The Quantum Notes from Aktu will help you learn more about Concrete Technology. For the best results in your B.Tech courses, learn important ideas and frequently asked questions. One-step success! Unit-3 Mix Design and Rhealogy of Concrete

Dudes 🤔.. You want more useful details regarding this subject. Please keep in mind this as well. Important Questions For Concrete Technology: *Quantum *B.tech-Syllabus *Circulars *B.tech AKTU RESULT * Btech 3rd Year * Aktu Solved Question Paper

Q1. What do you mean by ‘mix design’ in concrete? Explain its types and objectives.

Ans. Concrete Mix Design: In order to get the desired qualities of concrete in the most cost-effective manner, mix design is the science of calculating the relative quantities of the elements.

Types of Mixes: Following are the types of mixes:

- 1. Nominal Mixes: The proportions of cement, fine aggregates, and coarse aggregates are specified in the standards for concrete. Nominal mixes are those with a predetermined cement to aggregate ratio that guarantee acceptable strength.

- 2. Standard Mixes: IS 456-2000 has designated the concrete mixes into a number of grades as M10, M15, M20, M25, M30, M35 and M40. In this designation the letter M refers to the mix and the number to the specified 28 day cube strength of mix in N/mm2.

- 3. Design Mixes: With the exception of the minimum cement content, which can be set, the concrete producer determines the mix proportions while the designer specifies the performance of the concrete in these mixtures.

Objective of Mix Design: Following are the objective of mix design:

- 1. To achieve the designed/desired workability in the plastic stage.

- 2. To achieve the desired minimum strength in the hardened stage.

- 3. To achieve the desired durability in the given environment conditions.

- 4. To produce concrete as economically as possible.

Q2. Discuss the Abram’s water/ cement ratio law and its validity. How strength of concrete is estimated by Abram’s law.

Ans. Abram’s Water/ Cement Ratio Law :

- 1. In accordance with Abram’s law, the water-cement ratio has an inverse relationship with the strength of thoroughly compacted concrete.

- 2. The weight ratio of the water and cement in this combination is known as the water-to-cement ratio. The water-to-cement ratio should be between 0.4 and 0.5 for the majority of applications, lower for lesser permeability and higher for strength.

Validity: Large valids will be present in the concrete mix if it is not thoroughly compacted, which increases porosity. Abram’s law is therefore invalid at low water/cement ratios when complete compaction is challenging to achieve.

Expression:

1. According to Abram’s law, compressive strength can be expressed as:

Q3. Step by step explain the American Concrete Institute method of mix design.

Ans. Following are the steps in American Concrete Institute method:

- 1. Data to be Collected:

- i. Fineness modulus of selected fine aggregate.

- ii. Unit weight of dry rodded coarse aggregate.

- iii. Specific gravity of coarse and fine aggregates in SSD condition

- iv. Absorption characteristics of both coarse and fine aggregates.

- v. Specific gravity of cement.

- 2. Calculate the average design strength using standard deviation from the minimum strength supplied.

- 3. Calculate the water-to-cement ratio using the strength and durability as your starting points. Use the lesser value.

- 4. Choose the largest aggregate that will be used. Pre-stressed concrete in the size of 10 mm and RCC in the size of 20 mm are typically employed.

- 5. Determine the job’s workability in terms of slump.

- 6 The total water in kg/m3 of concrete is determined, corresponding to the selected slump and selected maximum size ot aggregate.

- 7. The cement content is calculated by multiplying the water/cement ratio by the total water content.

- 8. For the specific maximum size of coarse aggregate and fineness modulus of fine aggregate, choose the bulk volume of dry rodded coarse aggregate per unit volume of concrete.

- 9. In order to determine the weight of CA per cubic metre of concrete, the bulk volume and bulk density must be multiplied.

- 10. By knowing the specific gravity of CA, it is possible to compute the solid volume of coarse aggregate in a cubic metre of concrete.

- 11. One cubic metre of concrete’s solid cement, water, and air contents are also computed.

- 12. The solid volumes of cement, CA, water, and trapped air are subtracted from the total volume of concrete to calculate the solid volume of FA.

- 13. The solid volume of fine aggregate is multiplied by the specific gravity of FA to determine the weight of the material.

Q4. What do you mean by Rheology of fresh concrete ? Explain the parameters of Rheology.

Ans. 1. Rheology: It can be characterized as the study of the flow and deformation of materials and the interactions between time, stress, strain, and strain rate.

