Utilization of Electrical Energy and Electric Traction: AKTU Solved Question Paper offers comprehensive tools for test preparation. For the best exam preparation, these answers to the questions help with conceptual comprehension, problem-solving exercise, and topic selection.

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Utilization of Electrical Energy and Electric Traction: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 4th Year

Section A: Short Question Utilization of Electrical Energy and Electric Traction

a. Explain conduction mode of heat transfer.

Ans. Conduction is the movement of heat from one part of a substance to another, or from one substance to another in physical contact with it, without considerable displacement of the molecules that make up the substance.

b. How is control of power affected in electric air arc furnaces ?

Ans. Arc furnace power input can be adjusted by raising or lowering the electrodes or altering the voltage provided to the arc furnace (by changing of tapping on supply transformer).

c. Define the term electric welding.

Ans. Welding is the technique of putting two pieces of metal together so that bonding occurs at their original boundary surfaces.

d. What are the various current collection systems ?

Ans.

- 1. Conductor rail system

- 2. Overhead system.

e. Why is tungsten selected as the filament material ?

Ans. Tungsten is the most often used metal for filament because of its high melting point (3400 °C), high resistivity, low temperature coefficient (0.0051), low vapour pressure, and ability to bear vibration during operation.

f. State and explain refrigeration process.

Ans. It is the controlled reduction of an object’s temperature from its typical surrounding temperature in order to cool it.

g. Give examples of various traction systems in daily life.

Ans.

- i. Electric trains

- ii. Trolley buses

- iii. Diesel-electric vehicles.

h. What is meant by schedule speed of a train ?

Ans. It is the ratio of the total distance between two stop and the total time of run between them.

i. Why the magnetic circuit of a traction motor is not made of cast iron ?

Ans. Because it has less mechanical strength and cannot withstand continuous vibrations.

j. State the significant features of traction drives.

Ans.

- 1. To accelerate the heavy mass, a large torque is necessary during start and acceleration.

- 2. The motor is subjected to torque overloads during acceleration and uphill travel.

- 3. For economic reasons, single phase power is employed in AC traction. Indian Railways use a single-phase 25 kV, 50 Hz supply.

- 4. The locomotive ratings might be as high as 6000 HP. Again, the substation ratings are low due to economic considerations. As a result, the traction supply is weak, and the locomotive supply voltage varies widely.

Section B: Long Questions Utilization of Electrical Energy and Electric Traction

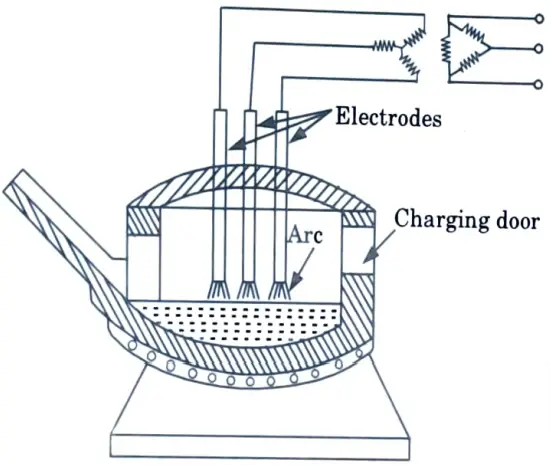

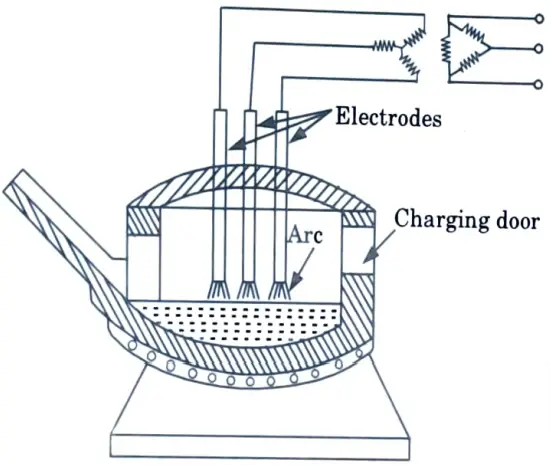

a. Explain the working of arc furnaces and describe with the help of a sketch the construction and working of any one type of arc furnace.

