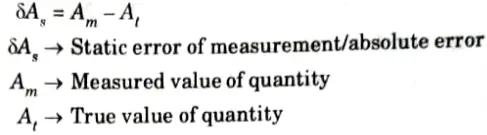

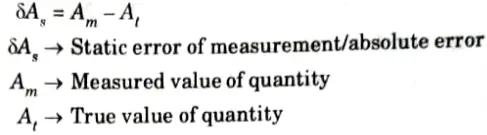

Ans. Absolute errors:

1. The difference between the measured value and the true value a quantity is known as absolute error.

2. Absolute error = Measured value – True value

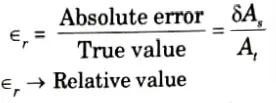

Relative errors:

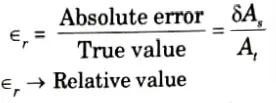

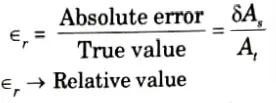

1. It is defined as the ratio of absolute error to the true value of the quantity under measurement is known as relative error.

2.

The relative error can be positive or negative.

Q5. Explain the term “Standards” in measurement system. Also mention the various types of standards used in industry.

Ans. Standards of measurement:

- 1. Measures of electricity A standard is a concrete illustration of the unit being measured.

- 2. The criteria are employed to determine a physical quantity’s value.

- 3. The kilogramme is the basic unit of mass in the international system (SI).

The types of standards are classified by their function and application as:

A. International Standards:

- 1. International accords serve as the foundation for their definition.

- 2. These standards are created to accurately reflect particular units of measurement.

- 3. These standards are routinely compared to absolute measurement in terms of the basic units and examined and appraised.

- 4. The average user cannot access these, which are kept at the International Bureau of Weights and Measures.

B. Primary Standards:

- 1. These absolute standards are so accurate that they can serve as the gold standard for reference.

- 2. National standards laboratories maintain the primary standards.

- 3. The primary standard’s main purpose is to calibrate and verify secondary standards.

Secondary Standards:

- 1. Industrial measurement laboratories employ these as their fundamental reference standards.

- 2. They are tested locally against other reference standards in that region by the industries working on the standards.

- 3. Secondary standards must be maintained and calibrated by a specific industry.

- 4. These standards are periodically delivered to the national standards laboratories for calibration and comparison with the reference standards.

- 5. They are always checked against fundamental principles.

D. Working Standards:

- 1. They are used to calibrate and check the accuracy of common laboratory instruments.

- 2. A precision resistance manufacturer may utilise a standard resistor in his plant’s quality control department to examine the values of the resistors being created.

- 3. In this manner, the maker confirms that his measuring setup operates within the defined ranges of accuracy.

Q6. Explain the concept of swamping resistance. What are the materials generally used for manufacturing these resistances ?

Ans.

- 1. When a moving coil in a PMMC instrument is wound with thin copper wire, variations in temperature can have a considerable impact on the resistance of the coil.

- 2. The heating impact of the coil current can be sufficient to cause a change in resistance. Any such alteration in coil resistance will result in inaccurate ammeter current readings.

- 3. A swamping resistance constructed of manganin or constantan is connected in series with the coil illustrated in Fig. to reduce the impact of coil resistance variation. Resistance temperature coefficients for manganin and constantan are very near to zero.

- 4. The ammeter shunt must also be made of manganin or constantan to avoid shunt resistance variations with temperature.

- 5. In Fig. the swamping resistance must be considered part of the meter resistance Rm when calculating shunt resistance values.

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Electronic Instrumentation and Measurements Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Electronic Instrumentation and Measurements Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One VIew) | Student Result |