2 Rheology is the study of materials whose flow characteristics differ from those of simple fluids (liquids or gases).

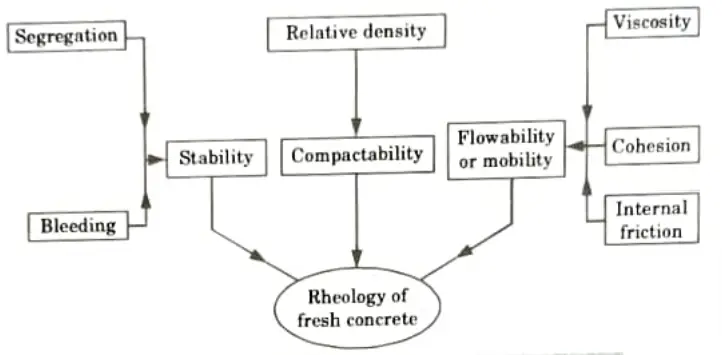

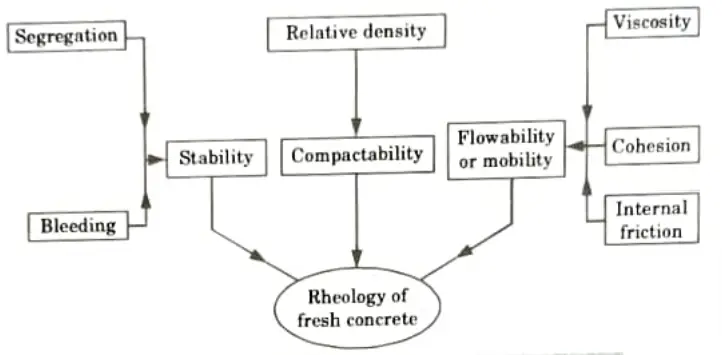

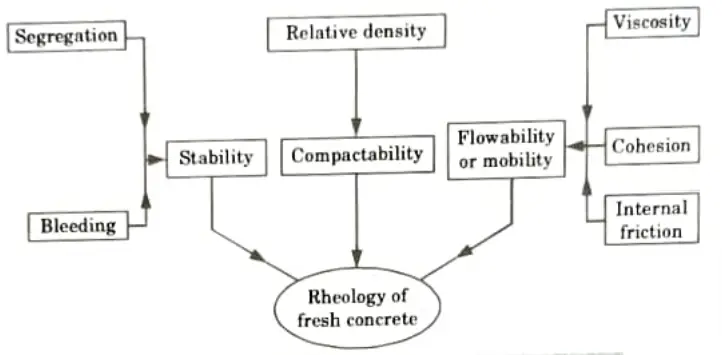

Parameters of Rheology: Following are the parameter of rheology:

1. Stability:

- i. It is described as a situation in which the matrix holds the aggregate particles in homogenous dispersion and a random sample reveals the same particle size distribution during placement, compaction, and transportation.

- ii. The stability of concrete is measured by its segregation and bleeding characteristics.

2. Mobility:

- i. Fresh concrete’s mobility is defined as its capacity to flow when subjected to mechanical loads, or when momentum is transferred. Cohesive, viscous, and frictional forces limit the flow.

- ii. The cohesive force is created by the aggregate particles’ adherence to the matrix. Fresh concrete’s tensile strength, which resists segregation, is provided.

- iii. The matrix’s viscosity influences how easily the aggregate particles can move around and reorganize themselves in the matrix.

- iv. When a mixture is moved, the aggregate particles spin and translate, creating internal friction.

- v. The water-cement ratio, the type of cement used, the richness of the mixture, the shape and texture of the aggregate all affect the resistance to deformation.

3. Compactability:

- i. It gauges how easily new concrete can be compacted.

- ii. Compacting involves releasing trapped air and moving the aggregate particles into a compact mass without producing segregation.

- iii. The compacting factor test determines compatibility.

Q5. Explain the affective factors of rheological properties of concrete.

Ans. Following are the affecting factors of rheological properties of concrete:

- 1. MixProportion: A concrete mix with too much coarse aggregate won’t have enough mortar to cover the void system, which will reduce the concrete’s cohesion and mobility.

- 2. Consistency: The relative water content in the concrete mix can be determined by the slump test, which measures the consistency of the concrete.

- 3. Hardening and Stiffening:

- i. A higher temperature, the use of cement that hardens more quickly, cement that lacks gypsum, and the use of accelerating admixtures all cause concrete to become less mobile.

- ii. By absorbing water from the mixture or increasing the surface area that needs to be wetted, the dry and porous aggregate will quickly impair workability.

- 4. Aggregate Shape and Texture:

- i. Because more voids will need to be filled by mortar as a result of the coarse and highly angular aggregate particles, there will need to be more fine aggregate and water in the mortar.

- ii. Similar to well-rounded natural sand, an angular fine aggregate can cause more internal friction in the concrete mixture and demand more water.

- 5. Aggregate Grading: An aggregate with good gradation has good workability. In contrast to coarse aggregate, these effects are more pronounced in fine aggregate.

- 6. Maximum Aggregate Size: The amount of fine aggregate that must be present to maintain a particular workability will decrease with an increase in the maximum size of aggregate, which will also decrease the amount of surface that needs to be wetted.

- 7. Admixtures: The admixtures which have significant effect on the rheology of concrete are plasticizers and super-plasticizers, air entraining agents, accelerators and retarders.

Q6. Write short note on quality control of concrete.

Ans.

- 1. The strength of concrete varies from batch to batch over a period of time.

- 2. Variations in the quality of the constituent materials, variations in mix proportions due to batching, variations in the quality of the available batching and mixing equipment, and variations in the quality of supervision and workmanship may all be considered as sources of variability in the strength of concrete.

- 3. To varied degrees, these variances are unavoidable during production.

- 4. It’s crucial to keep these variations under control in order to reduce the cement content by lessening the gap between the mix’s minimum strength and its mean strength.

- 5. Quality control is the determining factor in this discrepancy.

- 6. The variation in test findings, which is typically reported in terms of the coefficient of variation, is finally used to assess the level of control.

Important Question with solutions | AKTU Quantums | Syllabus | Short Questions

Concrete Technology Btech Quantum PDF, Syllabus, Important Questions

| Label | Link |

|---|---|

| Subject Syllabus | Syllabus |

| Short Questions | Short-question |

| Question paper – 2021-22 | 2021-22 |

Concrete Technology Quantum PDF | AKTU Quantum PDF:

| Quantum Series | Links |

| Quantum -2022-23 | 2022-23 |

AKTU Important Links | Btech Syllabus

| Link Name | Links |

|---|---|

| Btech AKTU Circulars | Links |

| Btech AKTU Syllabus | Links |

| Btech AKTU Student Dashboard | Student Dashboard |

| AKTU RESULT (One View) | Student Result |