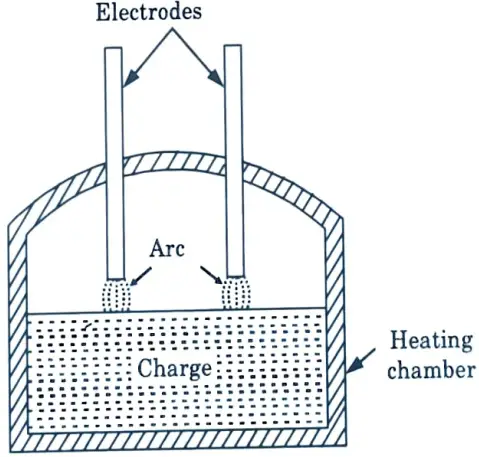

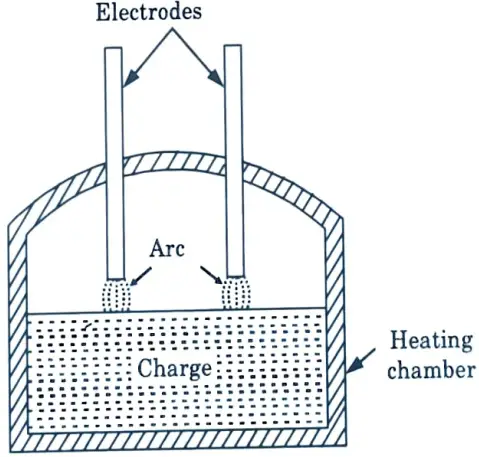

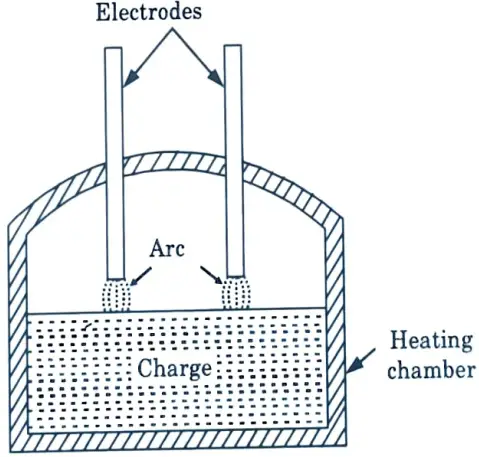

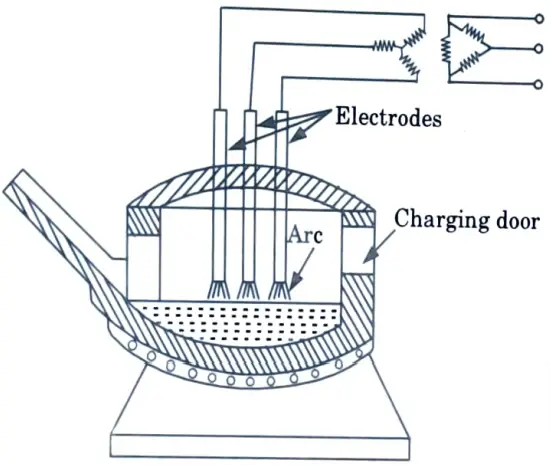

Ans. Direct arc furnace :

- 1. In this type of furnace arc is formed between the two electrodes and the charge in such a way that electric current passes through the body of the charge. Such furnaces produce very high temperatures.

- 2. Fig. shows 1-phase direct arc furnace. Fig. shows a 3-phase direct arc type furnace.

- 3. Both of them consist of a circular steel casting lined inside with refractory material. The roof is removable and a spare is usually kept for rapid replacement.

- 4. The roof in 3ɸ direct arc furnace is provided with three holes through which electrodes are passed. The electrodes may be of graphite or amorphous carbon.

- 5. The graphite has double the conductivity and will carry 2.5 times the current.

- 6. Hence, the graphite electrodes are usually about two third the diameter of amorphous carbon electrodes.

- 7. To maintain the required duration of the arc, electric motors controlled by automatic regulators elevate and lower the electrodes independently.

- 8. The voltage between the steel and the electrodes can range between 40 and 145 volts; the longer the arc, the higher the voltage required a.i the less heat input to the furnace.

- 9. Electric power is delivered in bulk as three-phase alternating current at 6.6 or 10 kV.

- 10. A transformer installed near the boiler reduces the voltage to that required for the arcs, and its primary windings have tappings to enable for arc voltage modifications.

- 11. Due to the fact that the power supply is a three-phase circuit, three electrodes are positioned in an equilateral triangle above the metal.

- 12. Owing to low voltage required by the arc, the current must be very high to obtain the desired output. It operates at a power about 0.8 lagging.

b. Explain arc blow effect at the edges and due to ground currents. What are the advantages of using coated welding electrodes ?

Ans. A. Arc blow effect :

- 1. Arc blow refers to the deflection of the arc from the weld site.

- 2. This problem only occurs with DC welding equipment and is most visible while welding with bare electrodes. It is most noticeable when utilising currents more than 200 A or less than 40 A.

- 3. Arc blow reduces heat penetration in the required area, resulting in partial fusion and bead porosity, as well as excessive weld spatter.

- 4. Arc blow can be prevented by utilising AC welding machines rather than DC welding machines because reversing currents in the welding leads produce magnetic fields that cancel each other out, so eliminating arc blow.

B. Advantage of coated electrodes :

- 1. Arc has been stabilised (since the coating contains compounds of sodium and potassium).

- 2. The contaminants on the welding surface are removed by fluxing.

- 3. Slag is created above the weld, protecting it from ambient contamination, uniformly cooling it, limiting brittleness changes, and providing a smoother surface by reducing ‘ripples’ caused by the welding operation.

- 4. Metal sputtering is avoided while welding.

- 5. Because of the enhanced melting rate, the welding operation becomes faster.

c. Define air conditioning. On what factor does the air conditioning depends ? Explain in detail.

Ans. A. Air conditioning: An air-conditioning system is an assembly of several pieces of the system used to provide a particular condition of air within a needed building space.

B. Air conditioning depends on the following factors :

- 1. Temperature: Effective temperature regulation of the air medium surrounding the body eliminates a physiological stress of accommodation, resulting in increased comfort and improved physical well-being and health.

- 2. Humidity: A considerable part of body heat is lost through evaporation from the skin. Because evaporation is facilitated by low relative humidity of the air and is related to high humidity, humidity control has a significant impact on comfort. Excessive humidity not only causes adverse physiological relationships, but it also affects the qualities of numerous substances in the treated environment, particularly clothing and furnishings.

- 3. Air motion: Air movement over the body raises the rate of heat and moisture dissipation above the rate of still air, altering the sensation of warmth or coolness. There are gratifying and unpleasant consequences depending on the quantity of motion.

- 4. Air purity: Even if the temperature and humidity levels are within normal limits, breathing contaminated air causes discomfort. As a result, effective air filtration, cleaning, and purification are required to maintain it free of dust, debris, and other contaminants.

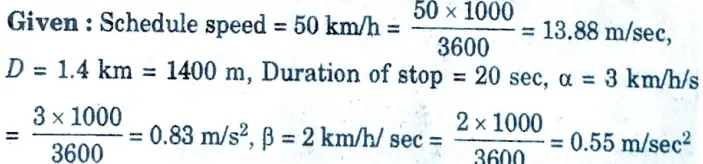

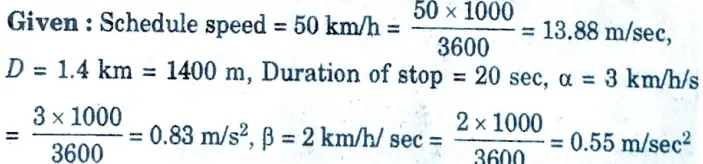

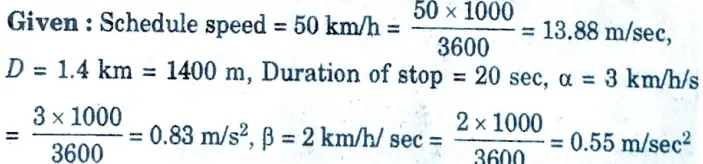

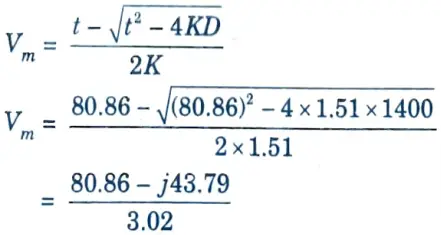

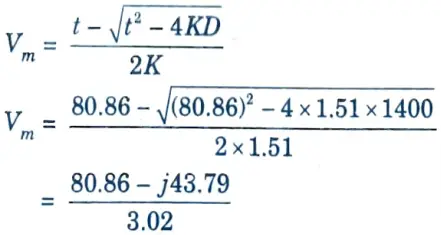

d. The distance between two stops is 1.4 km. A schedule speed of 50 kmph is required to cover that distance. The stop is of 20 seconds duration. The values of the acceleration and retardation are 2 kmph and 3 kmph, respectively. Then, determine maximum speed over the run. Assume a simplified trapezoidal speed-time curve.

Ans.

To Find: Maximum speed, Vm.

1. Schedule time of run,

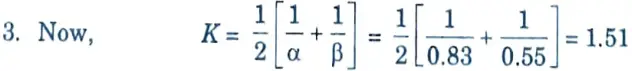

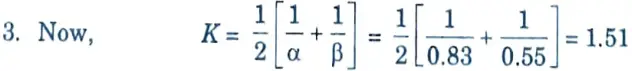

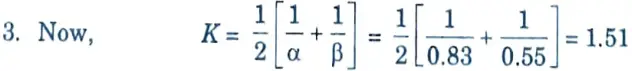

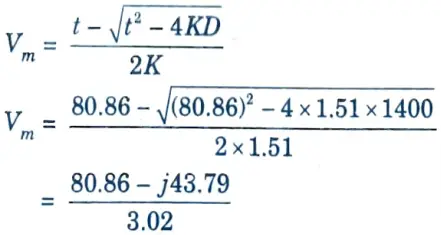

2. Actual time of run, t = 100.86 20 = 80.86 sec

4. Maximum speed,

Further this question cannot be solved because the determined value of maximum speed is in the terms of imaginary.

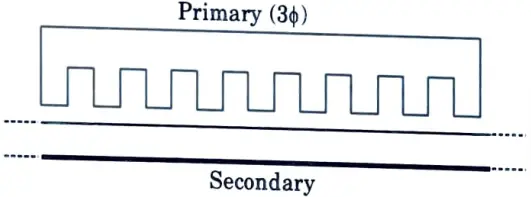

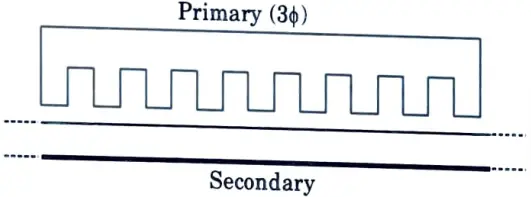

e. Explain the theory, working and characteristics of linear induction motor for traction purposes.

Ans. Linear induction motor :

Construction :

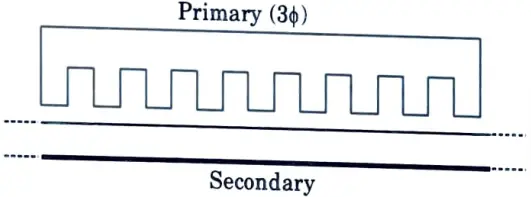

1. A linear induction motor, in its simplest form, consists of field system having a 3ɸ distributed winding placed in slots as shown in Fig.

2. The field system might be single or dual primary. The secondary of this sort of induction motor is often a conducting plate made of copper or aluminium that induces interaction currents.

Working :

1. When the 3ɸ primary winding of the motor is energized from a balanced three phase source, a magnetic field moving in a straight line from one end to other at a linear synchronous speed Vs is produced.

2. The linear synchronous speed Vs is given as:

Vs = 2 𝞃 f m/s

where, 𝞃 = Pole pitch in metres, and

f = Supply frequency in Hz.

3. As the flux moves linearly, it drags the rotor plate along with it in the same direction with speed V. Consequently the relative speed of travel of the flux w.r.t. rotor plate decreases.

4. Slip of the motor(s) is given as

where, Vs = Linear synchronous speed, and

V = Actual speed of the rotor plate.

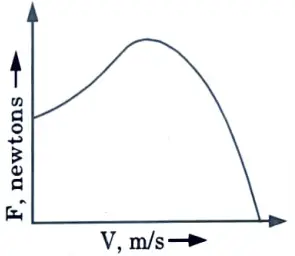

5. Thrust or force or tractive effort (F) is given as:

where, P2 = Actual power supplied to the rotor.

6. Also, copper losses in rotor = sP2,

and mechanical power developed, Pmech = (1 – s)P2

7. Fig. shows the thrust or tractive effort-speed characteristics. In a linear induction motor the following peculiar effects are encountered :

i. End effect.

ii. Transverse edge effect :

a. Because the secondary of this motor is a solid conducting state, the pathways of the induced currents in the secondary are not clearly defined.

b. The section of the current routes parallel to the secondary’s direction of motion contributes nothing to the production of usable thrust but simply contributes to losses.

c. The transverse edge effect reduces thrust and increases losses.

Section 3: Questions Solved Utilization of Electrical Energy and Electric Traction

a. Explain the method of induction heating and describe coreless type of induction furnace.

Ans. A. Method of induction heating :

- 1. Induction heating employs the currents created by electromagnetic action in the charge to be heated.

- 2. Induction heating, in fact, operates on the transformer concept.

- 3. The main winding, which is powered by an alternating current source, is magnetically connected to the charge, which acts as a single-turn short-circuited secondary.

- 4. When an alternating current voltage is given to the primary, it induces voltage in the secondary, resulting in charge.

- 5. The secondary current, like any other electric current, warms up the charge as it passes past a resistance.

- 6. If V is the voltage induced in the charge and R is the resistance of the charge, then heat produced = V2T/R.

- 7. So to develop heat sufficient to melt the charge, the resistance of the charge must be low, which is possible only with metals, and voltage must be higher, which is obtained by employing higher flux and higher frequency.

- 8. Magnetic materials, therefore, can be easily treated than non-magnetic materials because of their higher permeability.

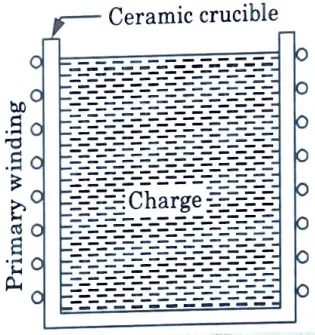

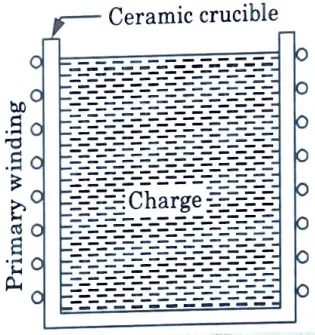

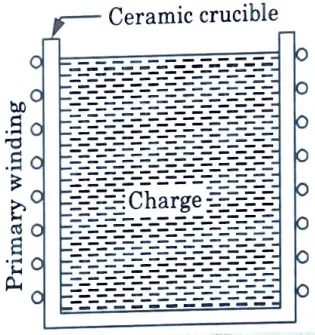

B. Coreless type of induction furnace :

Construction :

- 1. Fig. shows a simplified schematic diagram of a coreless type induction furnace. It essentially consists of three main parts :

- i. Primary coil,

- ii. Ceramic crucible containing charge which forms the secondary

- iii. Frame which includes supports and tilting mechanism.

- 2. The distinctive feature of this furnace is that it contains no heavy iron core with the result there is no continuous path for the magnetic flux.

- 3. The crucible and the coil are relatively light in construction and can be conveniently tilted for pouring.

Working :

- 1. The charge is placed in the crucible, and the primary winding coil is connected to a high frequency alternating current supply.

- 2. The flux induced by the primary winding causes eddy currents in the charge to flow concentrically with those in the inductor.

- 3. These eddy currents heat the charge to its melting point while also creating electromagnetic forces that produce stirring action, which is required for uniform metal quality.

- 4. Since flux density is low (due to the absence of the magnetic core) high frequency supply has to be used because eddy current loss, Pe ∝B2 f2.

- 5. However, because of the skin effect, the resistance of the primary winding increases, increasing primary copper losses.

- 6. As a result, the primary winding is not formed of copper wire but of hollow copper tubes that are cooled by water flowing through them.

- 7. The furnace power factor is between 0.1 and 0.3 because the magnetic coupling cap between the primary and secondary windings is low.

- 8. In order to improve the power factor, static capacitors are generally used in parallel with such a furnace.

- 9. Because the power factor in this sort of furnace does not remain constant, the capacitance in the circuit during the heat cycle is changed to maintain an approximate unity power factor.

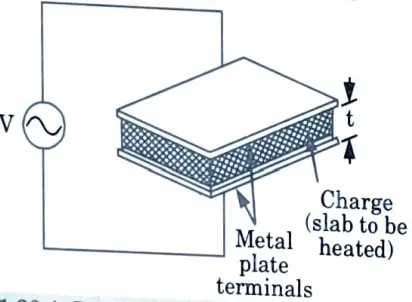

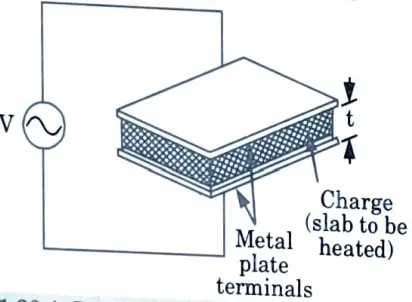

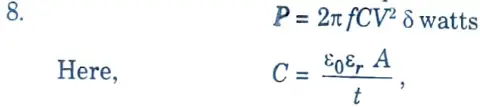

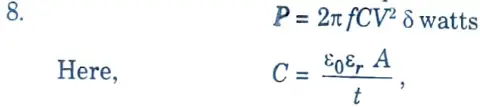

b. What is dielectric heating ? Explain the factors on which the dielectric loss in a dielectric material depends.

Ans. A. Dielectric heating: Dielectric heating (also known as high frequency capacitive heating) is used to heat insulators such as wood, polymers, and ceramics that cannot be heated quickly and uniformly using other methods.

Principle of dielectric heating :

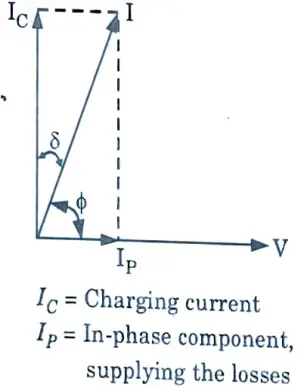

- 1. When a capacitor is subjected to a sinusoidal voltage, the current drawn by it is never exactly 90° ahead of the voltage.

- 2. Because the angle between current and voltage is slightly smaller, there is a minor in-phase component of the current that causes power loss in the capacitor’s dielectric.

- 3. At ordinary frequency of 50 Hz such loss may be small enough to be negligible but at high frequencies the loss becomes large enough to heat the dielectric. It is the loss that is utilized in heating the dielectric.

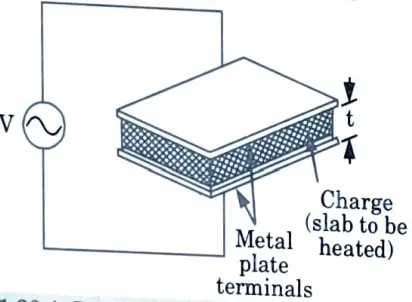

- 4. The insulating material to be heated is placed between two conducting plates in order to form a parallel-plate capacitor as shown in Fig.

- 5. The vector diagram of the capacitor is shown in Fig.

- 6. Power drawn from supply = VI cos ɸ

where δ is very small and is expressed in radians

where t and A are the thickness and area of the dielectric slab respectively; єr is the relative permittivity of dielectric and є0 is the absolute permittivity of vacuum (=8.854 x 10-12 F/m).

- 9. This power is converted into heat. Since for a given insulation material C and δ are constant, the dielectric loss a V2f That is why high-frequency voltage is used in dielectric heating.

B. Factors: The dielectric loss depends on the frequency of the dielectric material and the supply voltage.

Section 4: Question with Solution Utilization of Electrical Energy and Electric Traction

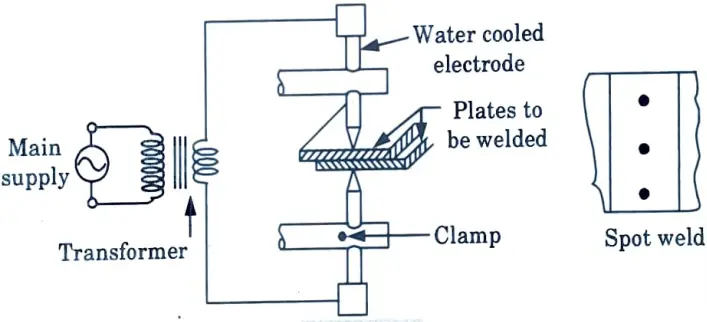

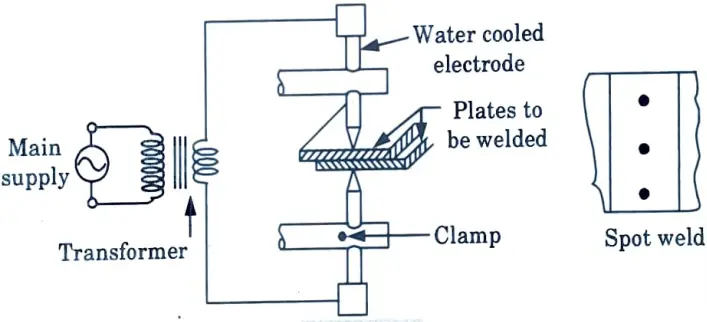

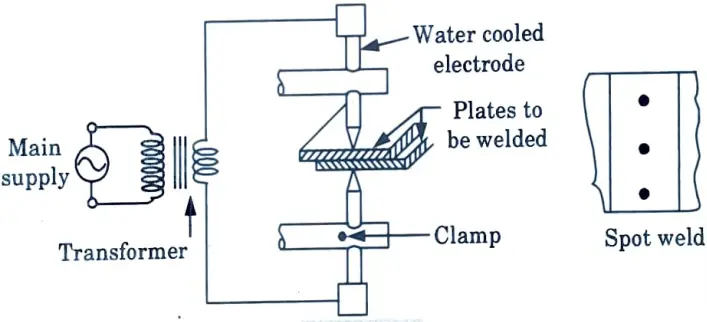

a. Draw a neat sketch of a spot welding machine and describe its construction and working in detail.

Ans.

- 1. Steel, brass, copper, and light alloys can be bonded using this approach, which is a low-cost and satisfactory alternative to riveting.

- 2. In fact, the area of fusion at each spot weld is approximately equivalent to the cross-sectional area of the rivet used for a corresponding gauge of material.

- 3. Spot welding is performed by overlapping the edges of two sheets of metal and fusing them together between copper electrode points at appropriately spaced intervals using a high electrical current.

- 4. The resistance to current provided by the metal as it travels through it raises the temperature of the metal between the electrodes to welding heat.

- 5. The current is turned off, and the electrodes apply mechanical pressure to forge the weld. The electrodes finally open.

- 6. When joining sheets of different thicknesses, the current and pressure settings for the thinner sheets are employed.

- 7. Galvanized, tinned, and lead-coated sheets, as well as mild steel sheet work, are subjected to spot welding.

- 8. This technique is also applied to non-ferrous metals such as brass, aluminium, nickel and bronze etc.

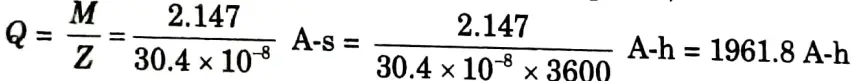

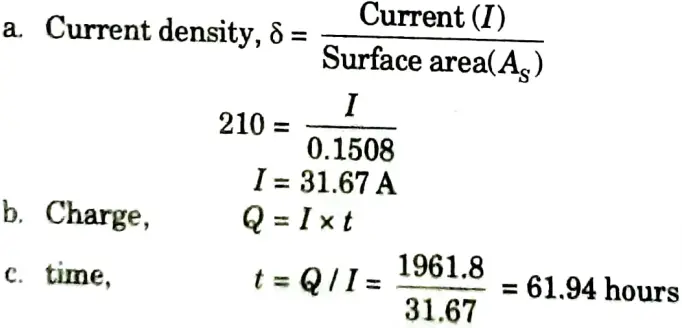

b. It is required to repair a worn out circular shaft 15 cm in diameter and 32 cm long by coating it with a layer of 1.6 mm of nickel. Determine the theoretical value of quantity of electricity required and time taken if the current density used is 210 A/m². Electro-chemical equivalent of nickel is 30.4 x 10-8 Kg/C of electricity and density of nickel is 8.9 x 103 Kg/m3.

Ans. Given: d = 15 cm = 0.15 m, l = 32 cm = 0.32 m,

Thickness of coating = 1.6 mm = 0.0016 m, Current density,

δ = 210 Am², Z = 30.4 x 10-8 kg/c, ρ = 8.9 x 103 kg/m3.

To Find: Quantity of electricity required (Q), time taken, (t).

1. Quantity of electricity required, Q :

a. Surface area of the shaft to be repaired;

As = 𝜋d x l = 𝜋 x 0.15 x 0.32 = 0.1508 m²

b. Mass of nickel to be deposited,

m = Surface area x thickness of coating x density of nickel

= 0.1508 x 0.0016 x 8.9 x 103 = 2.146 kg

c. Theoretical value of quantity of electricity required,

2. Time taken, t :

Section 5: Very Long Questions of Utilization of Electrical Energy and Electric Traction

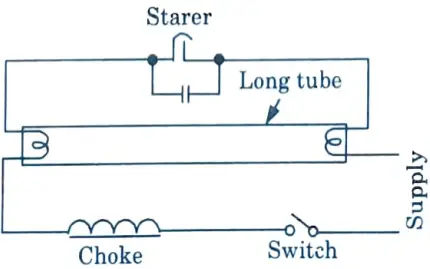

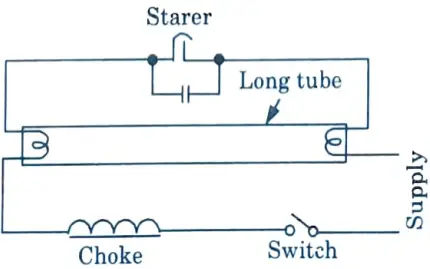

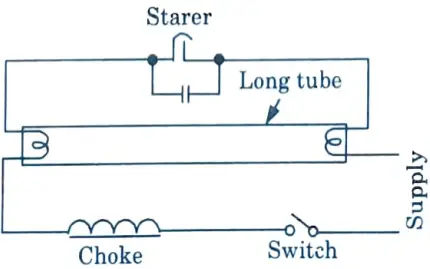

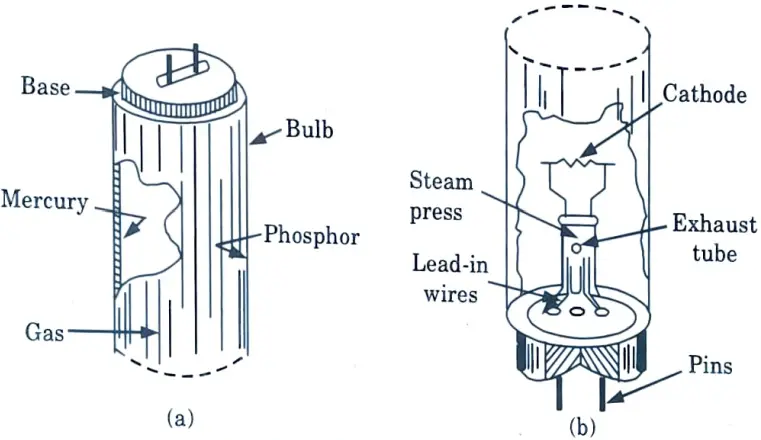

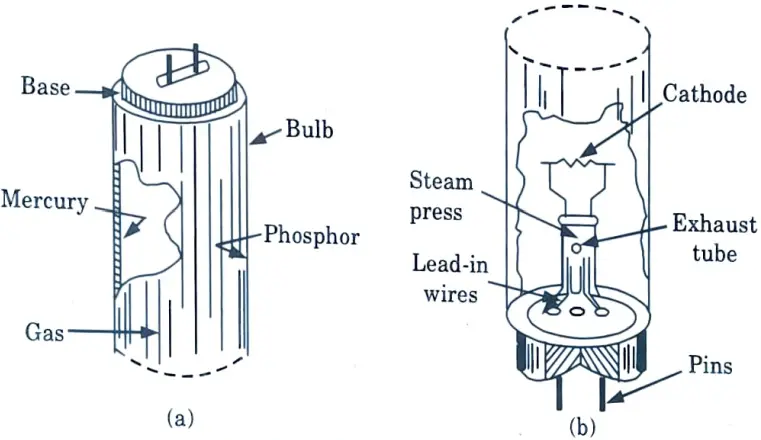

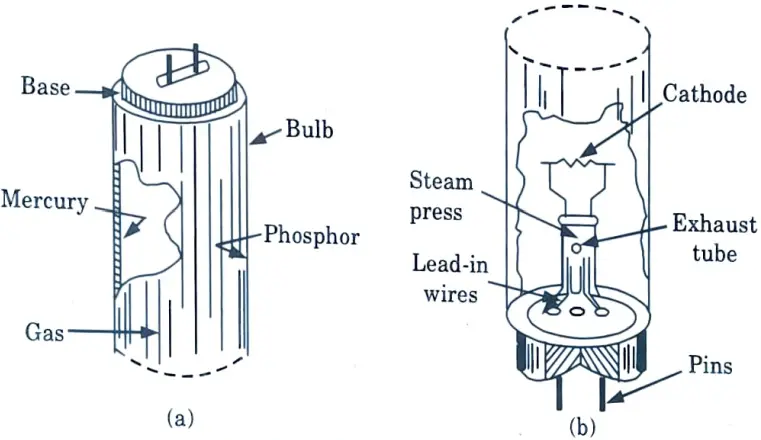

a. Explain the working of a fluorescent tube with the help of the circuit diagram giving the function of various parts.

Ans. Fluorescent tube :

- 1. These tubes are available in a number of lengths and with a choice of colour lighting.

- 2. It is feasible to produce relatively high illumination intensities without significant temperature rises, and the danger of glare is avoided due to the nature of light sources.

- 3. Fluorescent lamps have an efficiency of roughly 40 lumens/watt, which is three times that of an identical tungsten filament lamp.

Construction :

- 1. It is a mercury vapour lamp with a low pressure. Because of the low pressure, the lamp takes the shape of a long tube with a phosphor coating on the interior.

- 2. With a pressure of 2.5 mm of mercury, the tube contains a little amount of mercury and a minor amount of argon gas.

- 3. At each end of the tube, spiral tungsten electrodes are coated with an electron emitting substance.

- 4. The tube filament is linked in series with a choke. It delivers a voltage impulse to start the lamp and then works as a ballast when the bulb is turned on.

- 5. The filament is linked to a starter switch, which is a miniature cathode glow lamp with a bimetal strip between the electrodes.

Working :

- 1. The electrodes are open when the starter is cold. When power is turned on, the starter receives full voltage.

- 2. In the starter, a glow discharge is generated up, which warms the electrodes and causes the bimetal strip to bend and touch the electrodes. The circuit is transformed into a full series.

- 3. Current flows, causing free electrons to be emitted from filaments.

- 4. At the same moment, the starter’s voltage drops to zero and the bimetal strip cools.

- 5. The starter switch’s electrodes then open, interrupting the current in the circuit.

- 6. Its goal is to generate a large voltage spike of approximately 1000 volts in the choke.

- 7. This voltage produces the flow of electrons between the lamp electrodes and the lamp lights up immediately. Then starting contacts are left open.

- 8. In order to improve the power factor, usually a condenser of 4 uF capacity is connected across the supply.

b. A room with an area of 6 x 9 m is illustrated by ten 80-W lamps. The luminous efficiency of the lamp is 80 lumens/W and the coefficient of utilization is 0.65. Find the average illumination.

Ans. 1. Room area = 6 x 9 = 54 m²

2. Total wattage = 80 x 10 = 800 w

3. Total flux emitted by 10 lamps

= 80 x 800 = 64000 lumens

4. Flux reaching the working plane

= 64000 x 0.65 = 41600 lumens

Section 6: Explained Question Utilization of Electrical Energy and Electric Traction

a. What is tractive effort of a train and what are its functions ? Derive an expression for the tractive effort developed by a train unit.

Ans. Tractive effort :

a. Effective force necessary to propel the train at the wheels of locomotive is known as tractive effort.

b. Functions of tractive efforts :

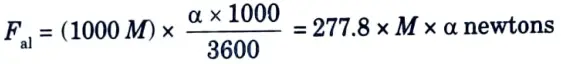

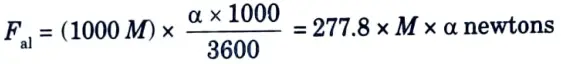

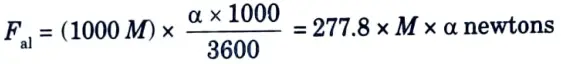

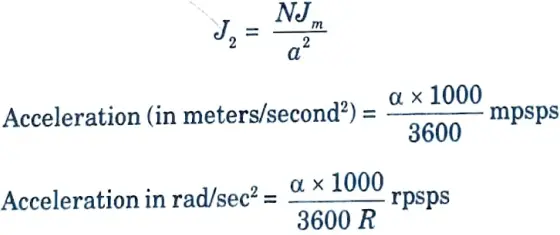

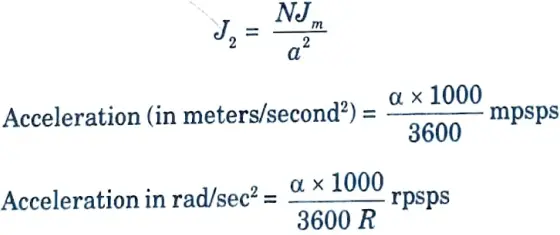

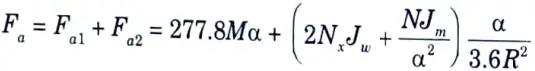

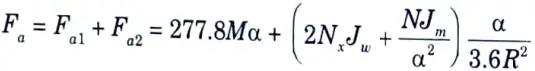

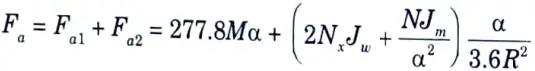

i. Tractive effort required to accelerate the train mass : This has horizontal tractive effort (in newtons) at an acceleration of α kmphs

where M is the mass in tonnes.

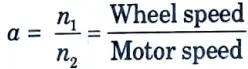

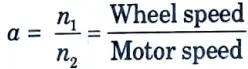

ii. Tractive effort required to accelerate the rotating parts :

1. Moment of inertia of wheels

J1 = 2NxJw

where Jw is the moment of inertia of one wheel in kg-m2 and Nx the number of axles on the train.

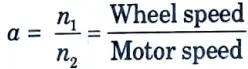

2. Let, N = Number of driving motors

n1 = Teeth on motor gear wheel

n2 = Teeth on axle gear wheel

R = Radius of the wheel, m

Jm = Moment of inertia of one motor, kg-m²

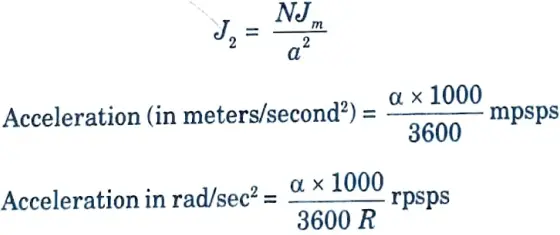

3. Then moment of inertia of motors referred to wheels

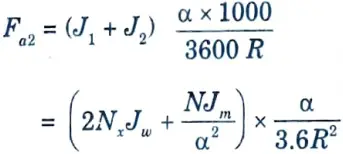

4. Tractive effort for driving rotating parts

5. Total tractive effort required for accelerating the train on a level track (in newtons)

= 277.8 Me α newtons where Me is defined as the effective mass of the train.

b. What are the advantages of single-phase low frequency system of track electrification ? What are the factors due to which its wide spread application remains limited ?

Ans. A. Advantages of low frequency AC supply :

- 1. Apart from increasing the commutation qualities of AC motors, low frequency AC supply boosts their efficiency and power factor.

- 2. Since line reactance is lower at low frequencies, line impedance and hence line voltage loss are lowered. Because of the lower line drop, the substations can be spaced 50 to 80 kilometres apart.

- 3. The low frequency operation of overhead line reduces the communication interferences.

B. Factors limiting wide spread application :

- 1. Current unbalance.

- 2. Voltage unbalance.

- 3. Production of harmonics.

Section 7: Well Defined Questions of Utilization of Electrical Energy and Electric Traction

a. Discuss the problem associated with diesel-electric traction and indicate how these are overcome in practice.

Ans. A. Problem associated with diesel-electric traction (Disadvantages) :

- 1. High initial cost.

- 2. High weight.

- 3. Low life.

- 4. Regenerative braking not possible.

- 5. They do not have high starting torque.

B. Problem overcome :

In diesel electric locomotives, regenerative braking is not possible but, if required, the rheostatic braking can be employed.

b. How direction of rotation of a traction motor is reversed ? Explain the working principle of metadyne control of traction motor. Also discuss its merits and demerits.

Ans. The traction motor’s rotational direction is reversed by reversing the connections to the motor field windings using a reverser.

B. Metadyne control :

- 1. There is a significant loss of energy in the starting resistances during series-parallel control of DC traction motors.

- 2. The metadyne control system assesses energy loss and achieves extremely smooth control during the accelerating period.

- 3. Metadynes are machines that have more than two brush sets per pair of poles.

- 4. It is a device that converts constant voltage and variable current power into constant current and variable voltage power.

Merit :

- 1. The loss is significantly lower than in the case of the resistance starting approach.

- 2. A uniform tractive effort is developed, avoiding the train’s choppy surroundings.

- 3. It is possible to achieve regenerative braking down to zero speed.

- 4. Energy savings during acceleration and braking can readily offset the higher expense of the more complex equipment necessary for metadyne control.

Demerit: It is most suitable for DC traction motor only.

2 thoughts on “Utilization of Electrical Energy and Electric Traction: AKTU Solved Question Paper”